Nitrogen and phosphorus co-doped porous carbon material and preparation method thereof

A porous carbon material and co-doping technology, applied in the field of nanomaterials, can solve the problems of unsuitable industrial applications, cumbersome and complicated process, and unfriendly environment, and achieve the effect of improving hydrophilicity, uniform pore size distribution, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

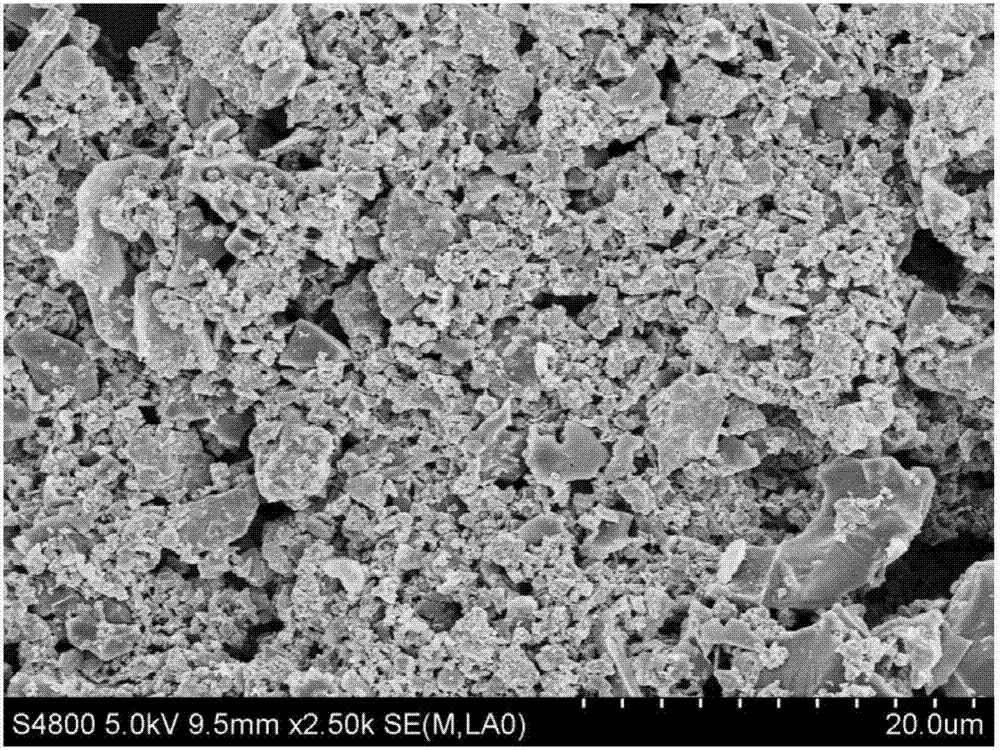

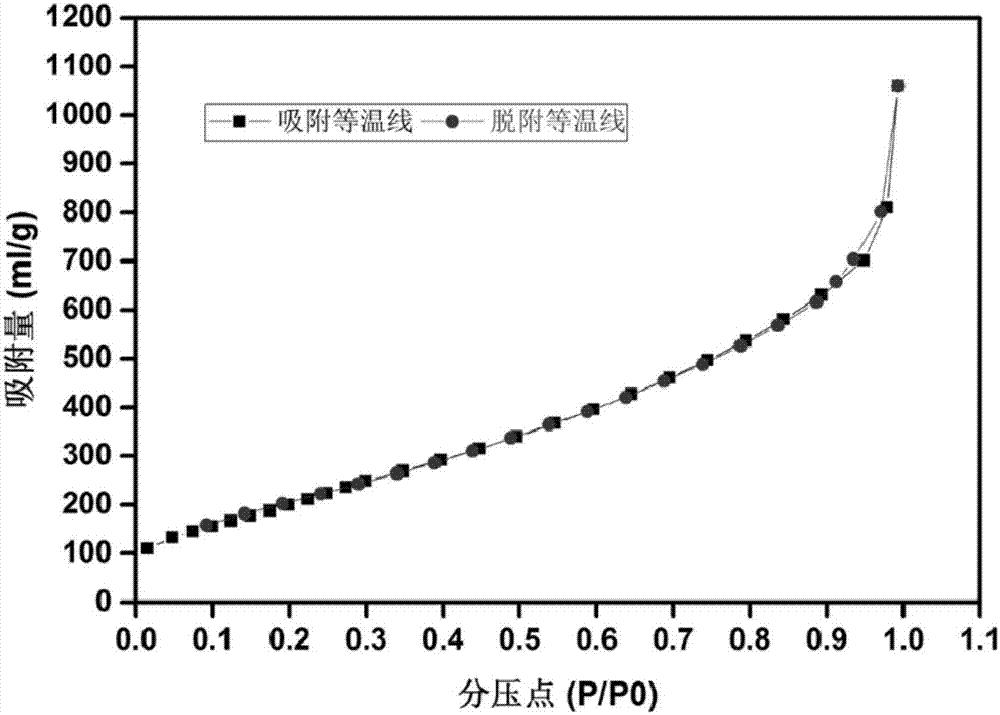

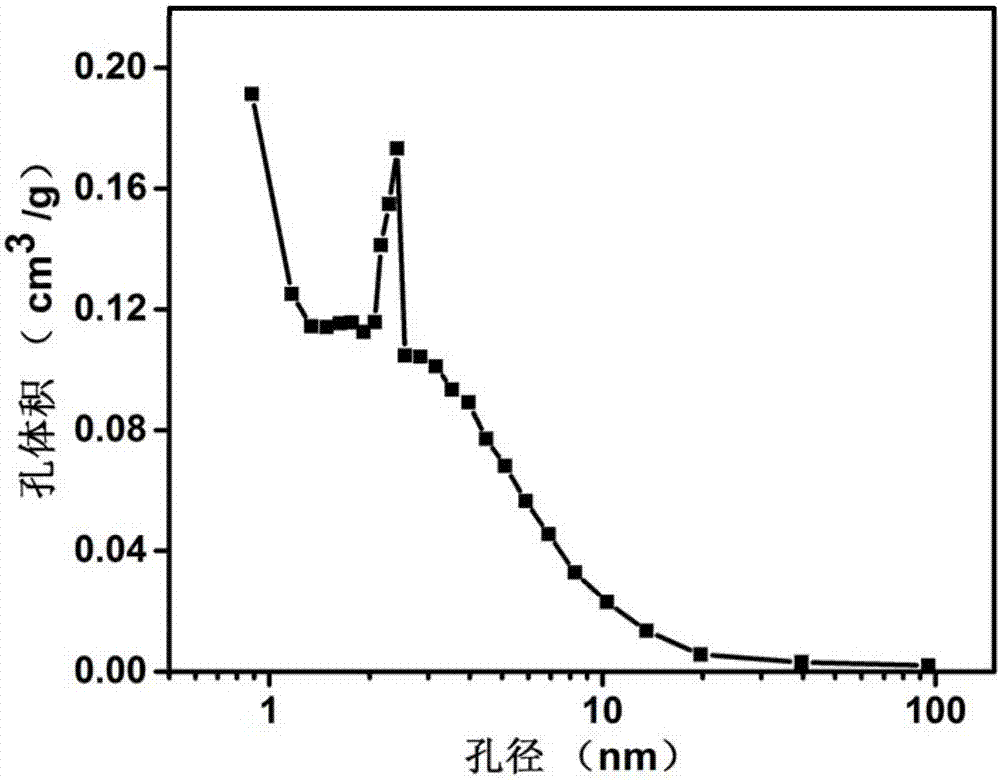

[0025] A preparation method of nitrogen and phosphorus co-doped porous carbon material, comprising the steps of: first dissolving poly-4-vinylpyridine and potassium phosphate in a 1:1 ratio (mass ratio) in 0.1mol / L dilute hydrochloric acid solution, stirring 4 hours, then vacuum distillation to evaporate the solvent to dryness, under the protection of nitrogen atmosphere, activate at 600°C for 2 hours, after natural cooling, wash in 1mol / L hydrochloric acid solution for 48 hours, then wash with deionized water to neutral pH properties, and dried to obtain nitrogen and phosphorus co-doped porous carbon materials. The specific surface area of nitrogen and phosphorus co-doped porous carbon material is 801m 2 / g, the pore size distribution is uniform, and the nitrogen and phosphorus contents are 8.2% and 7.3% respectively.

[0026] as the picture shows, figure 1 SEM of the nitrogen and phosphorus co-doped porous carbon material obtained in Example 1. figure 2 It is the nitro...

Embodiment 2

[0028] A kind of preparation method of nitrogen, phosphorus co-doped porous carbon material, comprises the following steps: first poly-4-vinylpyridine and potassium phosphate are dissolved in 0.1mol / L dilute hydrochloric acid solution by 1:3 ratio (mass ratio), stir 4 hours, then vacuum distillation to evaporate the solvent to dryness, under the protection of nitrogen atmosphere, activate at 700°C for 2 hours, after natural cooling, wash in 1mol / L hydrochloric acid solution for 48 hours, then wash with deionized water to neutral pH properties, and dried to obtain nitrogen and phosphorus co-doped porous carbon materials. The specific surface area of nitrogen and phosphorus co-doped porous carbon material is 742m 2 / g, the pore size distribution is uniform, and the nitrogen and phosphorus contents are 6.3% and 5.1%, respectively.

Embodiment 3

[0030] A preparation method of nitrogen and phosphorus co-doped porous carbon material, comprising the steps of: first dissolving poly-4-vinylpyridine and potassium phosphate in a 1:5 ratio (mass ratio) in 0.1mol / L dilute hydrochloric acid solution, stirring 4 hours, then vacuum distillation to evaporate the solvent to dryness, under the protection of nitrogen atmosphere, activate at 800°C for 2 hours, after natural cooling, wash in 1mol / L hydrochloric acid solution for 48 hours, then wash with deionized water to neutral pH properties, and dried to obtain nitrogen and phosphorus co-doped porous carbon materials. Nitrogen and phosphorus co-doped porous carbon material has a specific surface area of 701m 2 / g, the pore size distribution is uniform, and the nitrogen and phosphorus contents are 4.1% and 3.6%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com