Method for in-situ preparing iron and copper dual-metal loaded carbon nano-fiber composite material

A carbon nanofiber, composite material technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of reduced specific surface area, easy loss, increased particle size, etc., to achieve broad application prospects, simple equipment requirements , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

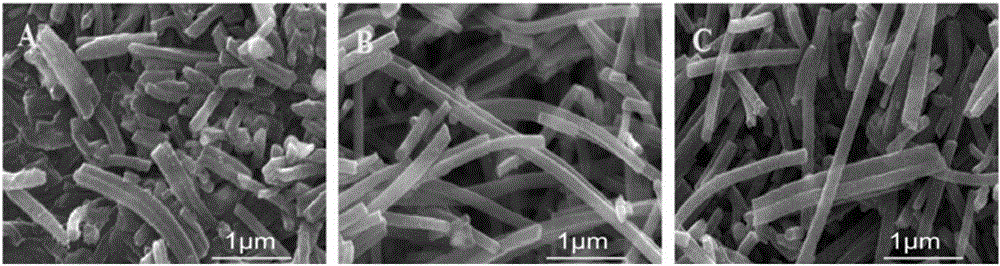

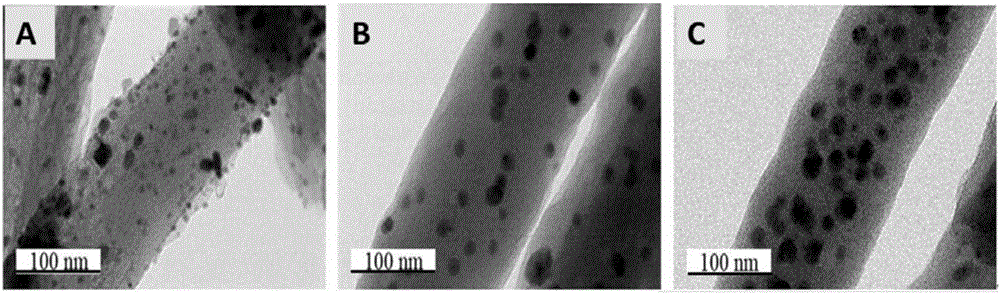

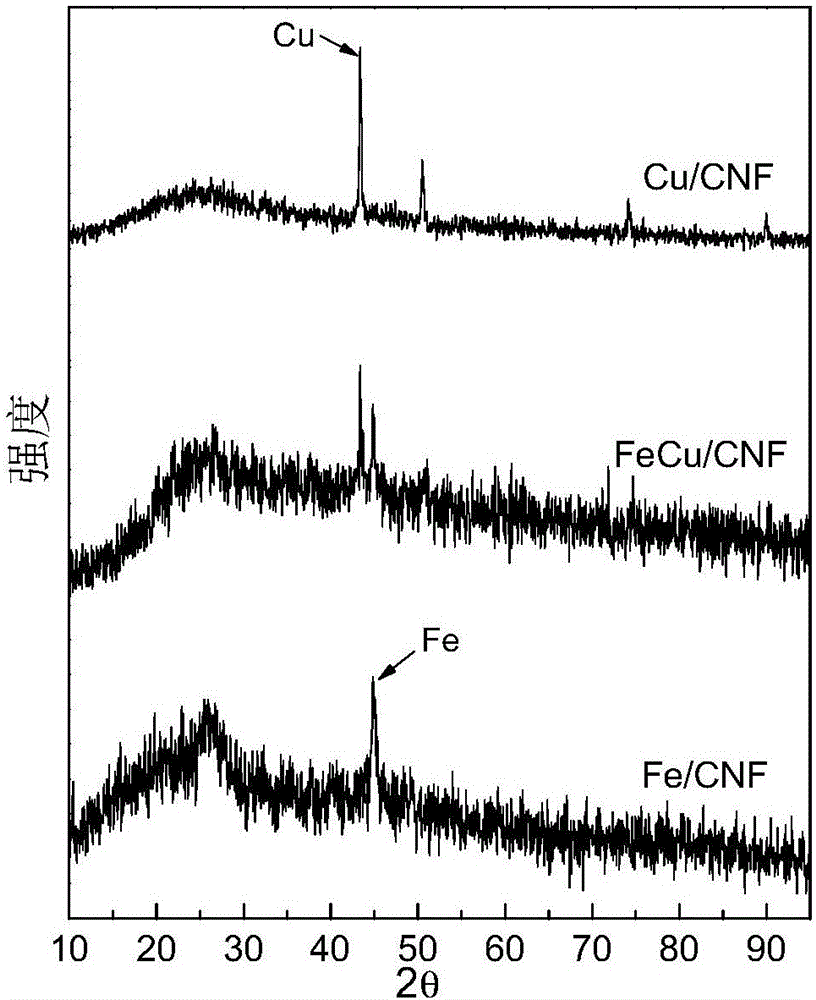

[0022] Taking the molar ratio of Fe:Cu:PAN as 1:3:0.0067 as an example, it is named as FeCu / CNF-1.

[0023] Step 1: Add 1mmol of iron acetylacetonate, 3mmol of copper acetate and 1g of polyacrylonitrile (PAN) into 20mL of N,N-dimethylformamide (DMF) solution, heat and stir at 60°C for 2h to form a homogeneous Phase solution;

[0024] Step 2: Put the solution prepared above into a syringe with a metal needle, then fix the syringe on the positive pole of the electrospinning device, and clamp the positive pole of the high-voltage power supply on the metal needle, and the pushing speed of the syringe is 1.47mL / h;

[0025] The third step: spread the aluminum film on the collecting plate of the electrospinning device, and adjust the distance between the collecting plate and the metal needle to 15cm, and the voltage to 18kV to obtain continuous and stable polyacrylonitrile fibers containing iron and copper salts;

[0026] The fourth step: collect the iron-copper-containing polyacr...

Embodiment 2

[0028] Taking the molar ratio of Fe:Cu:PAN as 2:2:0.0067 as an example, it is named FeCu / CNF-2.

[0029] Step 1: Add 2mmol of iron acetylacetonate, 2mmol of copper acetate and 1g of polyacrylonitrile (PAN) into 20mL of N,N-dimethylformamide (DMF) solution, heat and stir at 60°C for 2h to form a homogeneous Phase solution;

[0030] Step 2: Place the solution prepared above into a syringe with a metal needle, then fix the syringe on the positive pole of the electrospinning device, and clamp the positive pole of the high-voltage power supply on the metal needle, and the pushing speed of the syringe is 1.4mL / h;

[0031] The third step: spread the aluminum film on the collecting plate of the electrospinning device, and adjust the distance between the collecting plate and the metal needle to 14cm, and the voltage to 18kV to obtain continuous and stable polyacrylonitrile fibers containing iron and copper salts;

[0032] The fourth step: Collect the iron-copper-containing polyacryl...

Embodiment 3

[0034] Taking the molar ratio of Fe:Cu:PAN as 3:1:0.0067 as an example, it is named FeCu / CNF-3.

[0035] Step 1: Add 3mmol of iron acetylacetonate, 1mmol of copper acetate and 1g of polyacrylonitrile (PAN) into 20mL of N,N-dimethylformamide (DMF) solution, heat and stir at 60°C for 4h to form a homogeneous Phase solution;

[0036] Step 2: Place the above-prepared solution in a syringe with a metal needle, then fix the syringe on the positive pole of the electrospinning device, and clamp the positive pole of the high-voltage power supply on the metal needle, and the pushing speed of the syringe is 1.5mL / h;

[0037] The third step: spread the aluminum film on the collecting plate of the electrospinning device, and adjust the distance between the collecting plate and the metal needle to 16cm, and the voltage to 16kV to obtain continuous and stable polyacrylonitrile fibers containing iron and copper salts;

[0038] The fourth step: Collect the iron-copper-containing polyacrylon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com