Shape memory resin material for 3D printing, and preparation method and application thereof

A technology of 3D printing and resin materials, applied in the direction of additive processing, rayon manufacturing, single-component polyester rayon, etc., can solve the problems of inability to shape arbitrarily, thickness, bending stiffness, lack of elastic fixation and so on. Absorb deformation performance and other issues, achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

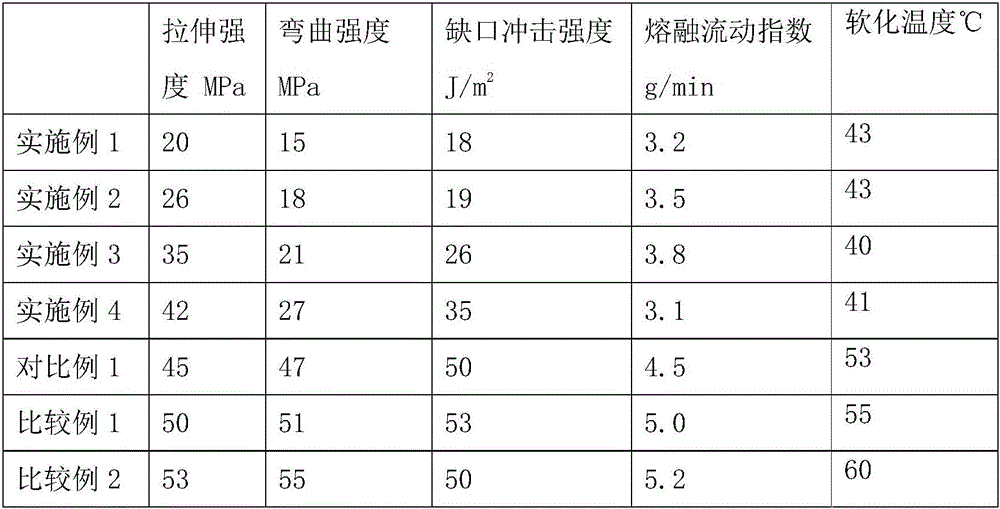

Examples

Embodiment 1

[0022] 1. Formula of polymer temperature-controlled shape memory resin material

[0023] 70 parts by weight of polycaprolactone, 5 parts by weight of polyurethane, 5 parts by weight of inorganic filler (calcium silicate), 2 parts by weight of crosslinking agent (benzoyl peroxide), surfactant (sodium laurylalanine) ) 0.5 parts by weight.

[0024] 2. Preparation method of polymer temperature-controlled shape memory resin material

[0025] Polycaprolactone, polyurethane, inorganic filler, cross-linking agent and surfactant are cross-linked and copolymerized according to the proportion of the formula, so that the molecular weight of the polymer reaches 20,000 to 50,000, and then the polymer is heated, melted, spun and formed, and water After cooling and solidifying, 3D printing monofilaments are made, wherein the drawing speed of spinning and forming is 30-90 rpm, the spinning temperature is 80-160°C, and the filament-out temperature is 80-130°C.

Embodiment 2

[0027] 1. Formula of polymer temperature-controlled shape memory resin material

[0028] 95 parts by weight of polycaprolactone, 5 parts by weight of polyurethane, 4.5 parts by weight of inorganic filler (talcum powder), 1.5 parts by weight of crosslinking agent (benzoyl peroxide), surfactant (sodium laurylaminopropionate) 1 part by weight.

[0029] 2. Preparation method of polymer temperature-controlled shape memory resin material

[0030] Compared with the preparation method of Example 1, only the ratio of raw materials is different.

Embodiment 3

[0032] 1. Formula of polymer temperature-controlled shape memory resin material

[0033] 80 parts by weight of polycaprolactone, 5 parts by weight of polyurethane, 5 parts by weight of inorganic filler (diatomaceous earth), 2.5 parts by weight of crosslinking agent (benzoyl peroxide), surfactant (dodecyl dimethylene sodium carbamate) 1.5 parts by weight.

[0034] 2. Preparation method of polymer temperature-controlled shape memory resin material

[0035] Compared with the preparation method of Example 1, only the ratio of raw materials is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com