Amorphous duplex-metal cyanide catalyst and preparation method and application thereof

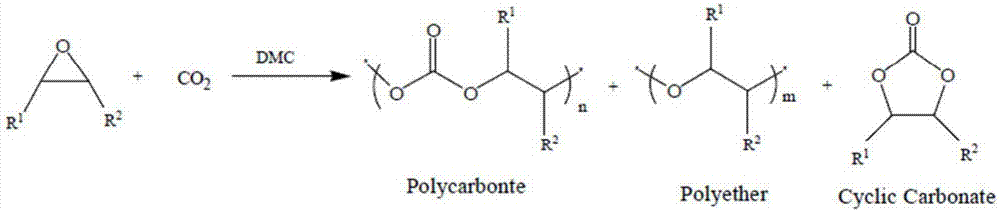

A double metal cyanide and catalyst technology, which is applied in the field of amorphous double metal cyanide catalyst and its preparation, can solve the problem that the copolymerization product cannot take into account high carbonate unit content, low cyclic carbonate content, low molecular weight distribution and the like at the same time , to achieve the effect of great practical application value and market prospect, promotion activity and catalytic activity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the DMC-1 of cyclohexane-water inverse microemulsion system

[0026] The preparation method comprises the following steps:

[0027] (1) Measure 108ml of cyclohexane and 2.16mL of water to prepare a reverse microemulsion, add 10.2mL Triton X-100 and 7.75mL of tert-butanol, and add them to a three-necked flask to prepare a microemulsion for later use.

[0028] (2) Weigh 1.36g ZnCl 2 (1×10 -2 mol) and 0.66g K 3 [Co(CN) 6 ] 2 (2×10 -3 mol) were dissolved in 2 mL of deionized water and added to the above system respectively to obtain mixed solutions A and B.

[0029] (3) Slowly add the mixed solution B to the mixed solution A under the condition of stirring at 333K, and control the dropping speed at 5-10 seconds / drop. React in the ultrasonic field for 2h.

[0030](4) then the above-mentioned mixed solution was centrifuged at a rotating speed of 10000r / min for 10 minutes to separate the precipitate, and the solid powder obtained carried out Soxhlet extra...

Embodiment 2

[0032] The catalyst preparation method is basically the same as in Example 1, except that the cyclohexane in Example 1 is replaced by heptane in equal volume, and the prepared catalyst is marked as DMC-2.

Embodiment 3

[0034] The preparation method of the catalyst is basically the same as in Example 1, except that the equivalent volume of cyclohexane in Example 1 is replaced by benzene, and the prepared catalyst is marked as DMC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com