A kind of rosin-based tertiary ammonium surfactant and its preparation method and application

A surfactant and tertiary ammonium-based technology, which is applied in the field of rosin-based tertiary ammonium surfactants and their preparation, can solve the problems of limited types and achieve good surface activity and antibacterial activity, excellent water solubility and emulsifying ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

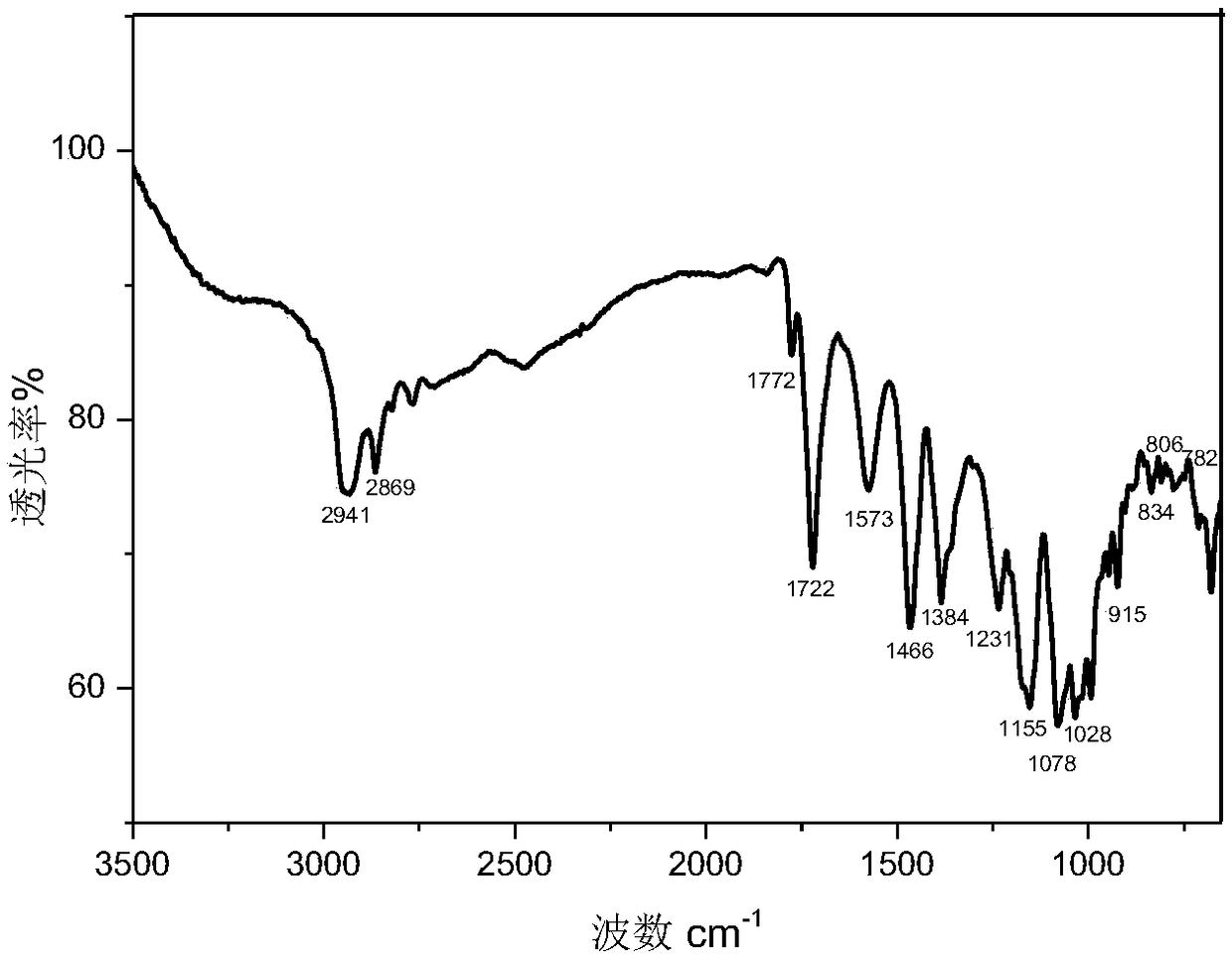

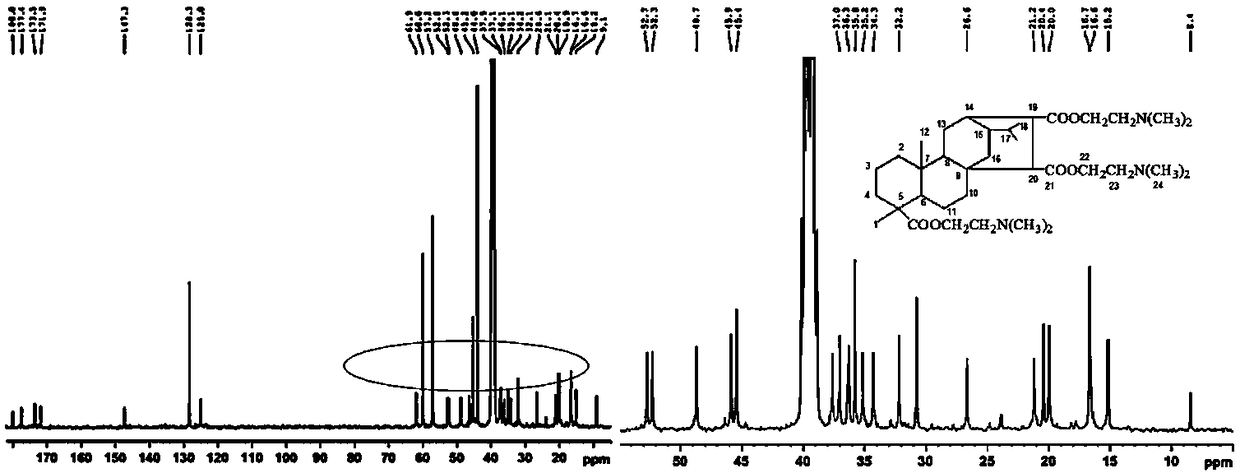

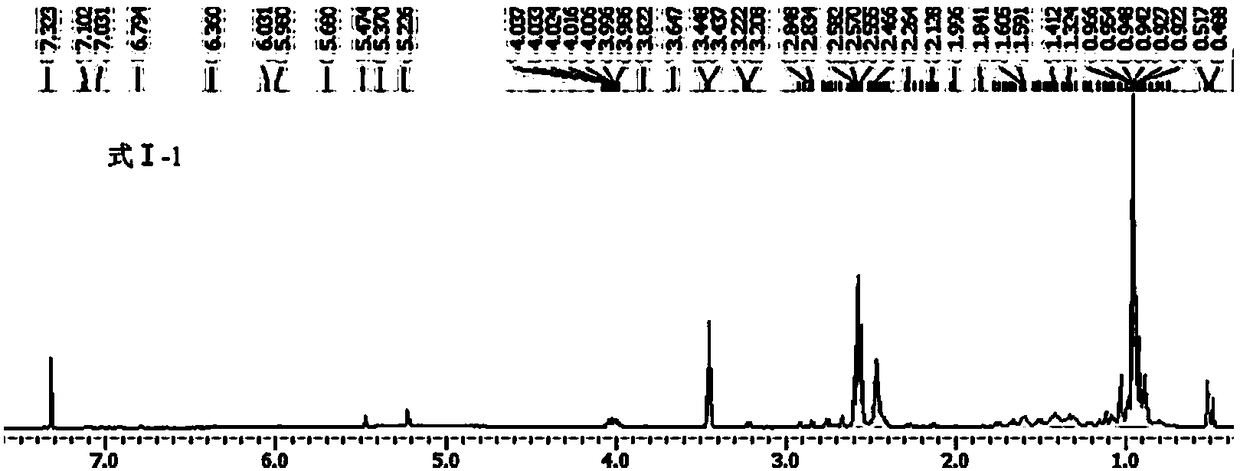

[0033] The preparation of embodiment 1 formula Ⅰ-1 compound

[0034]

[0035] Dissolve 0.01mol maleated rosin acid chloride in 15ml benzene solution, then slowly add it dropwise to 0.04mol N,N-dimethylethanolamine benzene solution, the mixture of modified rosin acid chloride and N,N-dimethylethanolamine The molar ratio was 1:4. After 5 minutes, 4 mL of triethylamine was added dropwise as an acid-binding agent. After reacting for 3 hours at room temperature, viscous compound I-1 was obtained by rotary evaporation.

[0036] Using the same method as in Example 1, replacing N,N-dimethylethanolamine with other alcohols with 1-5 carbon atoms (not 1), the compound of formula I in which n is 1-5 (not 1) can be obtained is the compound of 1).

Embodiment 2

[0037] The preparation of embodiment 2 formula Ⅰ-2 compound

[0038]

[0039] Dissolve 0.01mol maleated rosin acid chloride in 15ml benzene solution and slowly add dropwise to 0.04mol N,N-diethylethanolamine benzene solution, the molar ratio is 1:4, after 5 minutes, add 4mL triethylamine dropwise Acid-binding agent, after reacting at room temperature for 3 hours, viscous compound I-2 was obtained by rotary evaporation.

[0040] Using the same method as in Example 2, replacing N,N-diethylethanolamine with other alcohols with 1-5 carbon atoms (not 1), the compound of formula I in which n is 1-5 (not 1) can be obtained is the compound of 1).

Embodiment 3

[0041] The preparation of embodiment 3 formula Ⅱ-1 compound

[0042]

[0043] Dissolve 0.05 mol of acrylic acid-modified rosin acid chloride in 75 ml of benzene solution and slowly add it dropwise to 0.15 mol N,N-dimethylethanolamine benzene solution, the molar ratio is 1:3, after 5 minutes, add 5 mL of triethylamine to bind Acid agent, reacted at room temperature for 3 hours, and then evaporated to obtain viscous compound Ⅱ-1.

[0044] Using the same method as in Example 3, replacing N,N-dimethylethanolamine with other alcohols with a carbon number of 1-5 (not 1), the compound of formula II in which n is 1-5 (not 1) can be obtained is the compound of 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com