Insulation powder coating, and preparation method and painting method thereof, and lithium battery metal shell coated with insulation powder coating

A technology of insulating powder and metal casing, which is applied in powder coating, battery case/cover, secondary battery, etc. It can solve problems such as leakage or short circuit, air bubbles and gaps, and high cost, and achieve improved reliability, excellent insulation, and good The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

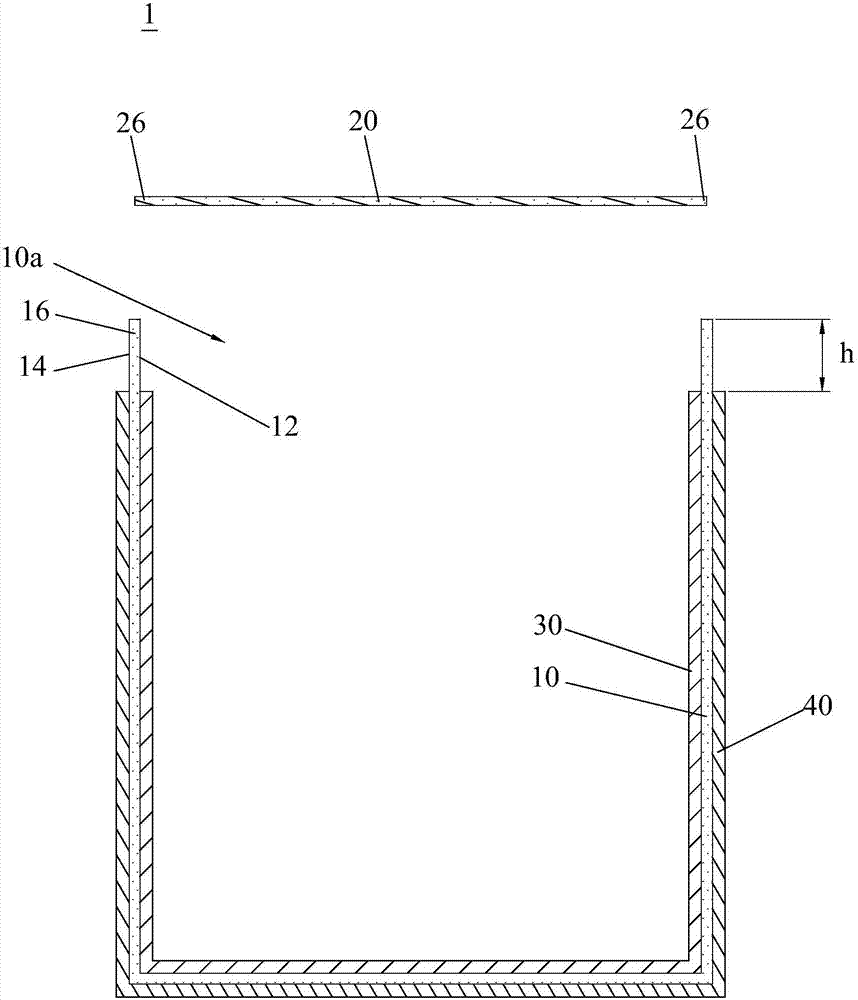

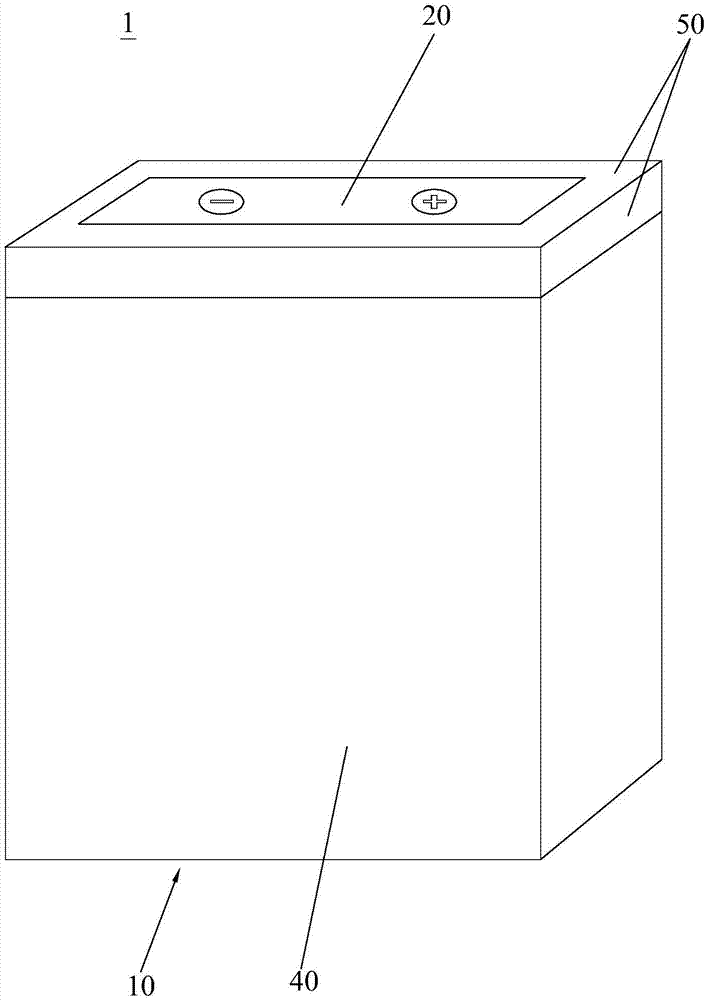

Image

Examples

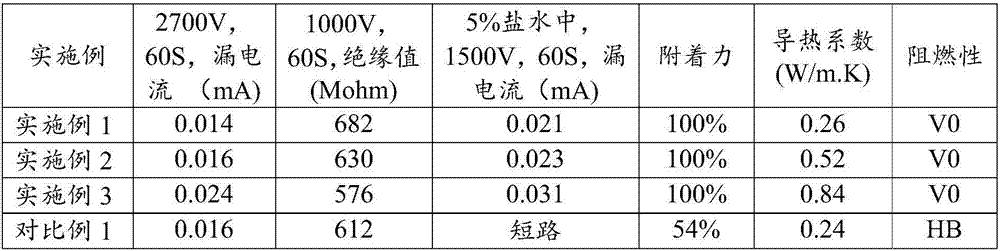

Embodiment 1~3

[0044] raw material Example 1 Example 2 Example 3 DER664 80 DER667 40 EPON 1009 20 40 80 EPCN 704 10 10 TTA3150 10 XFT-1 20 40 XFT-3 40 Octaaminopropyl cage silsesquioxane 2 2 1 3-Aminopropyltriethoxysilane 1 1 1 Melamine 6 Dicyandiamide 4 2 Aluminum hydroxide 40 40 40 AJICURE PN-40 1.5 1.5 100A 1 Barium sulfate 40 40 Aluminum oxide 80 120 Phthalocyanine blue 1 1 1 Thixotropic agent 1 1 Defoamer 1 1 1

[0045] The insulating powder coatings of the above-mentioned embodiments are prepared by the following process:

[0046] 1) Pre-mixing: Add solid epoxy resin, silicone resin, latent curing agent, flame retardant, accelerator, filler, pigment, leveling agent, etc. into the pre-mixer according to the ratio in the above table, and stir 10-30 minutes, such as 10, 12, 15, 18, 20, 22, 25, 27, 29 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com