Method and system for synthesizing p-acetaminobenzenesulfonyl chloride with sulfur trioxide as sulfonating agent

A technology of acetaminobenzenesulfonyl chloride and sulfur trioxide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of additive influence, high processing cost, large amount of chlorosulfonic acid, etc., and achieve saving Disposal cost, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

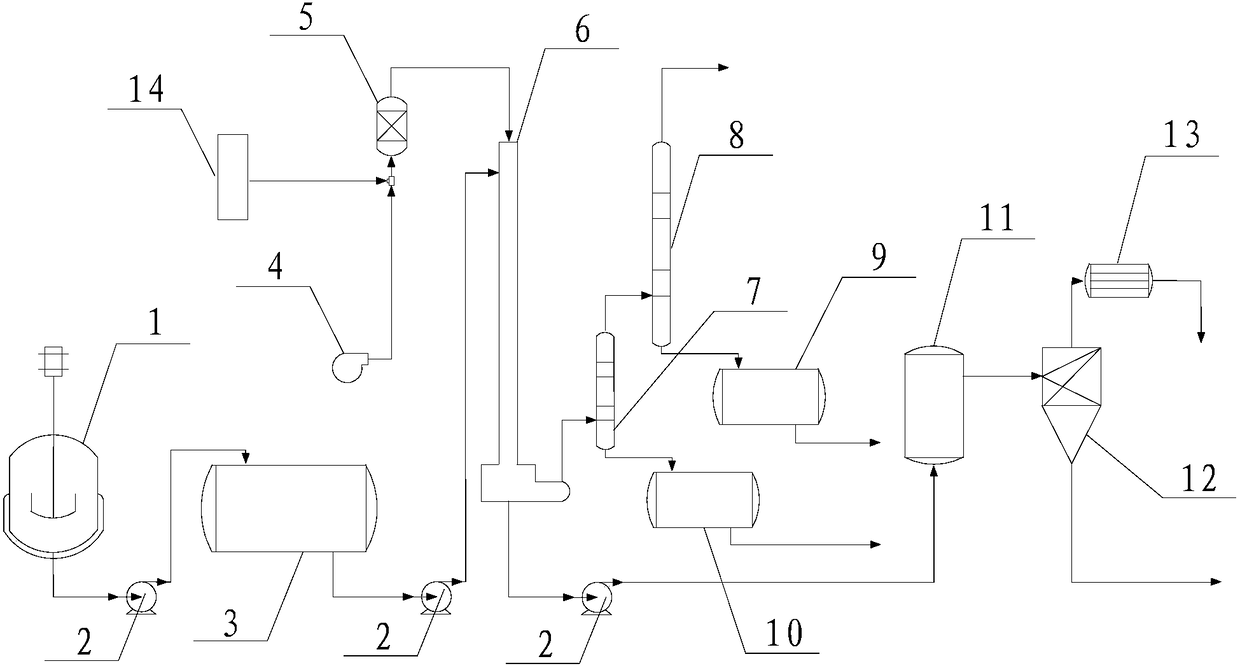

[0018] This embodiment provides a system for the synthesis of acetaminobenzenesulfonyl chloride with sulfur trioxide as a sulfonating agent, such as figure 1 As shown, it mainly includes a stirring batching tank 1, a pump 2, a storage tank 3 and a membrane reactor 6, etc.

[0019] Among them, the stirring batching tank 1 is used to stir and mix the reaction materials; the storage tank 3 is connected to the bottom of the stirring batching tank 1 through a pipeline, and a pump 2 is installed on the pipeline between them, and the stirring batching tank can be mixed by using the pump 2 The material in tank 1 is pumped into storage tank 3. The membrane reactor 6 is also communicated with the storage tank 3 through a pipeline, and another pump 2 is installed on the pipeline between them, and the reaction material stored in the storage tank 3 can be introduced into the membrane reactor 6 by the pump 2 react in. Sulfur trioxide gas storage tank 14 is in communication with membrane r...

Embodiment 2

[0022] The present embodiment provides a method for the synthesis of acetaminobenzenesulfonyl chloride with sulfur trioxide as a sulfonating agent, which comprises the following steps:

[0023] (a) Add 13.5kg of acetanilide and 30kg of thionyl chloride to the reactor in sequence, and stir to raise the temperature to 40°C;

[0024] (b) Slowly feed sulfur trioxide gas into the reactor (the flow rate of ventilation is 2.5L / min), and react at 40°C for 15 hours (the tail gas is absorbed by 1mol / L sodium carbonate solution); when the end of the reaction is approaching, every Sampling and analysis for 15 minutes (use HPLC for analysis), until the conversion of acetanilide is complete, stop feeding sulfur trioxide gas;

[0025] (c) Raise the temperature in the reactor to 70°C, recover the thionyl chloride under reduced pressure (the recovery quality is 17.5kg), and cool to obtain the crude p-acetaminobenzenesulfonyl chloride (purity: 98%, yield: 97%).

Embodiment 3

[0027] The present embodiment provides a method for the synthesis of acetaminobenzenesulfonyl chloride with sulfur trioxide as a sulfonating agent, which comprises the following steps:

[0028] (a) Add 13.5kg of acetanilide and 60kg of thionyl chloride to the reactor in sequence, and stir to raise the temperature to 70°C;

[0029] (b) Slowly feed sulfur trioxide gas into the reactor (the flow rate of ventilation is 13.0L / min), and react at 70°C for 3 hours (the tail gas is absorbed by 1mol / L sodium carbonate solution); when the end of the reaction is approaching, every Sampling and analysis for 5 minutes (use HPLC for analysis), until the conversion of acetanilide is complete, stop feeding sulfur trioxide gas;

[0030] (c) Raise the temperature in the reactor to 80°C, recover the thionyl chloride under reduced pressure (recovered mass is 17.1kg), and cool to obtain the crude p-acetaminobenzenesulfonyl chloride (purity: 96%, yield: 98%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com