Powder oil shale dry distillation system device and application method thereof

A system device and oil shale technology, applied in special forms of dry distillation, petroleum industry, coking oven, etc., can solve the problems of difficult sewage treatment, unsmooth, low equipment production capacity, etc., achieve large-scale and automation, and improve resource utilization The effect of high rate and labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

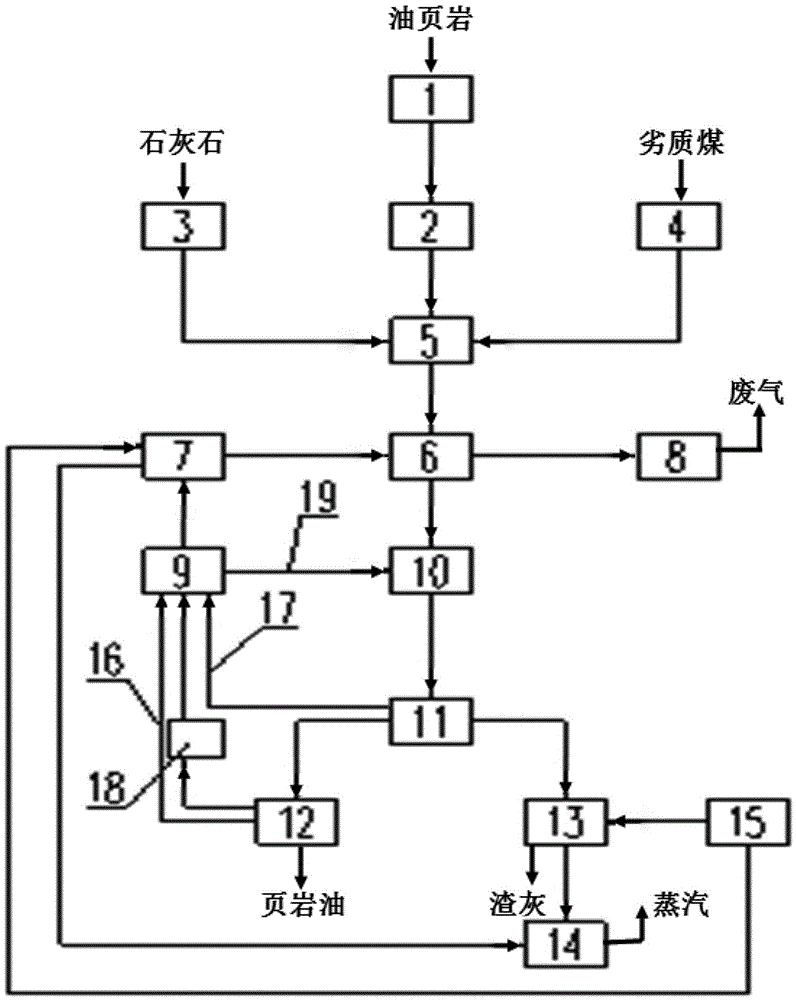

[0023] A kind of novel powdery oil shale dry distillation system device structure of the implementation of the present invention is as follows figure 1 shown.

[0024] The new powdery oil shale retort system device of the present invention is mainly composed of a crushing unit 1, a homogenization unit 2, a low-quality coal mixing unit 3, a desulfurizer adding unit 4, a grinding unit 5, a drying preheater 6, and flue gas waste heat Boiler 7, flue gas treatment unit 8, suspension heat carrier furnace 9, rapid dry distillation reactor 10, high temperature gas-solid separator 11, oil gas recovery device 12, powder waste heat boiler 13, steam output unit 14, boiler water supply unit 15, oil The slag delivery pipe 16, the solid discharge pipe 17, the combustion station 18 and the heat carrier circulation pipe 19 are composed, wherein: the discharge port of the crushing unit 1 is connected with the feed port of the homogenization unit 2, and the distribution port of the homogenizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com