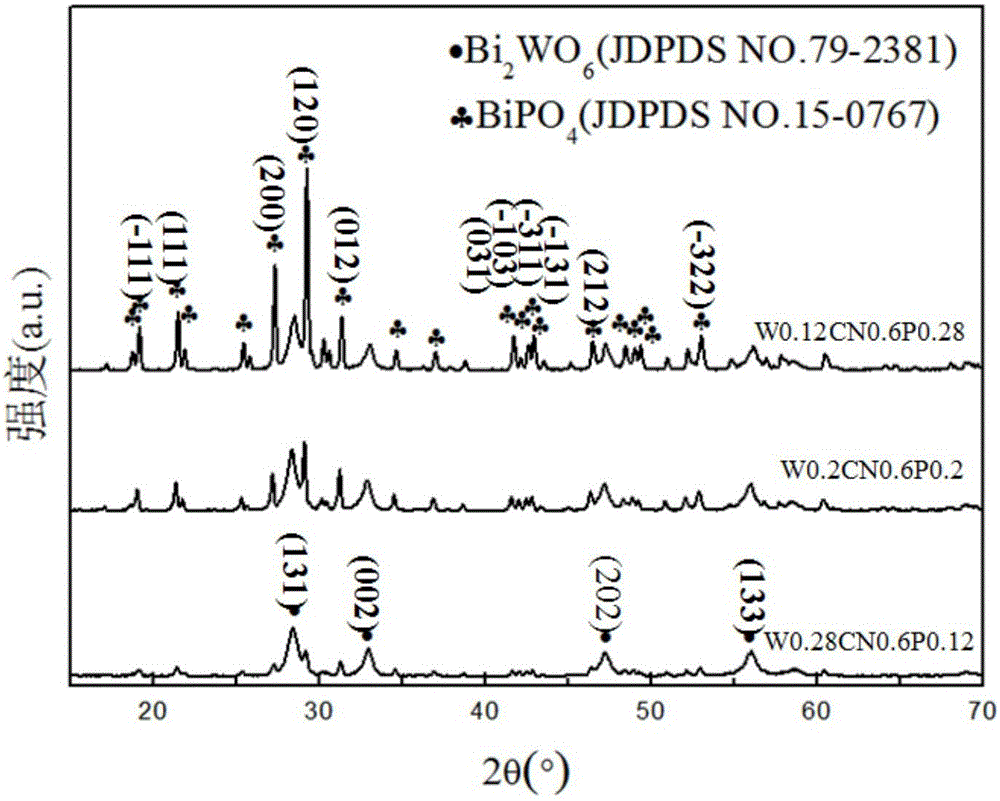

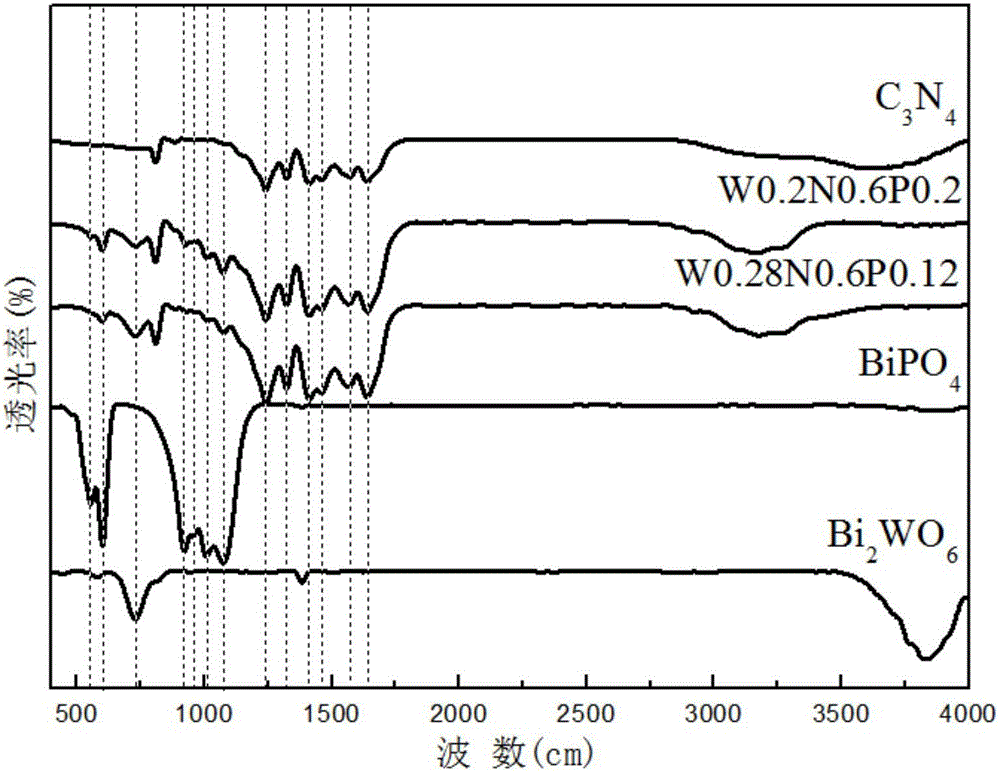

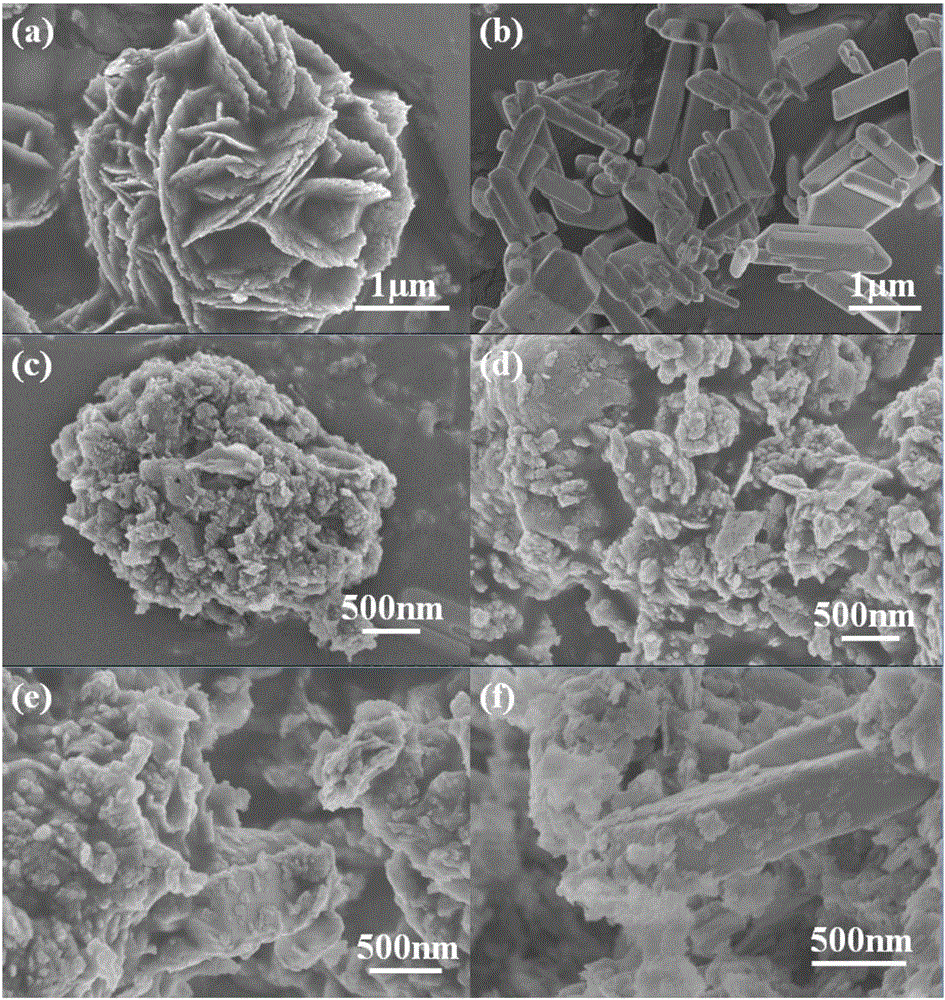

Bismuth tungstate/carbon nitride/bismuth phosphate composite photocatalyst as well as preparation method and application thereof

A technology of carbon nitride and bismuth phosphate, applied in physical/chemical process catalysts, chemical instruments and methods, water treatment of special compounds, etc., to achieve good adsorption performance, improve separation efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.133mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 400W for 30min, and then at room temperature with 300rad / L Min speed magnetic stirring for 2 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W, microwave hydrothermal reaction at 180°C for 1 hour, and a white mixed solution was obtained. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 80 °C for 15 h to obtain white Bi 2 WO 6 Powder;

[0039] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1, mix them evenly and add them into deionized water to obtain a mixture, the concentration of melamine and urea in the mixture is 0.333g / mL, and stir the m...

Embodiment 2

[0044] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water and stir vigorously for 20 minutes to obtain a white mixed solution. The concentration of Bi element in the mixed solution is 0.14mol / L. The mixed solution is ultrasonically dispersed in an ultrasonic instrument with a power of 500W for 20min, and then at room temperature at 200rad / L Magnetically stirred at a speed of min for 3 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W. Microwave hydrothermal reaction was carried out at 200°C for 0.5 hours to obtain a white mixed solution. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 70 °C for 16 h to obtain white Bi 2 WO 6 Powder;

[0045] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1.1, mix them evenly and add them into deionized water to obtain a mixture. The concentration of melamine and urea in the mix...

Embodiment 3

[0050] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.145mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 450W for 25min, and then at room temperature with 250rad / L Magnetically stirred at a speed of 2.5 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W. Microwave hydrothermal reaction was carried out at 190°C for 0.6 hours to obtain a white mixed solution. The mixed solution was left to stand for stratification, and the supernatant was removed. , the precipitate was washed three times with absolute ethanol and deionized water, and dried at 75 °C for 17 h to obtain white Bi 2 WO 6 Powder;

[0051] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1.2, mix them evenly and add them into deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com