A biological scaffold material for root regeneration, preparation method and application thereof

A biological scaffold and scaffold material technology, applied in the field of medical materials, can solve the problems of weak stem cell directional differentiation function, lack of cell adhesion and differentiation, unable to maintain stem cell activity, etc., and achieve good biocompatibility, natural ingredients, and volume. and the effect of increasing the inner surface area of the tubules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

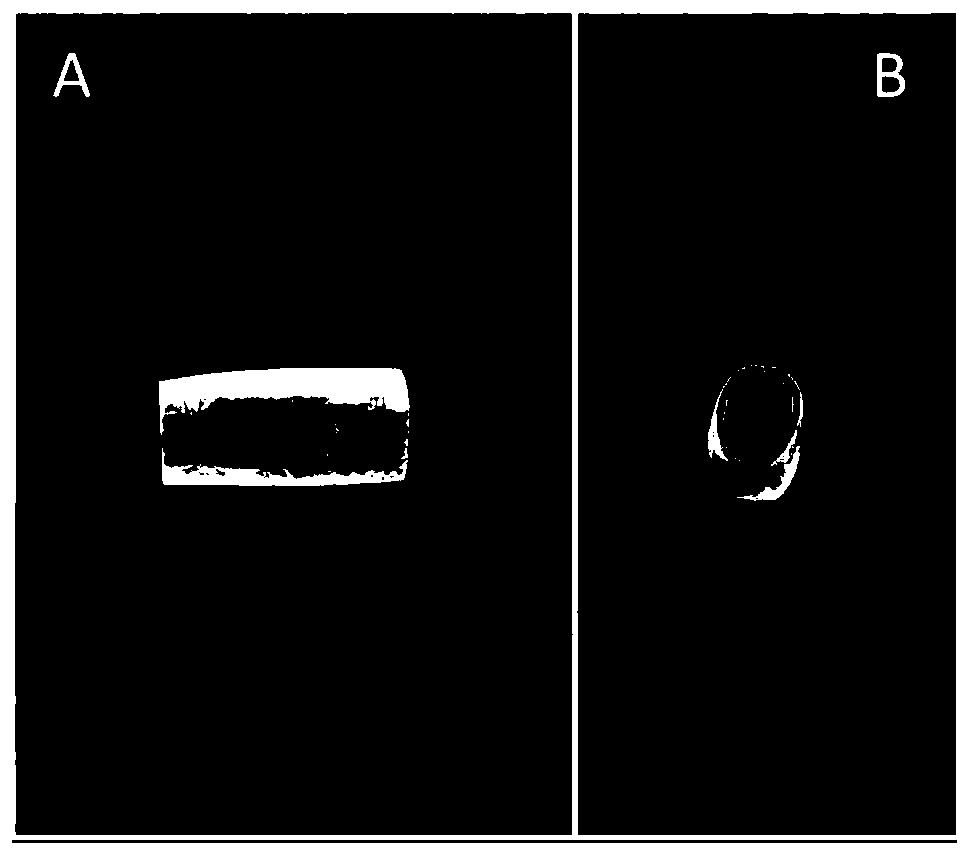

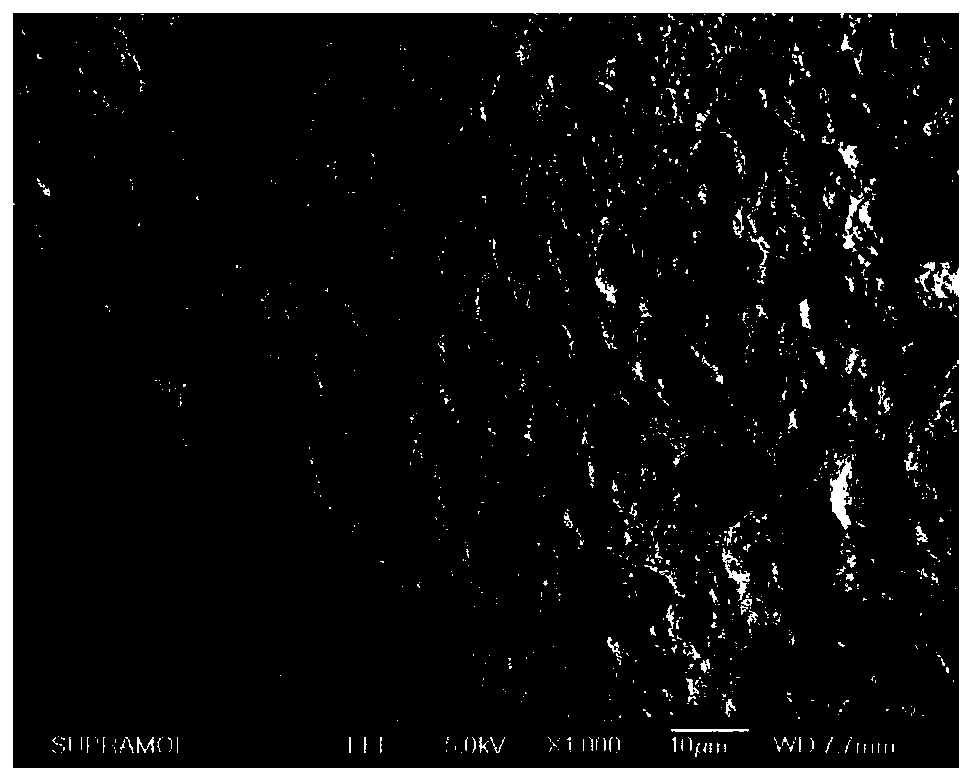

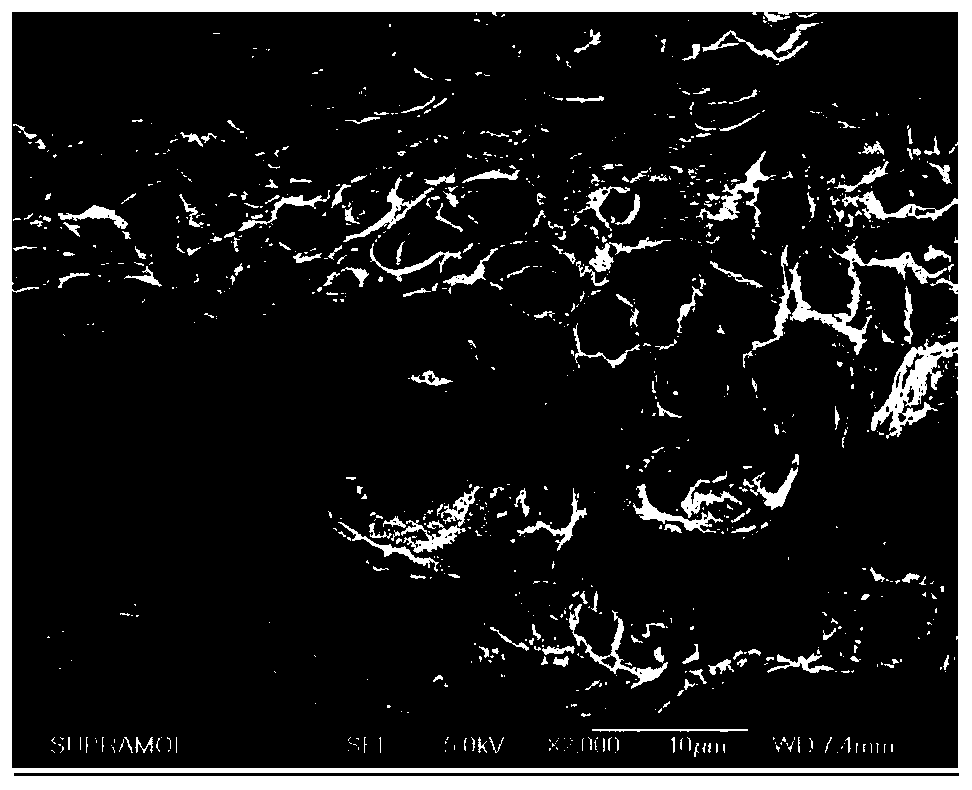

[0032] Example 1: Preparation of dentin scaffold material derived from bovine teeth.

[0033] (1) Take bovine milk incisors, intercept the upper 1 / 3 part of the root, and remove the pulp tissue;

[0034] (2) Remove the pulp and part of the predentin along the inner side of the pulp cavity of the root, and remove the cementum and part of the dentin according to the shape of the root to obtain a 1 mm thick and 1.1 cm long dentin. Scaffolds;

[0035] (3) The scaffold material was placed in water, treated in an ultrasonic oscillator for 30 minutes, and dried at 60°C.

[0036] (4) Place the dried scaffold material in an aqueous formic acid solution with a mass fraction of 20%, and quickly put the whole system under a negative pressure of 5Kpa for 3 minutes.

[0037] (5) Take out the scaffold material treated in step (4), quickly blow off the acid on its surface, and place it at room temperature for 10 minutes.

[0038] (6) The scaffold material was placed in water, treated in an...

Embodiment 2

[0042] Example 2: Preparation of dentin scaffold material derived from porcine teeth.

[0043] (1) Take pig mandibular lateral incisors, intercept the upper 1 / 3 part of the root, and remove the pulp tissue;

[0044] (2) Remove the pulp and part of the predentin along the inside of the pulp cavity of the root, and remove the cementum and part of the dentin according to the shape of the root to obtain a dentin layer with a thickness of 1.5 mm and a length of 1.2 cm the support material;

[0045] (3) The scaffold material was placed in water, treated in an ultrasonic oscillator for 30 minutes, and dried at 80°C.

[0046] (4) Place the dried scaffold material in an aqueous formic acid solution with a mass fraction of 20%, and quickly put the whole system under a negative pressure of 5Kpa for 1 minute.

[0047] (5) Take out the scaffold material treated in step (4), quickly blow off the acid on its surface, and place it at room temperature for 15 minutes.

[0048] (6) The scaffo...

Embodiment 3

[0052] Example 3: Preparation of dentin scaffold material derived from human teeth.

[0053] (1) Take the mandibular first premolar, cut off the upper 1 / 2 part of the root, and remove the pulp tissue;

[0054] (2) Remove the pulp and part of the predentin along the inner side of the pulp cavity of the tooth root, and remove the cementum and part of the dentin according to the shape of the root to obtain a 0.5 mm thick and 5 mm long dentin. Scaffolds;

[0055] (3) The scaffold material was placed in water, treated in an ultrasonic oscillator for 20 minutes, and dried at 50°C.

[0056] (4) Place the dried scaffold material in an aqueous formic acid solution with a mass fraction of 10%, and quickly place the whole system under a negative pressure of 5Kpa for 2 minutes.

[0057] (5) Take out the scaffold material treated in step (4), quickly blow off the acid on its surface, and place it at room temperature for 30 minutes.

[0058] (6) The scaffold material was placed in water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com