A kind of preparation method of high-quality polyester polyol

A polyester polyol, high-quality technology, applied in the field of preparation of high-quality polyester polyol, can solve the problems of product scrap, gel, influence, etc., and achieve the effect of stable moisture content and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

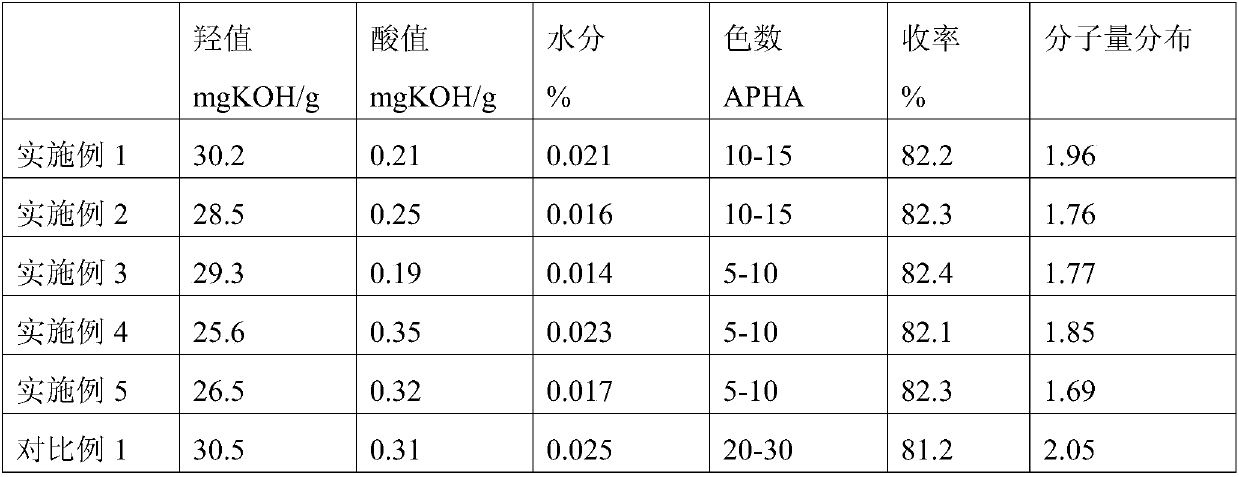

Examples

preparation example Construction

[0011] The preparation method of high-quality polyester polyol of the present invention, it comprises the following steps: (a) add dibasic carboxylic acid and dibasic alcohol in the reactor with rectification column, gradually heat up to 180~200 ℃ under inert gas atmosphere ℃ for esterification and dehydration reaction, and control the temperature at the top of the rectification tower to be 90-110 ℃; (b) add catalyst to the reaction kettle, raise the temperature to 220-250 ℃ at a speed of 5-10 ℃ / 30min, and The polycondensation reaction can be carried out under reduced pressure; the reduced pressure condition is to increase from 0.01MPa to 0.1MPa at a gradient speed of 0.005 to 0.015MPa and keep it for 0.5 to 1 hour after each increase. The quality of the catalyst is as follows: 0.005% to 0.05% of the total mass of dibasic carboxylic acid and glycol. On the one hand, precise control of the temperature at the top of the distillation column can prevent the loss of small molecule ...

Embodiment 1

[0015] The present embodiment provides a kind of preparation method of high-quality polyester polyol, and it comprises the following steps:

[0016] (a) add 146.0kg adipic acid (10.0mol) and 713.0kg ethylene glycol (11.0mol) in the reactor with rectifying tower, heat reaction mixture under nitrogen protection, and control the temperature at the top of rectifying tower The temperature is 95℃~100℃, the specific heating process is: raise the temperature to 130-135℃ at a speed of 5℃ / 30min, keep it for 1.5 hours, continue to heat up to 150-160℃, keep it for 0.5 hours, then raise the temperature to 180℃, keep it for 0.5 hours Hours; continue to heat up to 220-230 ° C constant temperature 2-3 hours.

[0017] (b) Add 0.027kg of catalyst (tetrabutyl titanate) to the reactor with carrier gas, and then keep it at 220°C for 4 hours; carry out polycondensation reaction under reduced pressure, specifically: keep at 0.01Mpa for 0.4h, 0.02Mpa for 0.4h, 0.03Mpa for 0.4h, 0.04Mpa for 0.4h, 0.0...

Embodiment 2

[0019] This example provides a method for preparing high-quality polyester polyol, the preparation process of which is basically the same as that in Example 1, except that the temperature at the top of the rectification tower is controlled at 90-95°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com