Natural high-emulsibility grease powder and preparation method thereof

A technology of oil body and powder, which is applied in the field of natural high emulsifying oil body powder and its preparation, can solve the problems of unclear oil body yield and complicated process, achieve good emulsification stability and oxidation resistance, increase yield, The effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1, preparation natural high emulsifiability oil body powder

[0073] Follow the steps below to prepare natural high emulsifying oil body powder:

[0074] (1) Crushing: mechanically crush the raw corn germ until the particle size is reduced to below 15 mesh.

[0075] (2) Alkaline extraction: the maize germ crushed in step (1) is mixed with water at a mass ratio of 1:18, and the pH of the mixed material is adjusted to 10 with sodium hydroxide. Heat the material to 65°C, and stir at a constant temperature of 250 rpm for 35 minutes.

[0076] (3) Refining: put the mixed material obtained in the above step (2) into the refining system, and refine at room temperature for 45 seconds, and the fineness after refining is 50 mesh.

[0077] (4) Secondary leaching: heat the mixed slurry after refining in step (3) to 85° C., and extract at a constant temperature of 250 rpm for 35 minutes.

[0078] (5) Filtration: filter the mixed slurry obtained in the secondary extracti...

Embodiment 2

[0084] Embodiment 2, preparation natural high emulsifiability oil body powder

[0085] Follow the steps below to prepare natural high emulsifying oil body powder:

[0086] (1) Crushing: mechanically crush the raw corn germ until the particle size is reduced to below 15 mesh.

[0087] (2) Alkaline extraction: the maize germ crushed in step (1) is mixed with water at a mass ratio of 1:18, and the pH of the mixed material is adjusted to 10 with sodium hydroxide. Heat the material to 65°C, and stir at a constant temperature of 250 rpm for 35 minutes.

[0088] (3) Refining: put the mixed material obtained in the above step (2) into the refining system, and refine at room temperature for 45 seconds, and the fineness after refining is 50 mesh.

[0089] (4) Secondary leaching: heat the mixed slurry after refining in step (3) to 85° C., and extract at a constant temperature of 250 rpm for 35 minutes.

[0090] (5) Filtration: filter the mixed slurry obtained in the secondary extracti...

Embodiment 3

[0096] Embodiment 3, grease body powder performance test

[0097] (1) storage performance

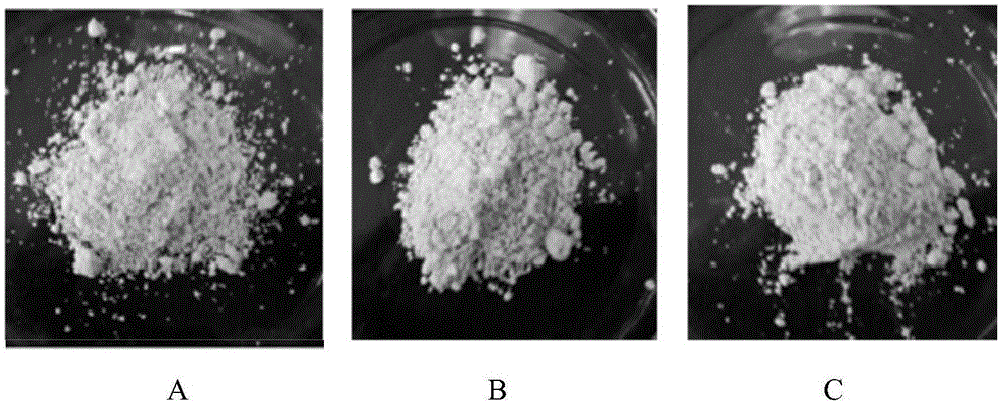

[0098] Such as figure 1 As shown, the oil powder (A) directly prepared by centrifugation in Examples 1 and 2 turns yellow in color after being stored for 2 months, and there is obvious oil phenomenon. This is caused by the broken fat body, indicating that the directly prepared fat body powder has low storage stability at room temperature. However, the oil body products (B and C) obtained in Examples 1 and 2 still kept their original appearance well after being stored for the same period of time, and there was no obvious oil-out phenomenon. It shows that the addition of protein and homogenization enhances the stability of the natural structure of the oil body, and its powder has better storage performance at room temperature. The grease body powder prepared by the invention can be stored for 60 days at room temperature, and has good storage performance.

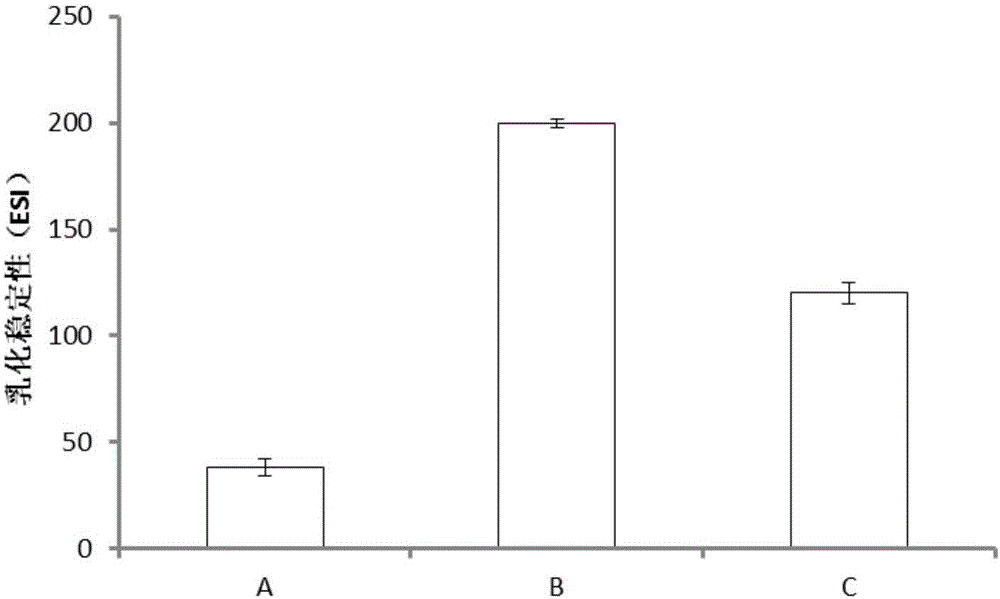

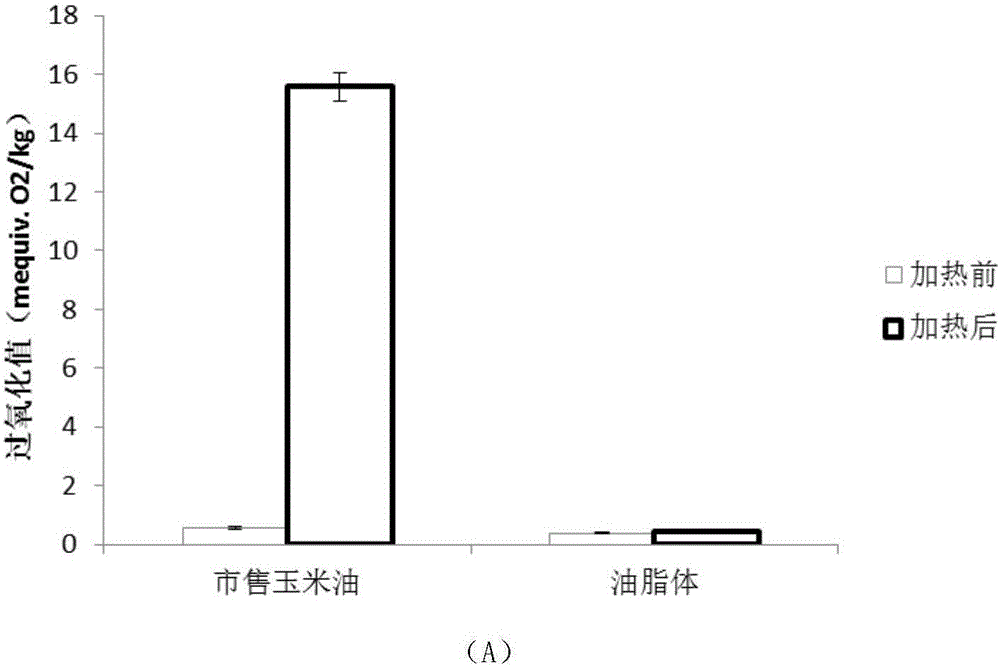

[0099] (2) Emulsion stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com