Method for monitoring electric arc length through electric arc voltage signals

An arc voltage and signal monitoring technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems affecting the effective energy of arc heat sources, restricting the quality of welding or additive manufacturing, etc., and achieve offline detection and online monitoring, The monitoring results are intuitive and highly operable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

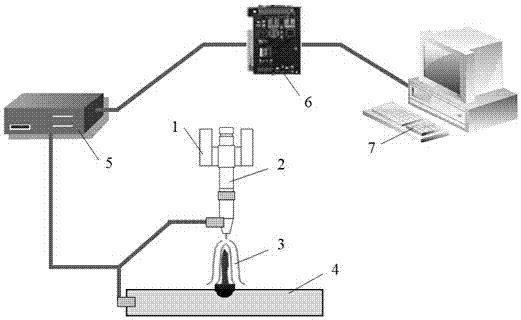

Method used

Image

Examples

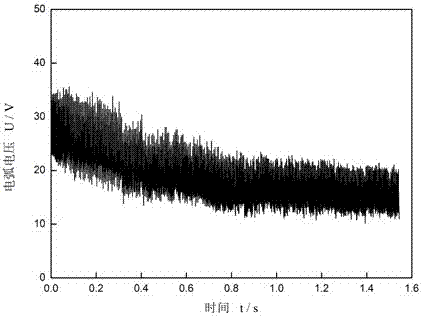

Embodiment 1

[0045] For MIG welding, a 6061 aluminum alloy plate with a thickness of 6mm is used as the substrate, and a 4043 aluminum alloy welding wire with a diameter of 1.2mm is used as the metal welding wire. The shielding gas is high-purity argon with a purity of 99.999%, and the flow rate of the shielding gas is 18L / min. First establish the mathematical model of the arc length: set the arc current output as 118A, the arc voltage output as 20.6V, the arc pulse frequency as 100Hz, and the traveling speed as 30mm / s. The aluminum alloy welding wire used is connected to the positive pole of the power supply, and the substrate is connected to the negative pole of the power supply. Install the base plate and fix it reliably horizontally, and clamp the MIG arc welding torch to the traveling mechanism of the 3D CNC work platform. Orient the MIG torch so that it is perpendicular to the plane of the substrate. Set the walking speed along the x direction to 30mm / s, the walking time to 1.55s, a...

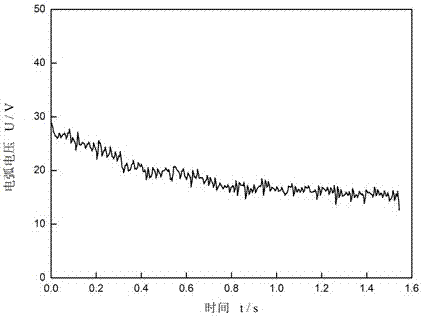

Embodiment 2

[0049] For MIG welding, a 6061 aluminum alloy plate with a thickness of 6mm is used as the substrate, and a 4043 aluminum alloy welding wire with a diameter of 1.2mm is used as the metal welding wire. The shielding gas is high-purity argon with a purity of 99.999%, and the flow rate of the shielding gas is 18L / min. First establish the mathematical model of the arc length: set the arc current output as 146A, the arc voltage output as 22.0V, the arc pulse frequency as 100Hz, and the moving speed of the traveling mechanism as 30mm / s. The aluminum alloy welding wire used is connected to the positive pole of the power supply, and the substrate is connected to the negative pole of the power supply. Install the base plate and fix it reliably horizontally, and clamp the MIG arc welding torch to the traveling mechanism of the 3D CNC work platform. Orient the MIG torch so that it is perpendicular to the plane of the substrate. Set the walking speed along the x direction to 30mm / s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com