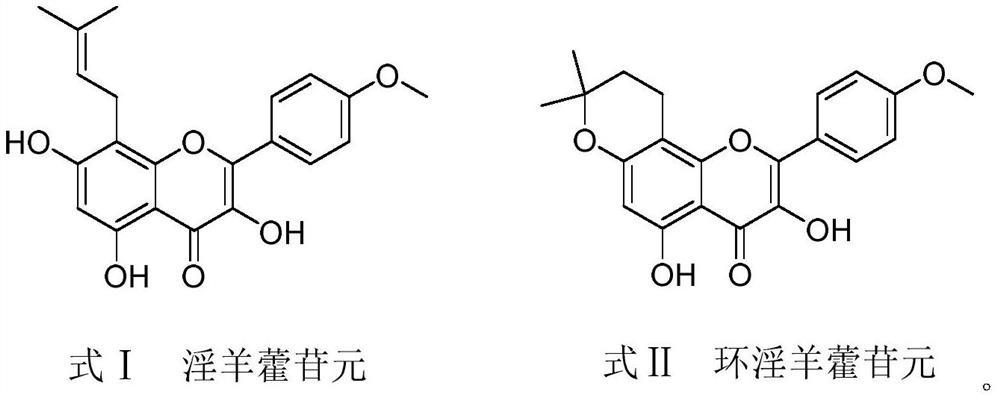

Icaritin tablet and preparation method therefor

A technology of aurigenin tablets and icarigenin, which is applied in the field of medicine and can solve the problems of limited drug loading capacity, complicated preparation process, and low oral absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

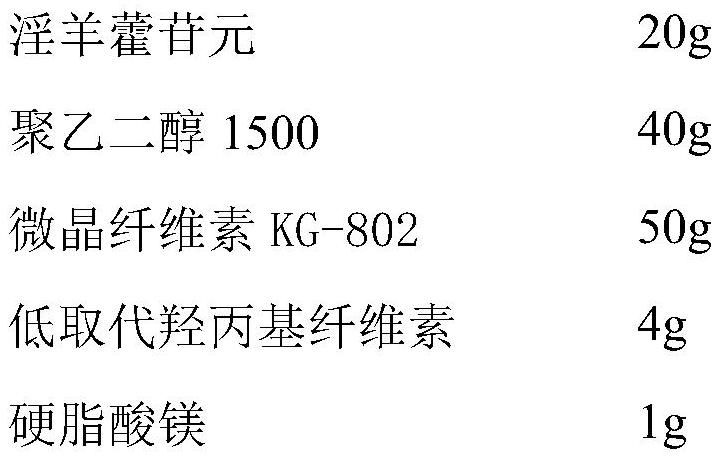

Embodiment 1

[0052] (1) Prescription

[0053]

[0054] (2) Preparation process

[0055] The icariin was crushed through an 80-mesh sieve, and set aside; the prescribed amount of icariin and 20 g of polyethylene glycol 1500 were added to the fluidized bed, and the temperature was set at 45° C., and melt granulation was carried out in the fluidized bed; Melt granulation for 3 minutes, immediately add the prescribed amount of microcrystalline cellulose KG-802, low-substituted hydroxypropyl cellulose and the remaining 20 g of polyethylene glycol 1500, continue granulation for 5 minutes, and pass through a 20-mesh sieve while hot after granulation Whole grains, finally add the prescribed amount of magnesium stearate, mix evenly, and press into tablets to obtain icarigenin tablets.

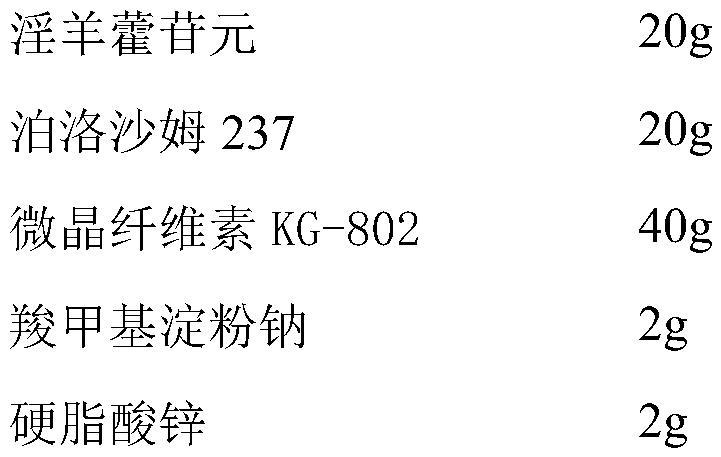

Embodiment 2

[0057] (1) Prescription

[0058]

[0059] (2) Preparation process

[0060] The icariin was crushed through an 80-mesh sieve, and set aside; the prescribed amount of icariin and 10 g of poloxamer 237 were added to the fluidized bed, and the temperature was set at 45 ° C, and melt granulation was carried out in the fluidized bed; Melt granulation for 3 minutes, immediately add the prescribed amount of microcrystalline cellulose KG-802, sodium carboxymethyl starch and the remaining 10 g of poloxamer 237, and continue granulation for 5 minutes. After granulation is completed, the granules are passed through a 20-mesh sieve while hot , and finally add the prescribed amount of magnesium stearate, mix evenly, and press into tablets to obtain icariin tablets.

Embodiment 3

[0062] (1) Prescription

[0063]

[0064]

[0065] (2) Preparation process

[0066] The icariin was crushed through an 80-mesh sieve, and set aside; the prescribed amount of icariin and 27 g of polyethylene glycol 4000 were added to the fluidized bed, and the temperature was set at 50 ° C, and melt granulation was carried out in the fluidized bed; Melt granulation for 4 minutes, immediately add the prescribed amount of microcrystalline cellulose PH-102, low-substituted hydroxypropyl cellulose and the remaining 33 g of polyethylene glycol 4000, continue granulation for 6 minutes, and pass through a 20-mesh sieve while hot after granulation Whole grains, and finally add the prescribed amount of zinc stearate, mix evenly, and press into tablets to obtain icariin tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com