Ammonia-containing wastewater recycling system and desulfurization and denitrification dedusting system

A technology of desulfurization and denitrification and waste water circulation, applied in the direction of ammonia compounds, ammonium nitrate fertilizer, ammonium sulfate, etc., to achieve the effect of improving dust removal rate, desulfurization and denitrification effect, and resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

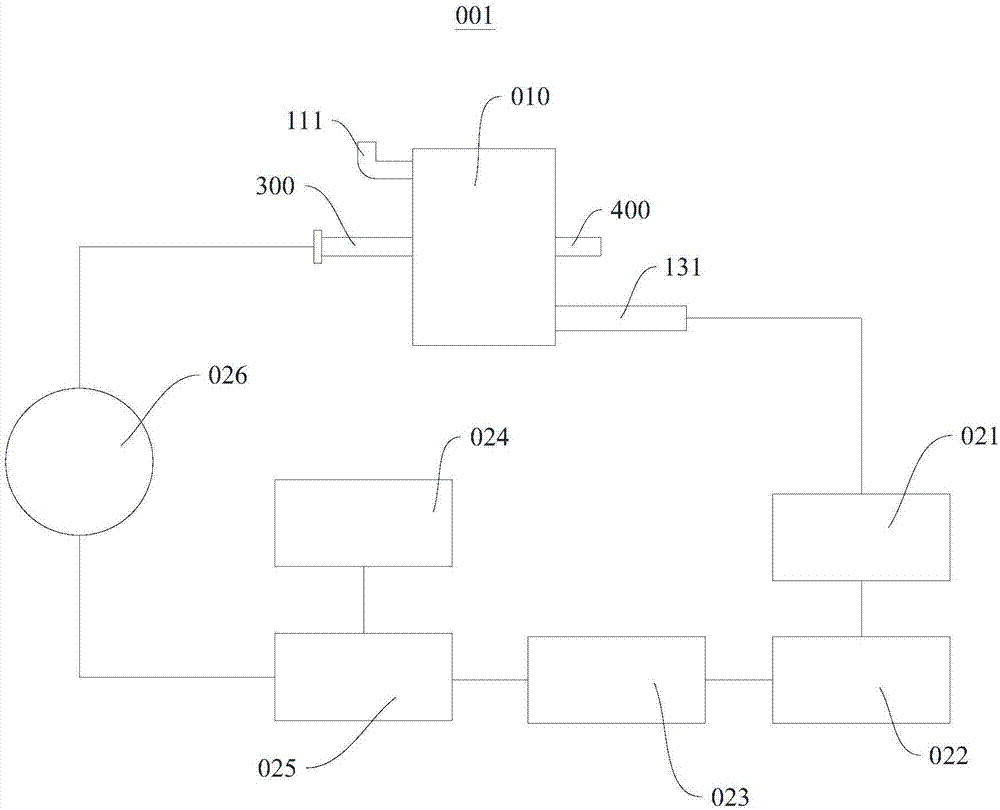

[0034] This embodiment provides a recycling system 020 for ammonia-containing wastewater, please refer to figure 1 , this ammonia-containing wastewater recycling system 020 includes a sedimentation tank 021, a dehydration device 022, an evaporation crystallization device 023, a liquid ammonia replenisher 024 and a liquid recovery tank 025;

[0035] The sedimentation tank 021 is connected to the dehydration equipment 022, wherein the sedimentation tank 021 accepts the desulfurization and denitrification wastewater generated after the desulfurization and denitrification dust collector 010 treats the waste gas, and performs primary precipitation on the desulfurization and denitrification wastewater to form the primary filtrate and the first mud, and the primary filtrate enters the dehydration equipment 022 Dehydration is carried out to generate secondary filtrate and second mud, wherein the second mud mainly includes the dust accumulated in the desulfurization and denitrification ...

Embodiment 2

[0040] This embodiment provides a desulfurization, denitrification and dust removal system 001, please refer to figure 1 , this desulfurization, denitrification and dust removal system 001 includes the ammonia-containing wastewater recycling system 020 and the desulfurization, denitration and dust removal device 010 in the first embodiment;

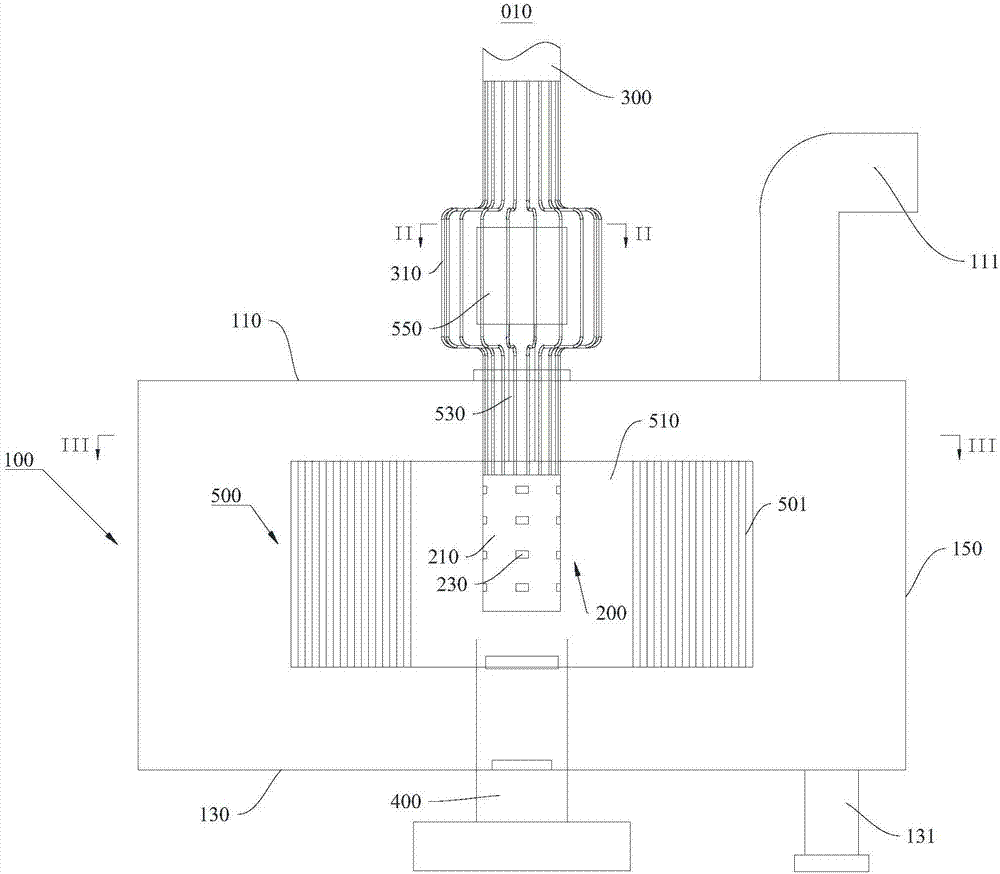

[0041] The desulfurization and denitrification dust remover 010 includes a housing 100 , a spraying device 200 , an ammonia water delivery pipe 300 and an exhaust gas pipe 400 .

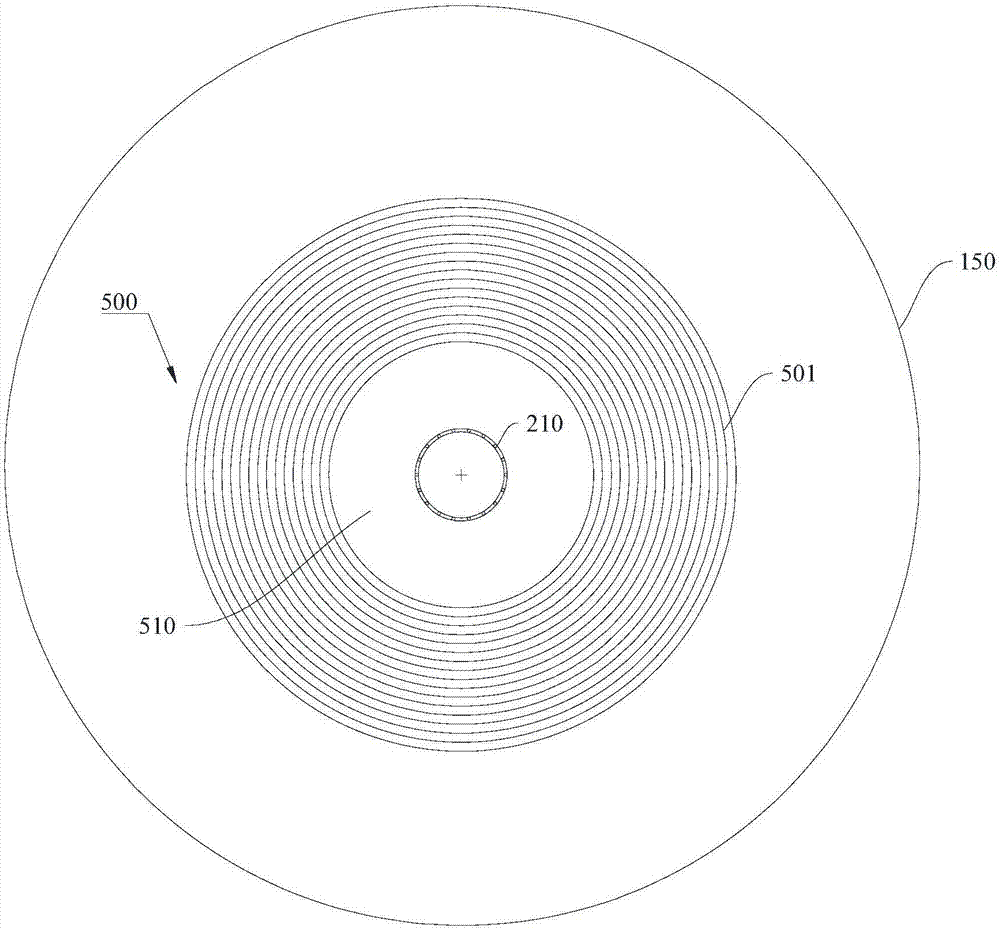

[0042] see figure 2 and image 3 , the casing 100 is a cylindrical sealed casing, and the casing 100 includes a first surface 110 , a second surface 130 , and a side surface 150 that are oppositely arranged. The ammonia water delivery pipe 300 passes through the center of the first surface 110 and is sealingly connected with the casing 100 , through which the ammonia water delivery pipe 300 can deliver ammonia water into the casing 100 . The end of the ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com