Preparation method for optical table for observing osteocyte

An optical platform, bone cell technology, applied in the fields of medical science, pharmaceutical formulations, prostheses, etc., can solve the problem that the growth and state of cells cannot be observed with an optical microscope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

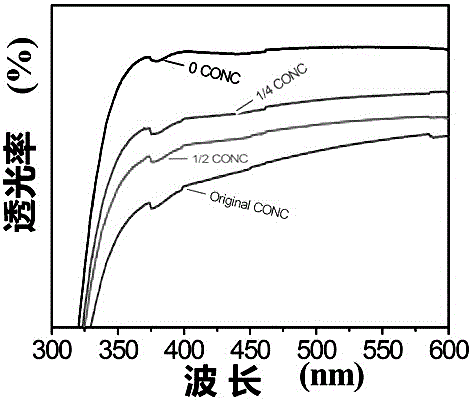

[0031] Weigh 0.5968g of calcium nitrate tetrahydrate and dissolve it completely with 50mL of deionized water to obtain a calcium nitrate solution.

[0032] Weigh 0.1996g of diammonium hydrogen phosphate and dissolve it completely with 50mL of deionized water to obtain ammonium dihydrogen phosphate solution.

[0033] Under the condition of magnetic stirring, the ammonium dihydrogen phosphate solution was slowly added to the calcium nitrate solution for reaction, and the pH of the reaction system was adjusted to 10 by ammonia water during the addition process to obtain a white hydroxyapatite suspension.

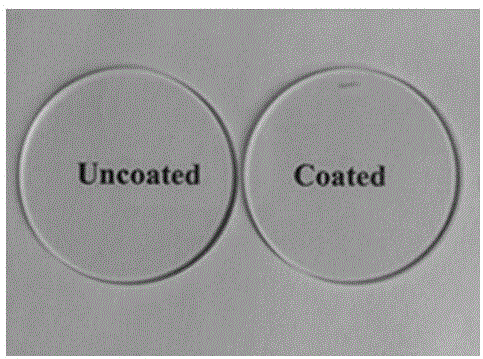

[0034] After the treated glass substrate is placed in the polytetrafluoroethylene reaction liner, hydroxyapatite suspension is added to the liner.

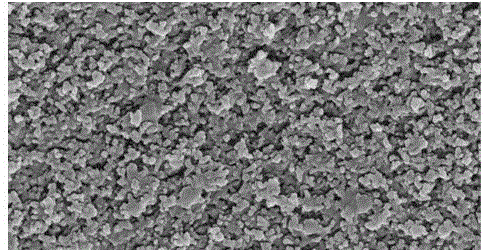

[0035] Put the autoclave in an oven for hydrothermal reaction at 180°C for 24 hours. After the reaction was completed and cooled to room temperature, the sample was ultrasonically washed for 5 minutes to remove the unstable hydroxy...

Embodiment example 2

[0037] Weigh 0.2984g calcium nitrate tetrahydrate and dissolve completely with 50mL deionized water to obtain calcium nitrate solution.

[0038] Weigh 0.0998g of diammonium hydrogen phosphate and dissolve it completely with 50mL of deionized water to obtain ammonium dihydrogen phosphate solution.

[0039] Under the condition of magnetic stirring, the ammonium dihydrogen phosphate solution was slowly added to the calcium nitrate solution for reaction, and the pH of the reaction system was adjusted to 10 by ammonia water during the addition process to obtain a white hydroxyapatite suspension.

[0040] After the treated glass substrate is placed in the polytetrafluoroethylene reaction liner, hydroxyapatite suspension is added to the liner.

[0041] Put the autoclave in an oven for hydrothermal reaction at 180°C for 24 hours. After the reaction was completed and cooled to room temperature, the sample was ultrasonically washed for 5 minutes to remove the unstable hydroxyapatite att...

Embodiment example 3

[0043] Weigh 0.1492g of calcium nitrate tetrahydrate and dissolve it completely with 50mL of deionized water to obtain a calcium nitrate solution.

[0044] Weigh 0.0449g of diammonium hydrogen phosphate and dissolve it completely with 50mL of deionized water to obtain ammonium dihydrogen phosphate solution.

[0045] Under the condition of magnetic stirring, the ammonium dihydrogen phosphate solution was slowly added to the calcium nitrate solution for reaction, and the pH of the reaction system was adjusted to 10 by ammonia water during the addition process to obtain a white hydroxyapatite suspension.

[0046] After the treated glass substrate is placed in the polytetrafluoroethylene reaction liner, hydroxyapatite suspension is added to the liner.

[0047] Put the autoclave in an oven for hydrothermal reaction at 180°C for 24 hours. After the reaction was completed and cooled to room temperature, the sample was ultrasonically washed for 5 minutes to remove the unstable hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com