Environment-friendly and corrosion-prevention coating for building and preparation method thereof

An anti-corrosion and environmentally friendly technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of the paint film being easily contaminated by stains, the paint film is not dense enough, and it is not easy to clean and wipe off. Excellent adhesion, meeting technical specifications, and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

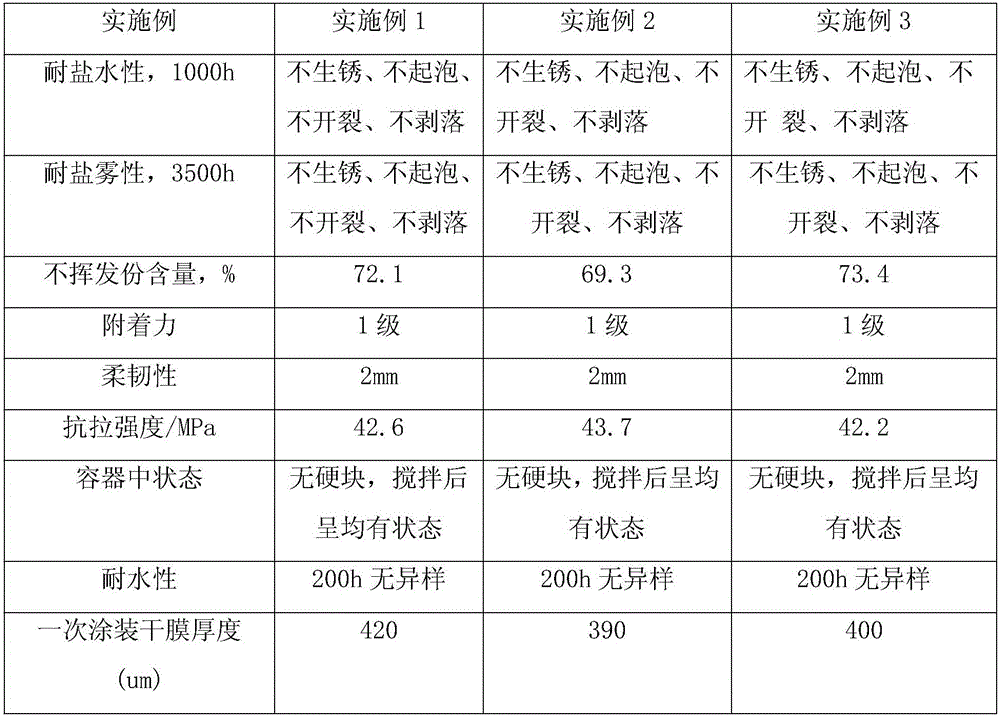

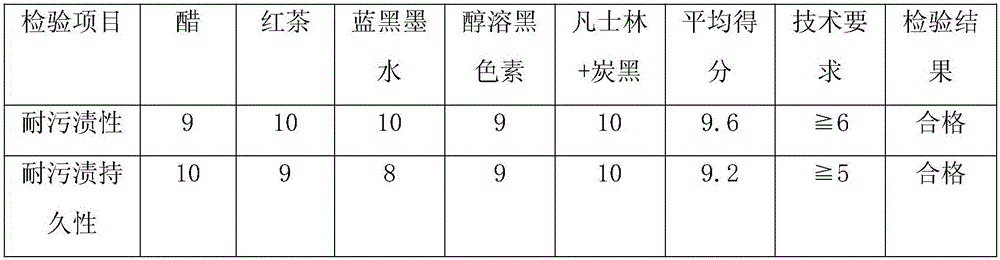

Examples

Embodiment 1

[0020] A preparation method of an environment-friendly type anti-corrosion architectural coating, comprising the steps of:

[0021] (1) 30 parts of butyl acrylate monomer, 8 parts of methacrylic acid monomer, 8 parts of styrene monomer, 25 parts of organosiloxane monomer vinyltrimethoxysilane, 3 parts of emulsifier p-octylphenol Polyoxyethylene ether, 0.2 parts of ammonium persulfate initiator and 200 parts of deionized water were added to the reaction vessel, and the temperature was raised to 70°C for in-situ polymerization for 2 hours under constant stirring. After the reaction, the system was cooled to 30°C. Then add 0.5 parts of pH adjuster to adjust the pH of the system to 8, stop stirring, and obtain a silanol-modified acrylate-styrene-acrylic emulsion;

[0022] (2) Preparation of environmentally friendly anti-corrosion architectural coatings: first add 100 parts by weight of deionized water to the reactor, heat to 35°C in a water bath, and add step (1) to the reactor un...

Embodiment 2

[0024] A preparation method of an environment-friendly type anti-corrosion architectural coating, comprising the steps of:

[0025] (1) 50 parts of butyl acrylate monomer, 12 parts of methacrylic acid monomer, 12 parts of styrene monomer, 40 parts of organosiloxane monomer vinyl triethoxysilane, 10 parts of emulsifier p-octyl Phenol polyoxyethylene ether, 0.4 parts of ammonium persulfate initiator and 400 parts of deionized water were added to the reaction vessel, and the temperature was raised to 90°C for in-situ polymerization for 4 hours under constant stirring. After the reaction, the system was cooled to 50°C , then add 1 part of pH adjuster to adjust the pH of the system to 9, stop stirring, and obtain a silanol-modified acrylate-styrene-acrylic emulsion;

[0026] (2) Preparation of environment-friendly anti-corrosion architectural coatings: first add 300 parts by weight of deionized water to the reactor, heat to 45°C in a water bath, and add step (1) to the reactor unde...

Embodiment 3

[0028] A preparation method of an environment-friendly type anti-corrosion architectural coating, comprising the steps of:

[0029] (1) 35 parts of butyl acrylate monomer, 15 parts of methacrylic acid monomer, 10 parts of styrene monomer, 50 parts of organosiloxane monomer allyl trimethoxysilane, 6 parts of emulsifier p-octyl Phenol polyoxyethylene ether, 0.3 parts of ammonium persulfate initiator and 300 parts of deionized water were added to the reaction vessel, and the temperature was raised to 80°C for in-situ polymerization for 3 hours under constant stirring. After the reaction, the system was cooled to 40°C , then add 1 part of pH adjuster to adjust the pH of the system to 8.5, stop stirring, and obtain a silanol-modified acrylate-styrene-acrylic emulsion;

[0030](2) Preparation of environment-friendly anti-corrosion architectural coatings: first add 200 parts by weight of deionized water to the reactor, heat to 40°C in a water bath, and add step (1) to the reactor und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com