A kind of preparation method of wood-like wood-plastic co-extrusion profile

A technology of extruding profiles and wood plastics, which is applied in the field of imitation wood-wood plastics co-extrusion profiles, which can solve the problems of unnatural appearance, poor UV resistance, easy fading and deformation, etc., to achieve a sense of hierarchy, not easy to fade, and slow aging speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

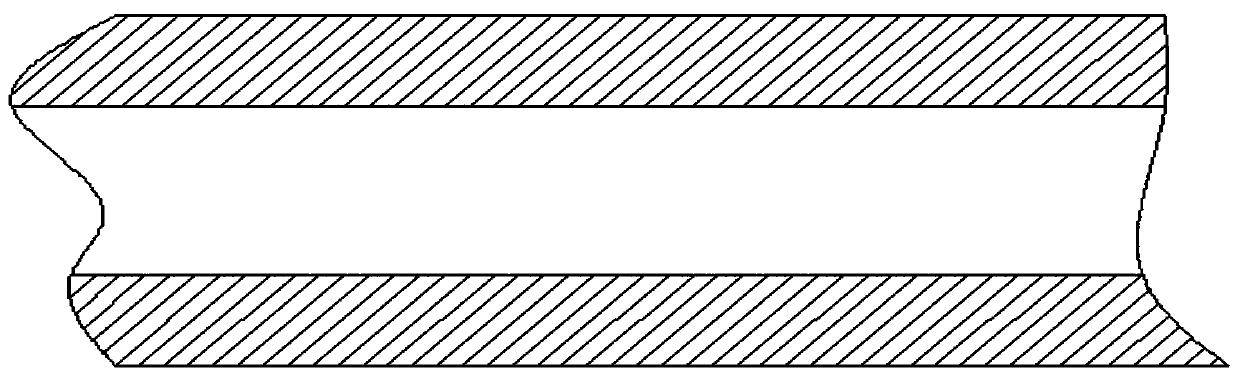

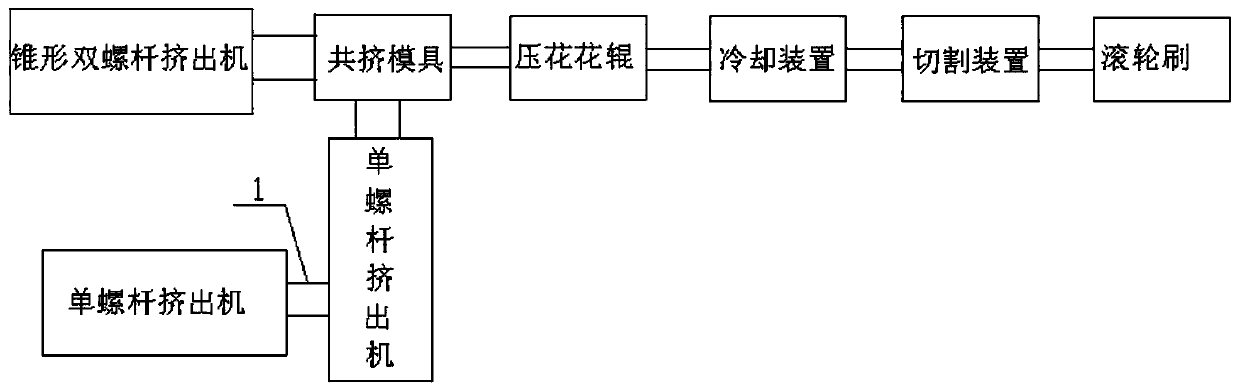

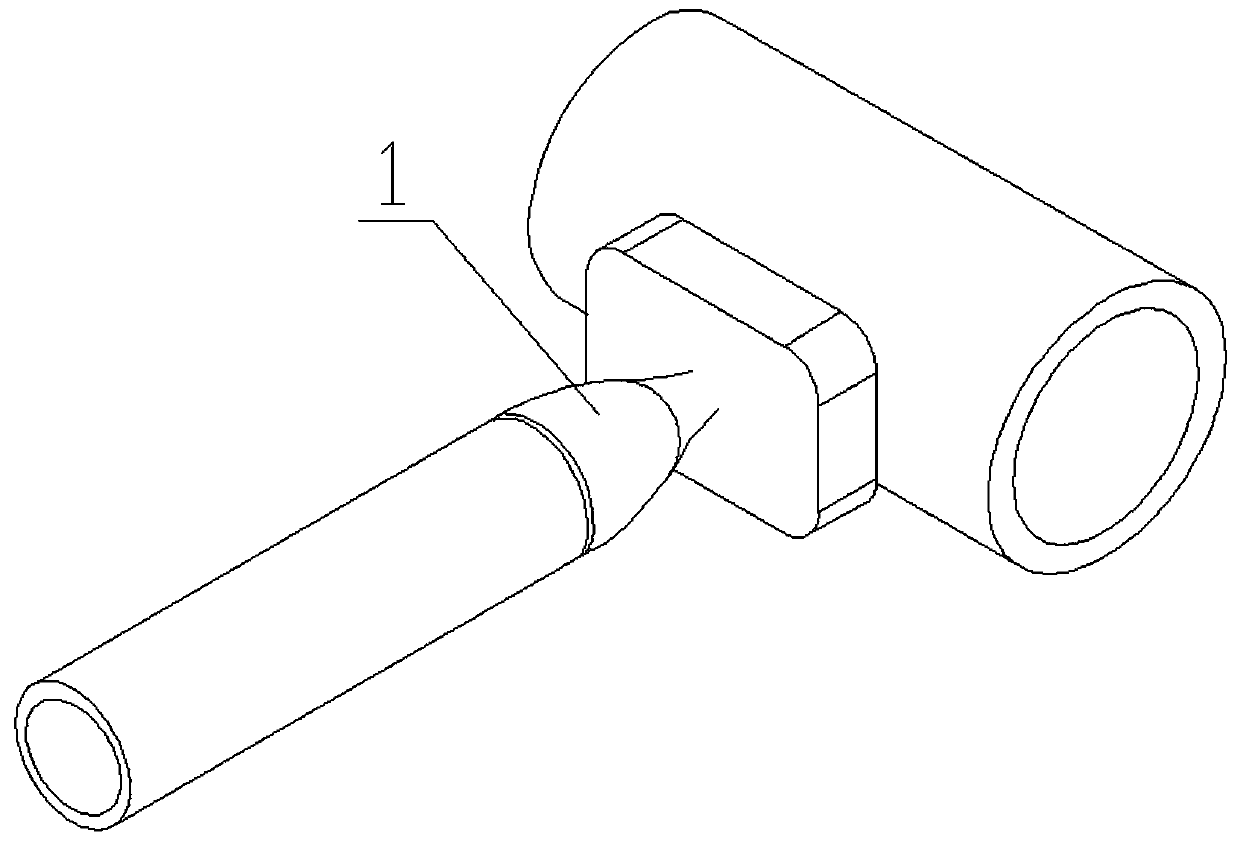

[0031] Such as figure 1 As shown, the slash part represents the outer layer, and the core layer is between the outer layer and the outer layer. A wood-like wood-plastic co-extrusion profile to be prepared, including a core layer and an outer layer, in parts by weight, the core layer raw materials include 55 parts of wood powder, 30 parts of plastic, 5 parts of lubricant, and 5 parts of coupling agent , 5 parts of toner; the outer layer raw materials include 53 parts of high-density polyethylene with a molecular weight range of 40,000-300,000, 30 parts of sarin resin, 6 parts of color masterbatch, and 4 parts of anti-ultraviolet masterbatch; the outer layer is wrapped on the surface of the core layer . The outer material also includes 1 part ethylene acrylic acid copolymer and 7 parts polypropylene.

[0032] Lubricants are used to reduce the melting pressure, improve fluidity, and obtain a suitable extrusion speed during the melting and extrusion of materials; coupling agents...

Embodiment 2

[0043] A wood-like wood-plastic co-extrusion profile prepared in this example includes a core layer and an outer layer. In parts by weight, the raw materials for the core layer include 55 parts of wood powder, 30 parts of plastic, 5 parts of lubricant, and a coupling agent. 5 parts, 5 parts of toner; the outer layer raw materials include 40 parts of high-density polyethylene with a molecular weight range of 40,000-300,000, 40 parts of sarin resin, 5 parts of color masterbatch, and 5 parts of anti-ultraviolet masterbatch; the outer layer is wrapped in the core layer surface. The outer material also includes 5 parts of ethylene acrylic acid copolymer and 5 parts of polypropylene.

[0044] In the composite process of wood and plastic materials, because there are a large number of polar hydroxyl groups on the surface of wood fiber, it is hydrophilic, while the surface of plastic is hydrophobic. In order to make the interface between the two compatible, ethylene acrylic acid copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com