Metal element-doped and carbon-coated lead powder and preparation method and application thereof

A metal element, carbon coating technology, applied in electrical components, lead-acid battery electrodes, battery electrodes, etc., can solve the problem of difficulty in obtaining powder with uniform composition, affecting the beneficial effect of carbon materials, and reducing battery cycle life. , to achieve the effect of good electrochemical performance, easy large-scale industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

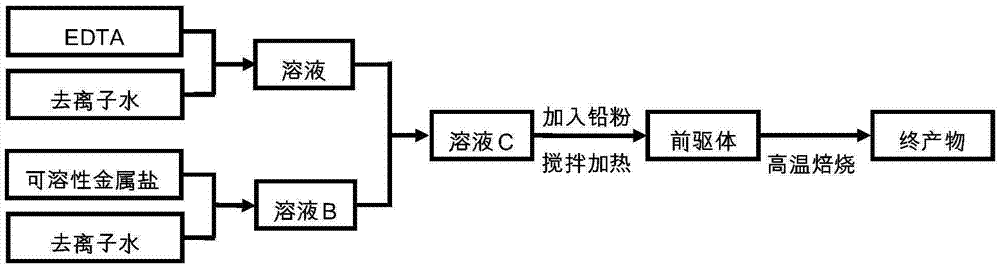

Embodiment 1

[0046] 0.2974g EDTA was dissolved in 150mL deionized water to obtain EDTA solution A. Dissolve 0.0127 g of cerium nitrate in 50 mL of deionized water to obtain aqueous solution B of cerium nitrate. Add solution B to solution A, stir for 10 min until the reaction is complete, and obtain solution C. Add 10g of lead powder into solution C and stir evenly, then place it in an electric blast drying oven and dry it at 80°C until the water is completely removed. After the dried product was ground uniformly, it was calcined at 500° C. for 8 h in nitrogen, cooled to room temperature, and ground to obtain a cerium-doped carbon-coated lead powder composite electrode material. Add 1 g of water and 0.8 g of sulfuric acid with a mass concentration of 50% to the composite electrode material while stirring to obtain the lead-carbon battery negative electrode lead paste. Scrape-coat the lead paste on the lead metal grid, cure at 40°C and 80% humidity for 30 hours; then dry at 80°C and humidi...

Embodiment 2

[0048] 0.2947g EDTA was dissolved in 150mL deionized water to obtain EDTA solution A. Dissolve 0.0075 g of lead nitrate in 50 mL of deionized water to obtain lead nitrate aqueous solution B. Add solution B to solution A, stir for 10 min until the reaction is complete, and obtain solution C. Add 10g of lead powder into solution C and stir evenly, then place it in an electric blast drying oven and dry it at 80°C until the water is completely removed. After the dried product was ground uniformly, it was calcined at 600° C. for 8 h in nitrogen, cooled to room temperature, and ground to obtain a lead-doped carbon-coated lead powder composite electrode material. Add 1 g of water and 0.8 g of sulfuric acid with a mass concentration of 50% to the composite electrode material while stirring to obtain the lead-carbon battery negative electrode lead paste. Scrape-coat the lead paste on the lead metal grid, cure at 40°C and 80% humidity for 30 hours; then dry at 80°C and humidity less t...

Embodiment 3

[0050] 0.2947g EDTA was dissolved in 150mL deionized water to obtain EDTA solution A. Dissolve 0.0136g of lanthanum nitrate in 50mL of deionized water to obtain indium nitrate aqueous solution B. Add solution B to solution A, stir for 10 min until the reaction is complete, and obtain solution C. Add 10g of lead powder into solution C and stir evenly, then place it in an electric blast drying oven and dry it at 80°C until the water is completely removed. After the dried product was ground uniformly, it was calcined at 600° C. for 8 h in nitrogen, cooled to room temperature, and ground to obtain a lanthanum-doped carbon-coated lead powder composite electrode material. Add 1 g of water and 0.8 g of sulfuric acid with a mass concentration of 50% to the composite electrode material while stirring to obtain the lead-carbon battery negative electrode lead paste. Scrape-coat the lead paste on the lead metal grid, cure at 40°C and 80% humidity for 30 hours; then dry at 80°C and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com