ZnFe2O4@SiO2@RGO wave absorbent and preparation process thereof

A preparation process, znfe2o4 technology, applied in other chemical processes, magnetic/electric field shielding, electrical components, etc., can solve problems such as reinforced composites, achieve great application prospects, mild preparation conditions, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

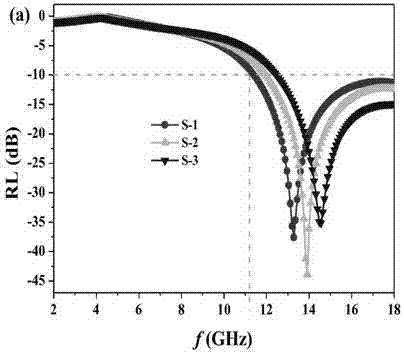

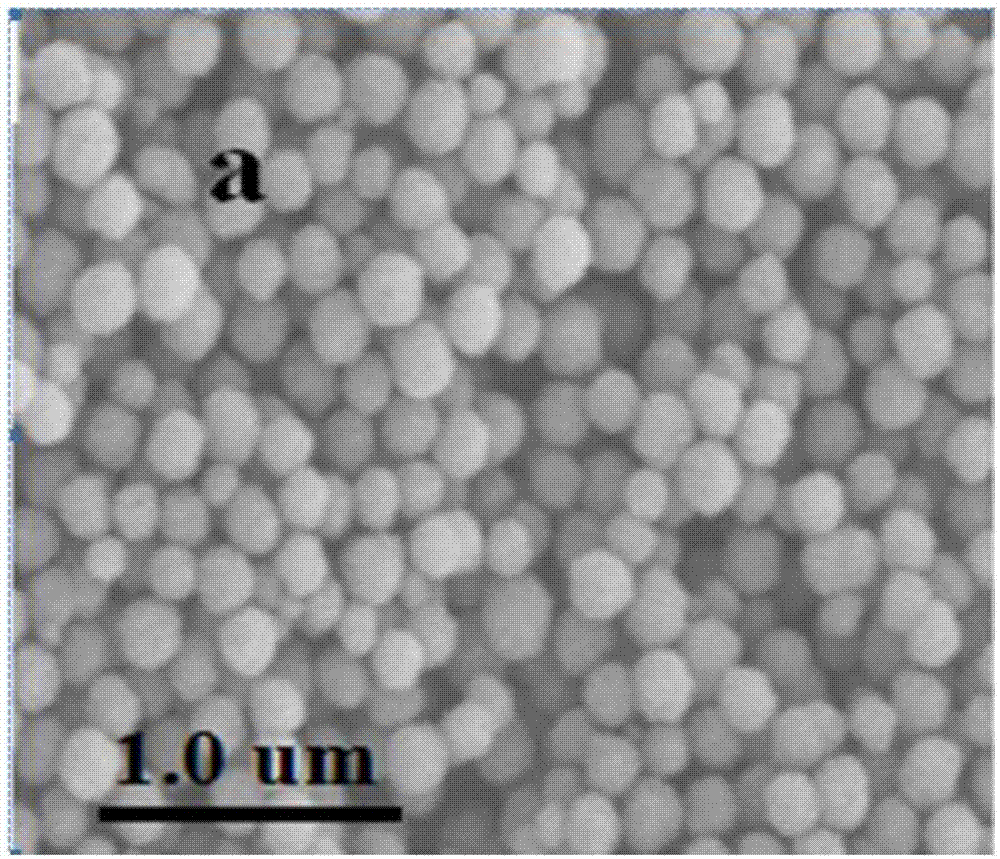

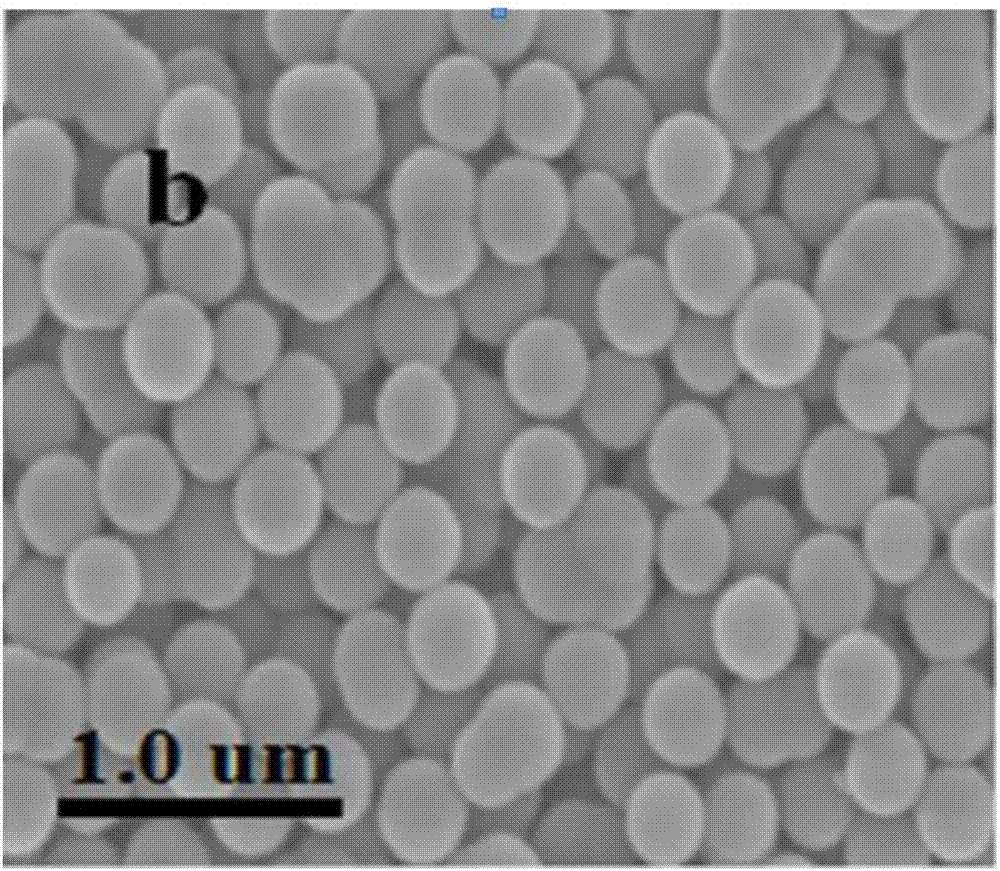

[0029] (1) Weigh 1.352g FeCl 3 ·6H 2 O and 0.341g ZnCl 2 Dissolve in 40 mL of ethylene glycol solution, then add 0.500 g of trisodium citrate and 3.600 g of anhydrous NaAc, and stir ultrasonically for 0.5 hours. The obtained yellow clear liquid was transferred into a stainless steel reaction kettle, reacted at 150° C. for 8 hours, cooled naturally to room temperature, and filtered. The solid phase was washed three times with deionized water and ethanol respectively, and the solid phase was dispersed in 50 mL of ethanol-water mixed solvent (volume ratio of deionized water and absolute ethanol was 1:1), and 1 mL of NH 3 ·H 2 O, stir evenly, and record it as mixed solution A; take another 0.4mL tetraethyl orthosilicate (TEOS) solution and disperse it in 20mL absolute ethanol, and record the obtained solution as B. The solution B was added dropwise to the mixture A using a constant pressure dropping funnel, and the mixture was continuously stirred at room temperature for 8 hou...

Embodiment 2

[0034] (1) Weigh 2.702g FeCl 3 ·6H 2 O and 0.682g ZnCl 2 Dissolve in 60 mL of ethylene glycol solution, then add 1.000 g of trisodium citrate and 7.200 g of anhydrous NaAc, and stir ultrasonically for 1 hour. Prepare mixed solution A according to the method of step (1) of Example 1 (in 100mL ethanol-water mixed solvent (deionized water and absolute ethanol volume ratio 1:1), 2mL NH 3 ·H 2 O); Another 0.4mL tetraethyl orthosilicate (TEOS) solution was dispersed in 40mL absolute ethanol, and the resulting solution was denoted as B. Prepare ZnFe by the method of the step (1) of embodiment 1 2 o 4 @SiO 2 binary complex.

[0035] (2) Weigh 0.6g expandable graphite (EG) and 6.0g KMnO 4 Place in a 500mL three-necked flask, stir and mix evenly, slowly add 100mL of concentrated H 2 SO 4 and 15 mL concentrated H 3 PO 4 The mixed solution, prepare suspension A (RGO content is about 2mg / mL) by the method for embodiment 1 step (2); 0.4g ZnFe 2 o 4 @SiO 2 The complex was diss...

Embodiment 3

[0039] (1) Weigh 4.055g FeCl 3 ·6H 2 O and 1.023g ZnCl 2 Dissolve in 90mL ethylene glycol solution, then add 1.500g trisodium citrate and 10.800g anhydrous NaAc, and stir ultrasonically for 1 hour. Prepare mixed solution A according to the method of step (1) of Example 1 (in 150mL ethanol-water mixed solvent (deionized water and absolute ethanol volume ratio 1:1), 3mL NH 3 ·H 2 O); Another 0.4mL tetraethyl orthosilicate (TEOS) solution was dispersed in 40mL absolute ethanol, and the resulting solution was denoted as B. Prepare ZnFe by the method of the step (1) of embodiment 1 2 o 4 @SiO 2 binary complex.

[0040] (2) Weigh 0.9g expandable graphite (EG) and 9.0g KMnO 4 Place in a 500mL three-necked flask, stir and mix evenly, slowly add 150mL concentrated H 2 SO 4 and 20 mL concentrated H 3 PO 4 The mixed solution, prepare suspension A (RGO content is about 3mg / mL) by the method for embodiment 1 step (2); The ZnFe of 0.6g 2 o 4 @SiO 2 The complex was dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com