Octadecyl modified foam nickel adsorbent and application thereof

A technology of octadecyl and nickel foam, applied in other chemical processes, preparation of test samples, alkali metal oxides/hydroxides, etc., to achieve good stability, fast separation process, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of octadecyl-modified nickel foam adsorbent includes the following steps:

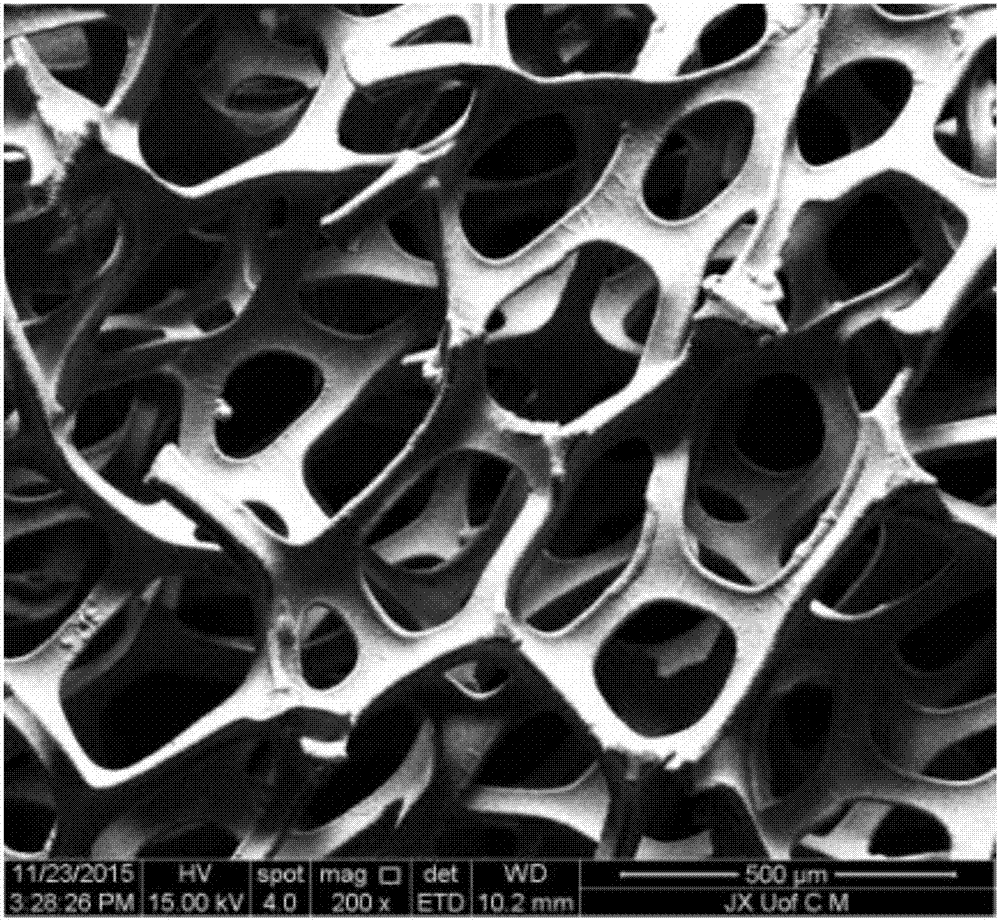

[0041] 1) Cut the foamed nickel into 1×1cm with scissors 2 In flakes, soak in acetone for 20 minutes to remove dirt, then wash with 2M HCl solution, ultrasonically treat for 30 minutes to remove the NiO layer on the surface, and finally wash with deionized water and ethanol, and dry to obtain pretreated foamed nickel for use;

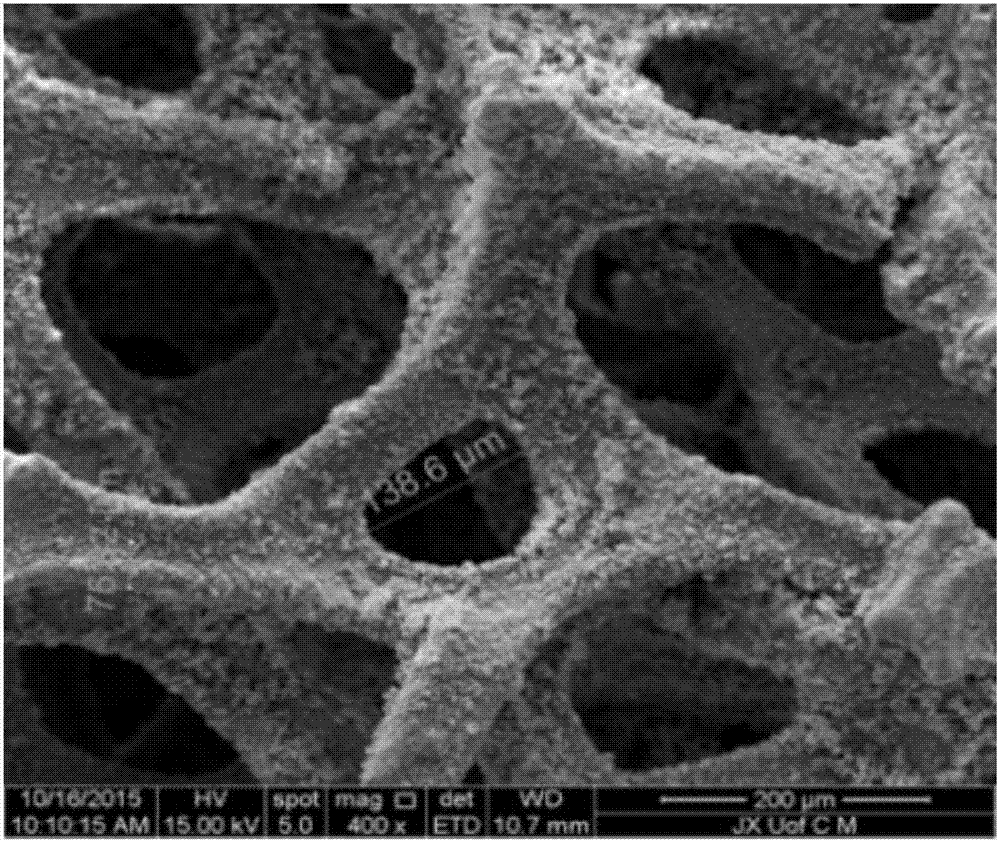

[0042] 2) Take 400 mg of pretreated nickel foam (10 pieces of NF), disperse it in a mixture of 100 mL of isopropanol and 8 mL of ultrapure water, sonicate for 15 minutes, then add 10 mL of ammonia and 8 mL of TEOS, and stir for 12 hours at 45°C. The prepared product was washed with water and ethanol, and dried in vacuum at 60°C for 12 hours. In this way, a layer of porous silica gel was wrapped around the pretreated nickel foam to obtain silicon-coated nickel foam (ie NF-SiO 2 );

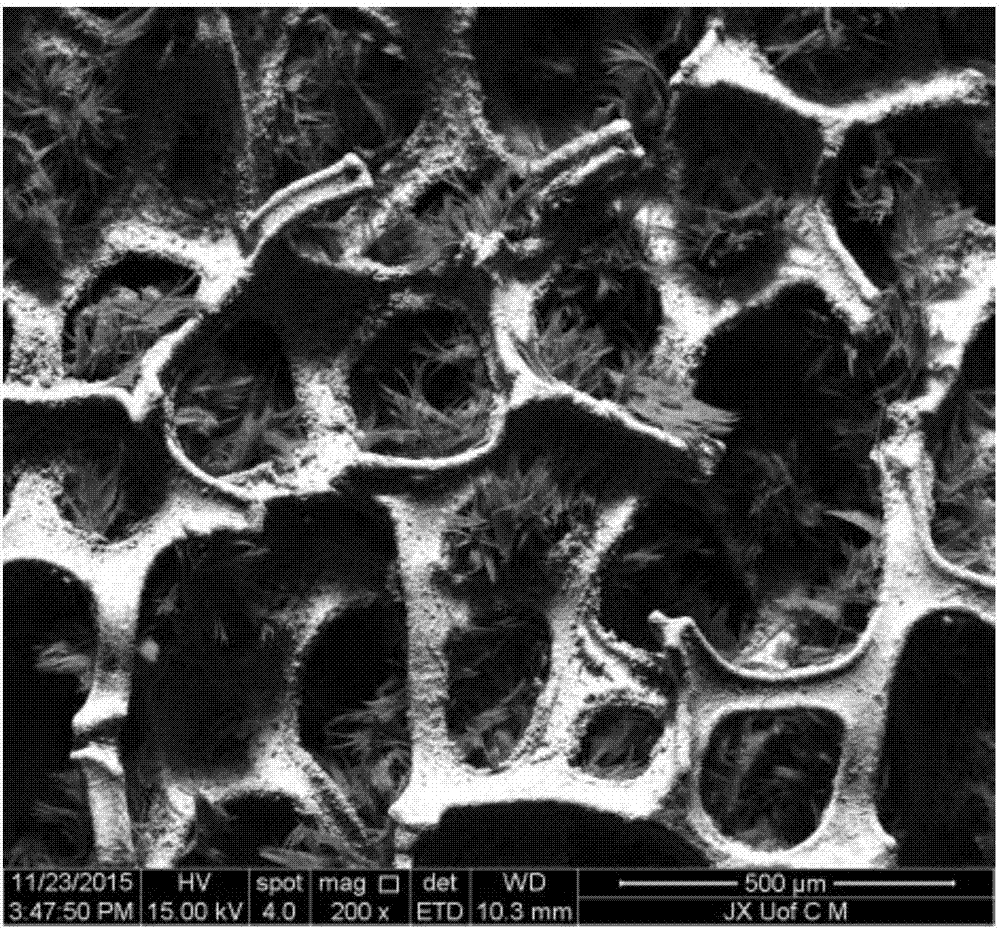

[0043] 3) Put the silicon-coated nickel foam (NF-SiO 2 ) And C 18 -The isoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com