Fullerene-carbon nanotube lubricating additive and preparation of fullerene-carbon nanotube lubricating additive

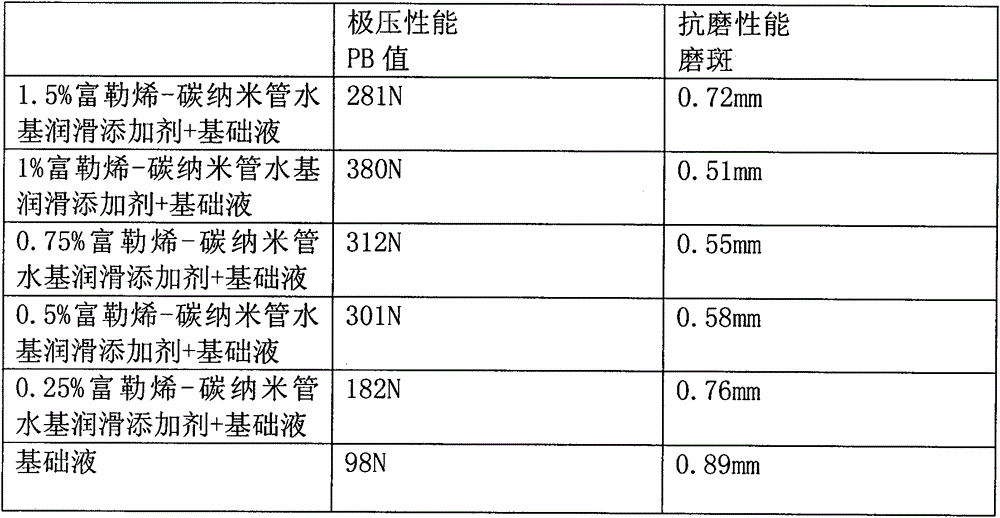

A technology of lubricating additives and carbon nanotubes, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor lubricating performance, poor stability, high cost, etc., achieve good lubricating performance, not easy to settle, and improve wear reduction and anti-wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of fullerene-carbon nanotube water-based lubricating additive in this embodiment is carried out according to the following steps:

[0017] 1. Preparation of fullerene modified by water-soluble polymer: add fullerene to toluene according to the volume ratio of the mass of fullerene to toluene at 0.1-2g: 1000mL, ultrasonically disperse for 20-90min, and then add water-soluble Unsaturated monomer and azobisisobutyronitrile, the mass ratio of fullerene to water-soluble unsaturated monomer is 1:10-200, the mass ratio of water-soluble unsaturated monomer to azobisisobutyronitrile is 1 : (0.001 ~ 0.01), stirring under nitrogen atmosphere for 10 ~ 90min, under nitrogen protection at 65 ~ 85 ℃ constant temperature stirring reaction for 10 ~ 72h, cooled to 25 ℃, to obtain a solution, and then drop by 1 ~ 12 drops / s Accelerate the solution dropwise into diethyl ether, the volume ratio of diethyl ether to toluene is 1-12:1, centrifu...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the fullerene described in step one is fullerene C 60 or fullerene C 70 . Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the water-soluble unsaturated monomer described in Step 1 is methacrylic acid, acrylamide, acrylic acid, etc. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rough surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com