A screening method for plastic flotation foaming agent

A screening method and technology for foaming agents, which are used in flotation, plastic recycling, analysis of materials, etc., can solve the problem of lack of selectivity and pertinence of plastics to be flotated, inability to establish a database for screening foaming agents, unfavorable resource sharing and long-term development. Development and other issues, to achieve the effect of high screening efficiency and accuracy, small screening workload, and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

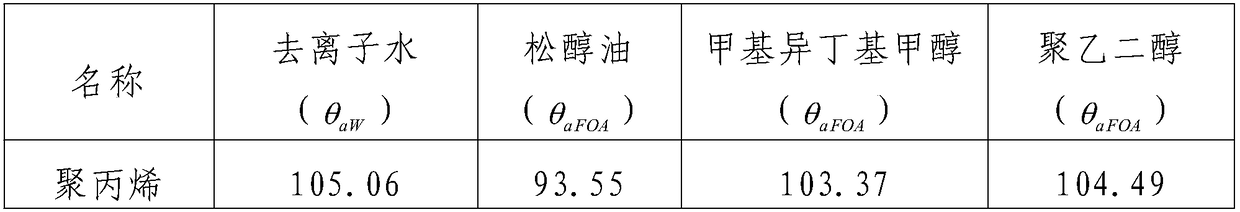

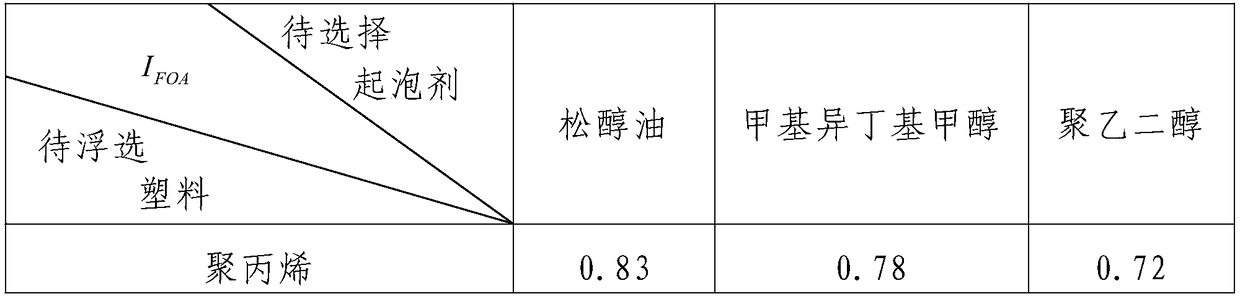

[0032] In the present embodiment, the plastic to be flotation is polypropylene, and the best foaming agent is selected from terpineol oil, methyl isobutyl carbinol, polyethylene glycol and tea saponin foaming agent, specifically comprising the following steps:

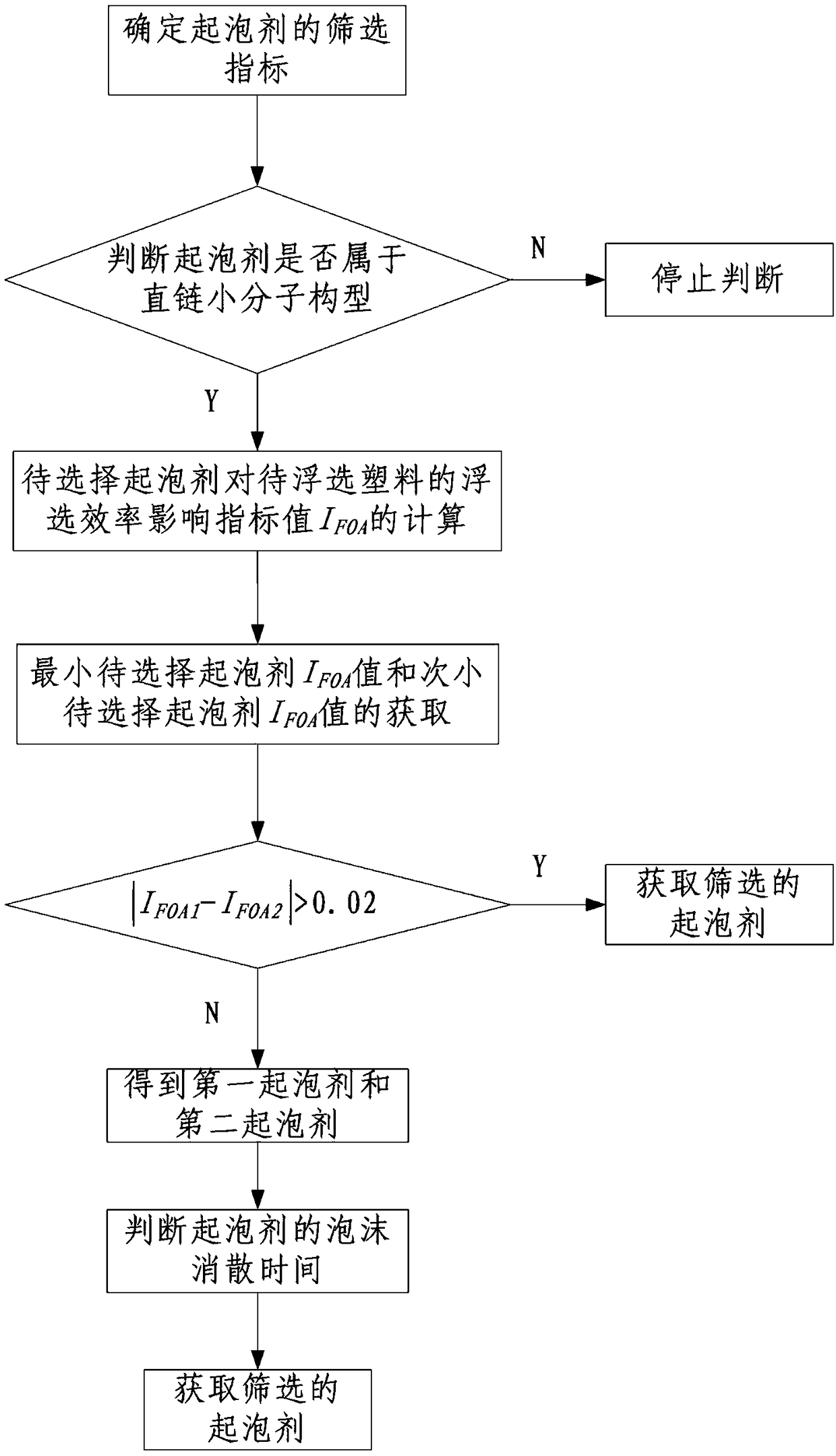

[0033] Step 1, determine the screening index of foaming agent: determine the screening index of foaming agent, the screening index of foaming agent comprises the linear small molecule structure of foaming agent, foaming agent I FOA value and the foam dissipation time of the blowing agent;

[0034] In the present embodiment, determine three indexes of blowing agent to comprise the linear small molecular structure of blowing agent, blowing agent I FOA value and blowing agent for t DIS Reasonable screening of the third index, high screening efficiency and accuracy, greatly narrows the search range of foaming agents, obtains the best foaming agent suitable for plastics to be flotation, avoids unnecessary flotation experim...

Embodiment 2

[0057] In this embodiment, the plastic to be flotation is polystyrene butadiene copolymer, and the best foaming agent is selected from terpineol oil, methyl isobutyl carbinol, polyethylene glycol and tea saponin foaming agent agent, specifically including the following steps:

[0058] Step 1, determine the screening index of the foaming agent: according to the plastic components to be flotation, determine the screening index of the foaming agent, wherein, the screening index of the foaming agent includes the linear small molecular structure of the foaming agent, the foaming agent I FOA value and blowing agent for t DIS value;

[0059] Step 2, judging whether the foaming agent belongs to the straight-chain small molecule configuration: judging whether terpineol oil, methyl isobutyl carbinol, polyethylene glycol and tea saponin belong to the straight-chain small molecule configuration, terpineol oil, methyl Isobutyl carbinol and Polyethylene Glycol belong to straight-chain small...

Embodiment 3

[0086] In this example, the difference from Example 1 is that the plastic to be flotation is an acrylonitrile-butadiene-styrene copolymer. The concentration of foaming agent solution in step 301 is 8mg / L, and the surface tension of foaming agent solution (concentration is 8mg / L) is as shown in table 10, and in step 302, deionized water and plastic acrylonitrile-butylene to be flotation Table 11 shows the contact angles of ethylene-styrene copolymers, foaming agent solutions and plastics acrylonitrile-butadiene-styrene copolymers to be flotation. Foaming agent I to be selected when the plastic to be flotation is acrylonitrile-butadiene-styrene copolymer FOA The values are shown in Table 12.

[0087] The surface tension of table 10 foaming agent solution (concentration is 8mg / L)

[0088] Foaming agent to be selected

terpineol oil

methyl isobutyl carbinol

σ FOA

71.62

55.92

51.83

[0089] Table 11 Contact angle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com