Red glaze slurry as well as preparation method and application thereof

A technology of red glaze and glaze powder, applied in the field of ceramics, can solve problems such as difficulty in meeting product individualization, artistic decorative life and environmental protection, wear resistance, stain resistance, corrosion resistance, life span, environmental protection gap, and difficulty in realization. , to achieve the effect of pure and bright color, improve life quality and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

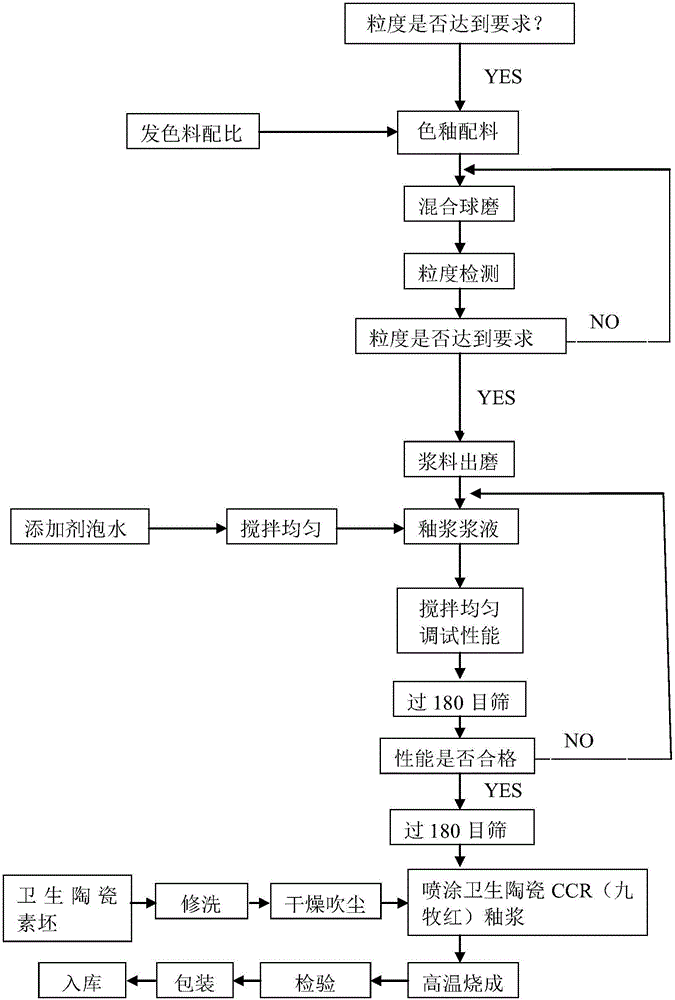

[0031] refer to figure 1 , a sanitary ceramic product, such as a toilet, its preparation method comprising:

[0032] a) Prepare sanitary ceramic green body.

[0033] The raw material of the green body is composed of the following raw materials in weight percentage: SiO 2 62~64%, Al 2 o 3 22~23%, CaO 0~0.8%, MgO 0~0.7%, K 2 O 2.5~3.5%, Na 2 O 0.3~0.5%, Fe 2 o 3 +TiO 2 1-1.5%, and the remaining auxiliary raw materials are 1-2%. The remaining auxiliary raw materials include at least one of soda ash for ceramics, water glass and dolomite.

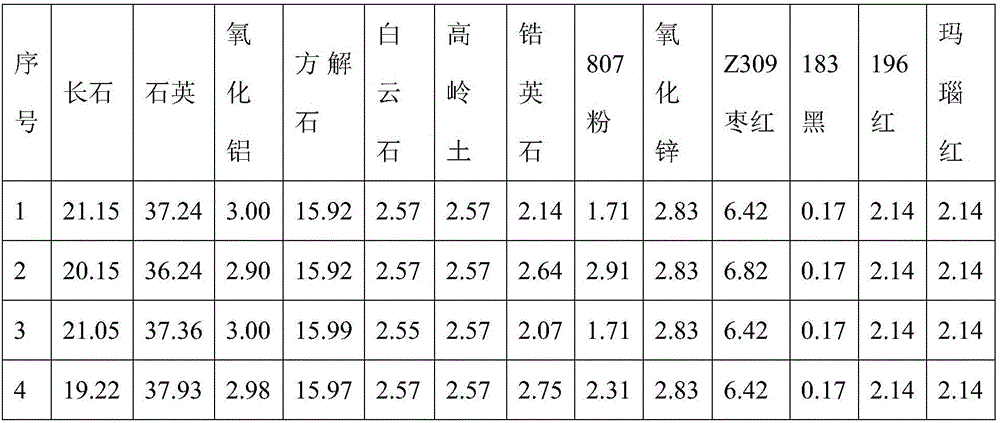

[0034] Referring to Table 1, the mass percentage composition of green body raw materials in preferred embodiments is listed.

[0035] Table 1

[0036] components SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

K 2 o

CaO Na 2 o

MgO Burn out Example 1 63.41 22.27 0.71 0.66 3.01 0.75 0.34 0.61 7.9 Example 2 63.23 22.99 0.71 0.61 2.79 0.74 0.37 0.60 7.8 Example 3 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com