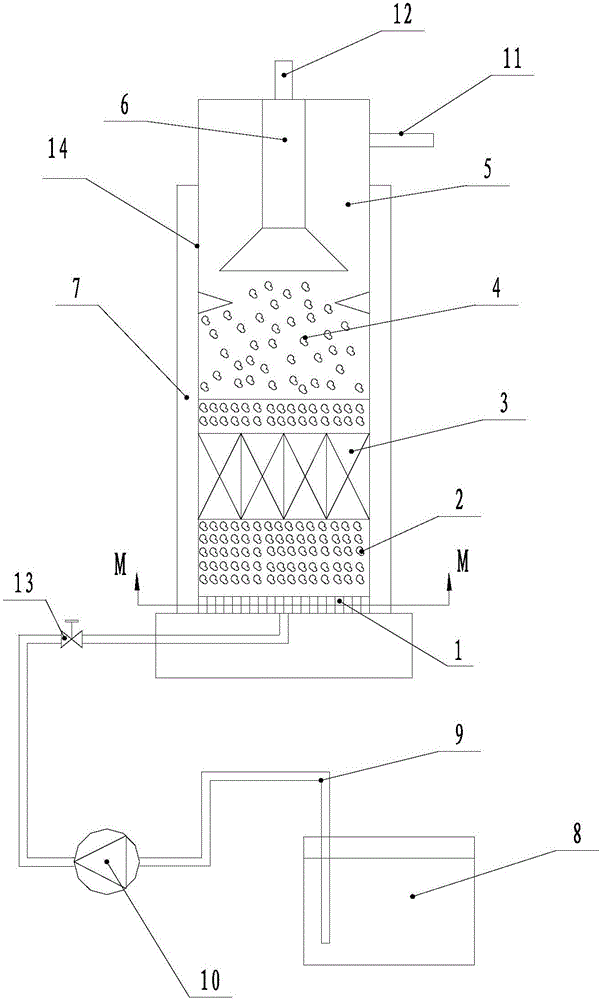

Method for accelerating anaerobic propionic acid and butyric acid decomposition by utilizing ethanol and charcoal

A biochar, butyric acid technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc. The effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

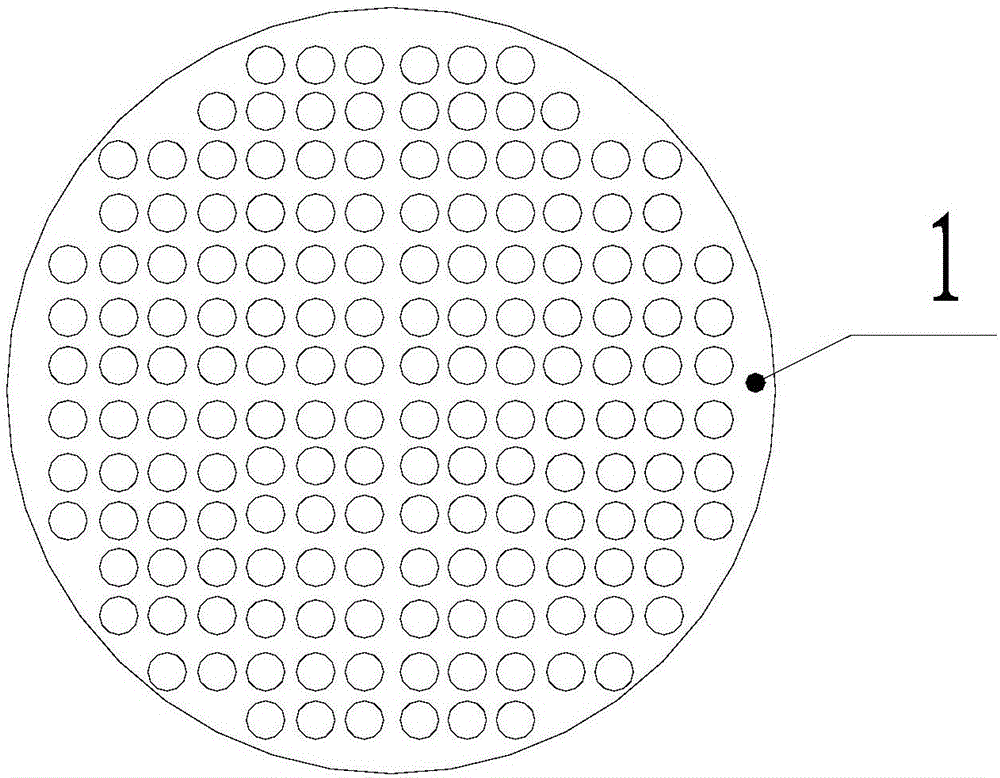

Embodiment 1

[0039] An upflow anaerobic digestion unit with an effective volume of 1L is inoculated with 400mL of anaerobic sludge, and the sludge concentration (MLSS) is 13g / L. The concentration of propionic acid in wastewater is 5137.5mgCOD / L. Analytical pure ethanol with a concentration ≥ 99.7% was added to the wastewater according to the COD ratio of 4:1, and the anaerobic digestion device was operated for 15 days. The pH in the anaerobic digestion unit is controlled at 7.2, and the temperature is controlled at 37°C. The hydraulic retention time of the anaerobic digestion unit is controlled at 12 hours. Weigh 5g of biochar (flaky, particle size 20-30mm) and add it to the biochar filling layer in the anaerobic digestion device, seal the anaerobic digestion device, and run the anaerobic digestion device for 15 days. Gradually reduce the amount of ethanol added in the wastewater, according to the COD ratio of ethanol and wastewater from 4:1 to 3:2, 2:3, 1:4, until the wastewater does no...

Embodiment 2

[0041] An upflow anaerobic digestion unit with an effective volume of 1L is inoculated with 400mL of anaerobic sludge, and the sludge concentration is 13g / L. The concentration of butyric acid in wastewater is 5137.5mgCOD / L. Analytical pure ethanol with a concentration ≥ 99.7% was added to the wastewater according to the COD ratio of 4:1, and the anaerobic digestion device was operated for 15 days. The pH in the anaerobic digestion unit is controlled at 7.2, and the temperature is controlled at 37°C. The hydraulic retention time of the anaerobic digestion unit is controlled at 12 hours. Take 5g of flake biochar with a particle size of 20-30mm and add it to the biochar filling layer in the anaerobic digestion device, seal the anaerobic digestion device, and run the anaerobic digestion device for 15 days. Gradually reduce the amount of ethanol added in the wastewater, and reduce the COD ratio of ethanol to wastewater from 4:1 to 3:2, 2:3, and 1:4 until there is no ethanol in th...

Embodiment 3

[0043] An upflow anaerobic digestion unit with an effective volume of 1L is inoculated with 350mL of anaerobic sludge, and the sludge concentration is 17g / L. The concentration of propionic acid in wastewater is 5031mgCOD / L. Analytical pure ethanol with a concentration ≥ 99.7% was added to the wastewater according to the COD ratio of 4:1, and the anaerobic digestion device was operated for 10 days. The pH in the anaerobic digestion unit is controlled at 7.2, and the temperature is controlled at 37°C. The hydraulic retention time of the anaerobic digestion unit is controlled at 6.7 hours. Take 10g of biochar (flaky, particle size 20-25mm) and add it to the biochar filling layer in the anaerobic digestion device, seal the anaerobic digestion device, and run the anaerobic digestion device for 10 days. Gradually reduce the amount of ethanol added in the wastewater, according to the COD ratio of ethanol to wastewater from 4:1 to 3:1, 2:1, until the wastewater does not contain etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com