A kind of red fluorescent powder excited by electron beam and preparation method thereof

A red phosphor and electron beam technology, applied in the field of red phosphor, can solve the problems affecting cathode emission capability and device life, luminous intensity and efficiency reduction, FED cathode pollution, etc. The effect of good luminous consistency and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

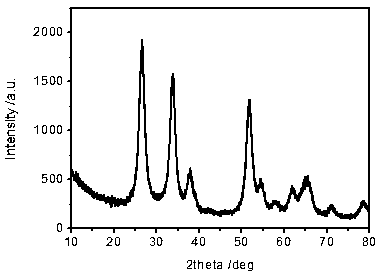

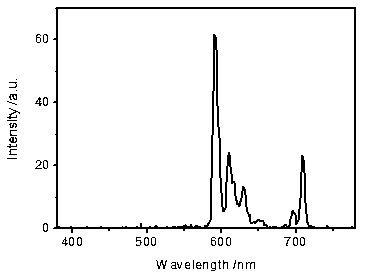

Image

Examples

Embodiment 1

[0031] According to the chemical composition formula: (Sn 0.78 Sb 0.20 Eu 0.02 )O 2 , respectively weighed 0.078molSnCl 4 ·5H 2 O, 0.020mol SbCl 3 , 0.002mol EuCl 3 ·6H 2 O, prepare a clear and transparent mixed salt solution A in vessel 1, and adjust the cation concentration to 0.4mol / L, adjust the pH of the mixed salt solution A to 1.5 with hydrochloric acid, heat to 85°C, and keep warm. Add 500ml of deionized water into vessel 2, adjust the pH of the water to 7.2 with concentrated ammonia water, heat to 85°C, and keep warm. The mixed salt solution A in vessel 1 was dropped into vessel 2 at a rate of 120ml / min. During the reaction, the temperature was controlled and stirring was continued, and the pH value of the emulsion was controlled to 7.2 by concentrated ammonia water. After the reaction was completed, the stirring was continued for half an hour and left to stand for 24 hours. Use deionized water at 50°C with a pH value of 7.2 adjusted with ammonia water as the...

Embodiment 2

[0034] According to the chemical composition formula: (Sn 0.86 Sb 0.06 Eu 0.08 )O 2 , respectively weighed 0.086mol SnCl 4 ·5H 2 O, 0.006mol SbCl 3 , 0.008mol EuCl 3 ·6H 2 O, prepare a clear and transparent mixed salt solution A in vessel 1, and adjust the cation concentration to 3.5mol / L. Use nitric acid to adjust the pH value of the mixed salt solution A to 0.2, and heat it to 50°C and keep it warm. Add 50ml of deionized water into vessel 2, adjust the pH of the water to 9.5 with potassium hydroxide solution, heat to 50°C, and keep warm. The mixed salt solution A in vessel 1 was dropped into vessel 2 at a rate of 1 ml / min. During the reaction, the temperature was controlled and stirring was continued, and the pH value of the emulsion was controlled to 9.5 by potassium hydroxide solution. After the reaction was completed, the stirring was continued for half an hour and left to stand for 24 hours. Use deionized water at 50°C with a pH value of 9.0 adjusted with ammoni...

Embodiment 3

[0036] According to the chemical composition formula: (Sn 0.84 Al 0.10 Eu 0.06 )O 2 , respectively weighed 0.086mol SnCl 4 ·5H 2 O, 0.010mol Al(NO 3 ) 3 9H 2 O, 0.006mol EuCl 3 ·6H 2O, prepare a clear and transparent mixed salt solution A in vessel 1, and adjust the cation concentration to 0.8mol / L, adjust the pH value of the mixed salt solution A to 0.5 with nitric acid, heat to 75°C, and keep warm. Add 50ml of deionized water into vessel 2, adjust the pH value of the water to 8.5 with concentrated ammonia water, heat to 50°C, and keep warm. Drop the mixed salt solution A in vessel 1 into vessel 2 at a rate of 10ml / min. During the reaction, control the temperature and keep stirring, and use concentrated ammonia water to control the pH of the emulsion to 8.5. After the reaction was completed, the stirring was continued for half an hour and left to stand for 24 hours. Use deionized water at 50°C with a pH value of 8.5 adjusted with ammonia water as the cleaning solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com