Bio-base high-elastic moisture-absorbing easily-dyed long carbon chain polyamide 5X fiber and preparation method thereof

A polyamide, long carbon chain dibasic acid technology, applied in the field of polyamide materials, can solve the problems of not meeting the use standard, low elastic recovery rate, high moisture regain, and achieve reduced emissions, high elastic recovery rate, and large fracture the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The invention relates to a bio-based high-elastic, moisture-absorbing and easy-to-dye long carbon chain polyamide 5X fiber and a preparation method thereof.

[0065]

[0066] The production raw material of polyamide 5X fiber of the present invention contains at least 1,5-pentanediamine and long carbon chain dibasic acid; or, take 1,5-pentamethylenediamine and long carbon chain dibasic acid as monomer polymerization to obtain Polyamide 5X.

[0067] [1,5‐pentamethylenediamine]

[0068] 1,5-Pentylenediamine can be produced from bio-based raw materials through biological methods.

[0069] Biological methods include the production of 1,5-pentanediamine by biotransformation methods (such as fermentation and enzymatic conversion methods) using bio-based raw materials; or the production of 1,5-pentanediamine by biotransformation methods using petroleum-based raw materials; or using 1,5-Pentylenediamine is produced chemically from bio-based raw materials. Thus, pentamethyle...

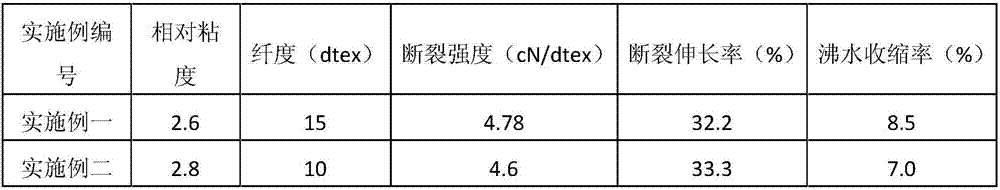

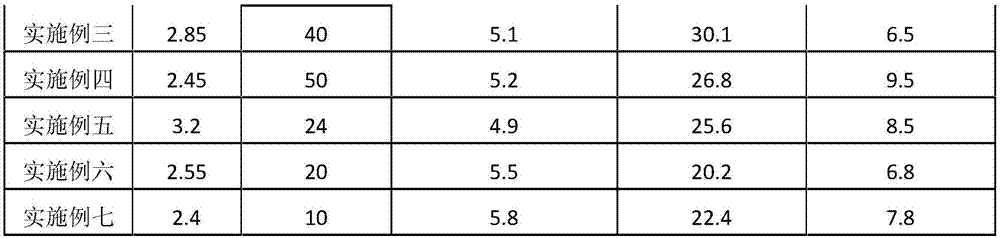

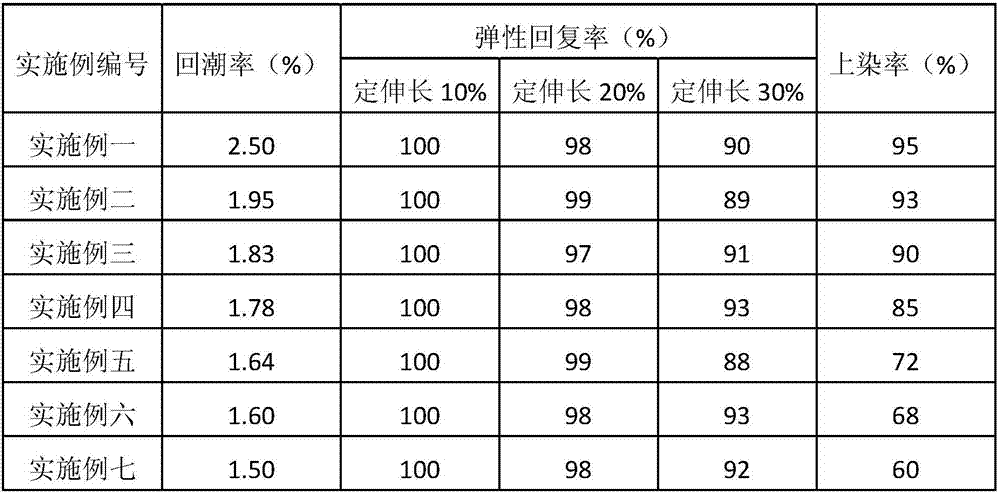

Embodiment 1

[0147] Embodiment one: polyamide 510 fiber

[0148] The present embodiment provides a kind of preparation method of polyamide 510 fiber, it comprises the steps:

[0149] (1), heating the polyamide 510 resin to a molten state to form a polyamide 510 melt;

[0150] (2), polyamide 510 melt is carried out spinning, forms spun silk;

[0151] (3) Polyamide 510 fibers are obtained after processing the as-spun silk.

[0152] Wherein, in step (1), the relative viscosity of polyamide 510 resin (in chip form) is 2.6, the water content is 300ppm, and it is prepared by biological method.

[0153] The heating in step (1) is carried out in a single-screw extruder, and the screw extruder is divided into five heating zones, the temperature of the first zone is 180°C, the temperature of the second zone is 220°C, and the temperature of the third zone is 260°C. The temperature in the fourth zone is 270°C, and the temperature in the fifth zone is 280°C.

[0154] The spinning in step (2) includ...

Embodiment 2

[0158] Embodiment two: polyamide 511 fiber

[0159] The present embodiment provides a kind of preparation method of polyamide 511 fiber, it comprises the steps:

[0160] (1), heating the polyamide 511 resin to a molten state to form a polyamide 511 melt;

[0161] (2), polyamide 511 melt is spun to form spun silk;

[0162] (3) Polyamide 511 fibers are obtained after processing the as-spun silk.

[0163] Wherein, in step (1), the relative viscosity of polyamide 511 resin (in chip form) is 2.8, the water content is 400ppm, and it is prepared by biological method.

[0164] The heating in step (1) is carried out in a single-screw extruder, and the screw extruder is divided into five zones for heating, the temperature in the first zone is 170°C, the temperature in the second zone is 240°C, and the temperature in the third zone is 260°C. The temperature in the fourth zone is 280°C, and the temperature in the fifth zone is 280°C.

[0165] The spinning in step (2) includes the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com