Bismuth vanadate composite photocatalyst jointly loaded by cuprous oxide and sliver and preparation method and application thereof

A cuprous oxide, bismuth vanadate technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of poor photo-generated electron and hole transfer and separation The ability of the bismuth vanadate material to achieve the photocatalytic effect, the degree of response is not ideal, etc., to achieve the effect of being beneficial to the contact, improving the photocatalytic ability, and improving the light absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

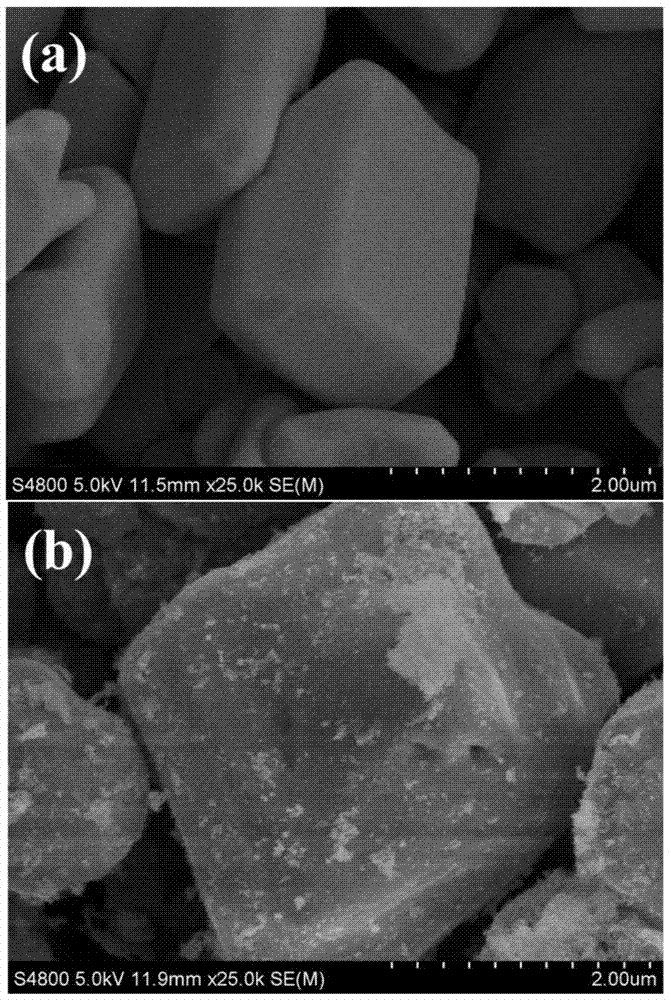

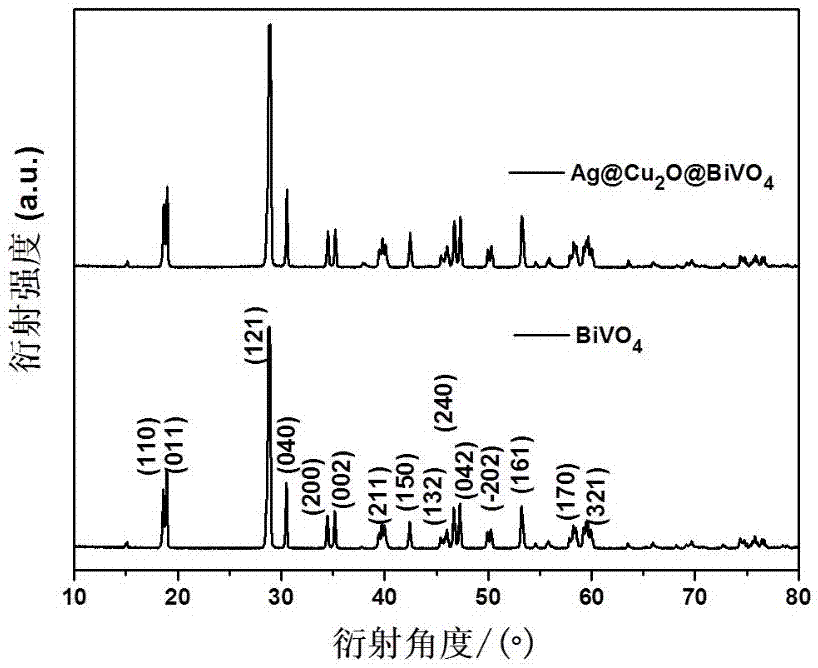

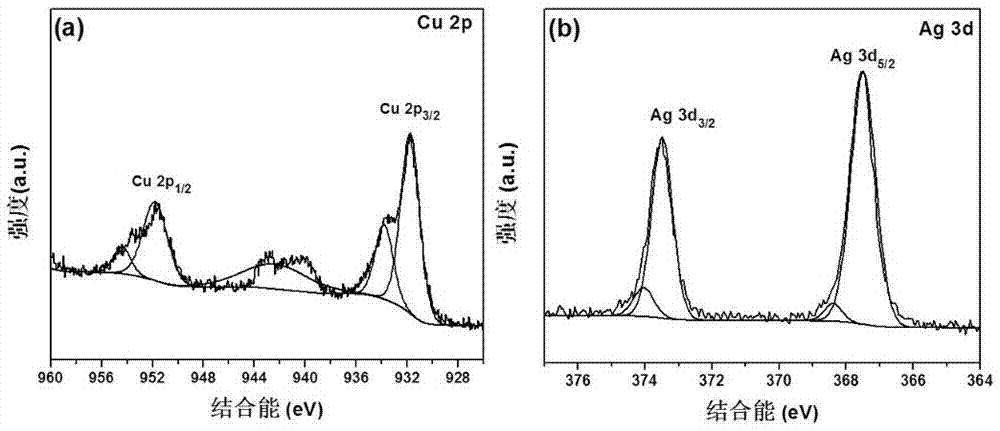

[0042] A bismuth vanadate composite photocatalyst supported by cuprous oxide and silver, the bismuth vanadate composite photocatalyst supported by cuprous oxide and silver uses bismuth vanadate particles as the carrier, and the surface of the bismuth vanadate particles is modified with cuprous oxide The particles form a cuprous oxide-supported bismuth vanadate composite material, and the surface of the cuprous oxide-supported bismuth vanadate composite material is modified with silver nanoparticles.

[0043] In this embodiment, the cuprous oxide particles grow in situ and adhere to the surface of the bismuth vanadate particles by heating reaction, wherein the mass ratio of the bismuth vanadate particles to the cuprous oxide particles is 1:0.03, and the bismuth vanadate particles are nanoparticles.

[0044] In this example, silver nanoparticles are attached to the surface of the bismuth vanadate composite material supported by cuprous oxide by photoreduction, wherein the mass r...

Embodiment 2

[0054] A bismuth vanadate composite photocatalyst supported by cuprous oxide and silver (Ag@Cu 2 O@BiVO 4 ) application in the treatment of antibiotic wastewater, comprising the following steps:

[0055] (1) Weigh 40 mg of the bismuth vanadate composite photocatalyst (Ag@Cu 2 O@BiVO 4 ), added to 100 mL of tetracycline hydrochloride wastewater with an initial concentration of 20 mg / L in a dark environment, and placed in a photocatalytic reaction device for photocatalytic reaction after adsorption for 30 minutes.

[0056](2) Using a 300W xenon lamp as the light source, the photocatalytic reaction was carried out in the visible light region for 60 minutes to complete the treatment of antibiotic wastewater.

[0057] Measure the absorbance value of the reaction solution at the wavelength of 357 nm when the illumination time is 0, 10min, 20min, 30min, 40min, 50min, and 60min, and combine the standard curve to obtain the tetracycline hydrochloride concentration C corresponding to...

Embodiment 3

[0061] Bismuth vanadate composite photocatalyst supported by cuprous oxide and silver (Ag@Cu 2 O@BiVO 4 ) application in the treatment of antibiotic wastewater, comprising the following steps:

[0062] (1) Weigh 40 mg of the bismuth vanadate composite photocatalyst (Ag@Cu 2 O@BiVO 4 ), added to 100 mL of tetracycline hydrochloride wastewater with an initial concentration of 20 mg / L in a dark environment, and placed in a photocatalytic reaction device for photocatalytic reaction after adsorption for 30 minutes.

[0063] (2) Using a 300W xenon lamp as the light source, the photocatalytic reaction was carried out in the visible light region for 60 minutes to complete the treatment of antibiotic wastewater.

[0064] The total organic carbon (TOC) in the reaction solution was measured when the light time was 0min, 15min, 30min, 45min, and 60min, so as to evaluate the ability of the prepared composite photocatalyst to completely mineralize antibiotic pollutants. The results are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com