Method for extracting propolis step by step with subcritical fluid

A subcritical fluid and extraction technology, applied in solid solvent extraction, food science, etc., can solve the problems of incomplete extraction of active components, excessive heavy metal content, deep color of the extract, etc., to reduce extraction costs, low operating costs, The effect of low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

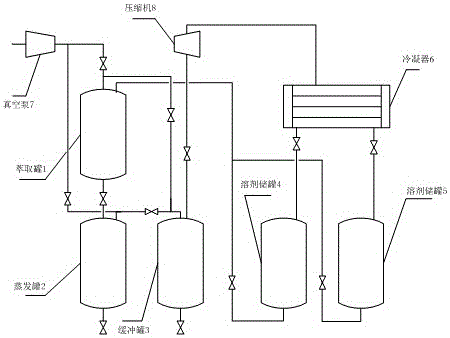

Image

Examples

example 1

[0024] Weigh 1000g of fur glue (content: 40.7%), freeze at -20°C for 48 hours and pulverize to 0.1-2 mm coarse particles; put the crushed fur glue into a 300-mesh silk bag, tie the mouth, put Put it into the extraction kettle of the subcritical extraction device, vacuumize, add 5200 mL of liquefied butane gas, extract 3 times at 23 ° C, and extract for 40 minutes each time; the extract is transferred to the evaporation tank 2 for evaporation, compressed and cooled by the compressor Then put it in the solvent storage tank 4 for recycling; desolvate the evaporation tank 2 for 40 minutes under negative pressure of -0.09MPa, take out the extract, and obtain 186g of beeswax. Precipitate and vacuumize the extraction tank 2, add 6100 mL of liquefied tetrafluoroethane, extract 3 times at 30°C, and extract for 50 minutes each time; transfer the extract to the evaporation tank 2, evaporate, and desolventize under negative pressure to obtain light-colored The refined propolis extract was...

example 2

[0026] Weigh 1000g of fur glue (content: 23.4%), freeze at -20°C for 48 hours and pulverize to 0.1-2 mm coarse particles; put the crushed fur glue into a 300-mesh silk bag, tie the mouth, put Put it into the extraction kettle of the subcritical extraction device, vacuumize, add 3100 mL of liquefied propane gas, and extract 3 times at 20°C for 30 minutes each time; the extract is transferred to the evaporation tank 2 for evaporation, compressed and cooled by the compressor Put it in the solvent storage tank 4 for recycling; desolvate the evaporation tank 2 for 20 minutes under negative pressure of -0.09MPa, take out the extract, and obtain 107g of beeswax. Desolventize in extraction tank 2, vacuumize, add 2100 mL of liquefied tetrafluoroethane, extract 3 times at 30°C, and extract for 40 minutes each time; transfer the extract to evaporation tank 2, evaporate, and desolventize under negative pressure to obtain light-colored The refined propolis extract was 125g, and the total f...

example 3

[0028] Weigh 500g of fur glue (content: 68.8%), freeze at -20°C for 48 hours and pulverize to 0.1-2 mm coarse particles; put the crushed fur glue into a 300-mesh silk bag, tie the mouth, put Put it into the extraction kettle of the dual-solvent subcritical extraction device, vacuumize, add 5000 mL of liquefied butane gas, extract 3 times at 25 ° C, and extract for 60 minutes each time; the extract is transferred to evaporation tank 2 for evaporation, and compressed by a compressor 1. After cooling, put it in the solvent storage tank 4 for recycling; desolventize the evaporation tank 2 for 60 minutes under negative pressure of -0.09MPa, take out the extract, and obtain 157g of beeswax. Desolventize in extraction tank 2, vacuumize, add 4000 mL of liquefied dimethyl ether, extract 4 times at 55°C, and extract for 70 minutes each time; transfer the extract to evaporation tank 2, evaporate, and desolventize under negative pressure to obtain light-colored refined The propolis extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com