Integral sisal hemp degumming process

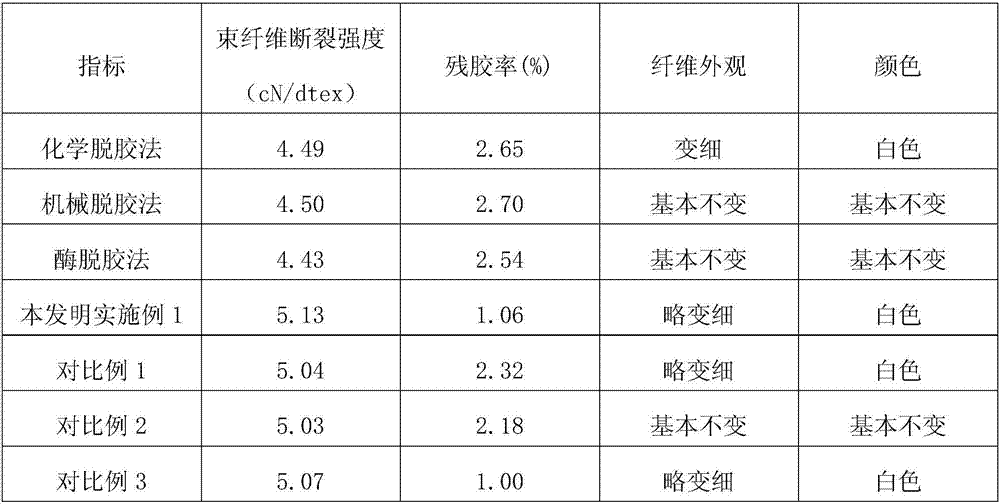

A sisal and degumming technology, applied in the field of textile processing, can solve the problems of chemical reagents polluting the environment, high residual glue rate, and low breaking strength, and achieve the effects of using less chemical reagents, increasing the degumming rate, and reducing the residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of joint degumming process of sisal, is characterized in that, comprises the following steps:

[0035] (1) Pretreatment: Flatten the harvested fresh sisal leaves and put them into a rolling machine to repeatedly and completely roll them until the sisal leaves do not come out of water, then soak them in 5% acetic acid solution at room temperature for 1.5 hours, and finally soak them After the sisal leaves are washed with clear water to PH=6.5, the cleaned sisal leaves are obtained;

[0036] (2) High-pressure alkaline cooking: take the cleaned sisal leaves and add a NaOH solution with a concentration of 8g / L, then cook for 3 hours under an environment with a steam pressure of 0.8Mpa and a temperature of 150°C, wherein the cleaned sisal leaves and NaOH solution The mass ratio is 1:4;

[0037] (3) Impurity removal: the sisal leaves after cooking are taken out and beaten and rubbed, then washed with water to remove impurities such as pectin attached to the sisal leav...

Embodiment 2

[0042] A kind of joint degumming process of sisal, is characterized in that, comprises the following steps:

[0043] (1) Pretreatment: Flatten the harvested fresh sisal leaves and put them into a rolling machine to repeatedly and completely roll them until the sisal leaves do not come out of water, then soak them in 6% acetic acid solution at room temperature for 1.7 hours, and finally soak them The final sisal leaves are washed with clear water to PH=6.6 to obtain cleaned sisal leaves;

[0044] (2) High-pressure alkaline cooking: take the cleaned sisal leaves and add a NaOH solution with a concentration of 10g / L, and then place the steam pressure at 1.0Mpa and cook for 2.8 hours under an environment of 140°C, wherein the cleaned sisal leaves and NaOH The mass ratio of the solution is 1:5;

[0045] (3) Impurity removal: the sisal leaves after cooking are taken out and beaten and rubbed, then washed with water to remove impurities such as pectin attached to the sisal leaves, a...

Embodiment 3

[0050] A kind of joint degumming process of sisal, is characterized in that, comprises the following steps:

[0051] (1) Pretreatment: Flatten the harvested fresh sisal leaves and put them into a rolling machine to repeatedly and completely roll them until the sisal leaves do not come out of water, then soak them in 7% acetic acid solution at room temperature for 2 hours, and finally soak them After the sisal leaves are washed with clear water to PH=6.7, the cleaned sisal leaves are obtained;

[0052] (2) High-pressure alkaline cooking: take the cleaned sisal leaves and add NaOH solution with a concentration of 12g / L, and then place them in an environment with a steam pressure of 1.2Mpa and a temperature of 130°C for 3 hours, wherein the cleaned sisal leaves and NaOH The mass ratio of the solution is 1:6;

[0053] (3) Impurity removal: the sisal leaves after cooking are taken out and beaten and rubbed, then washed with water to remove impurities such as pectin attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com