Infrared laser driven graphene-based hydrogel motor and preparation method thereof

An infrared laser and graphene-based technology, applied in the field of infrared laser-driven hydrogel motors and its preparation, can solve problems such as unfavorable practical applications, and achieve good application prospects, low equipment dependence, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

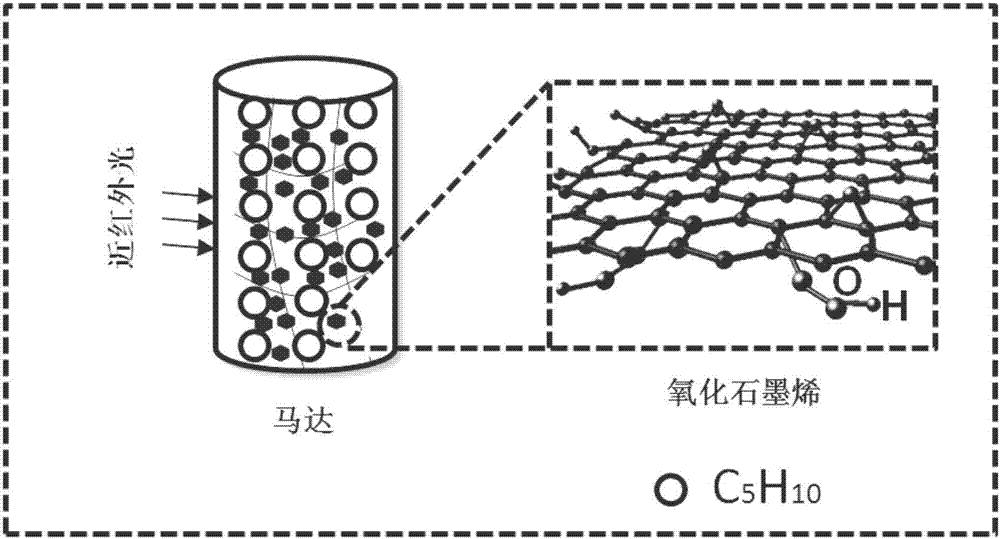

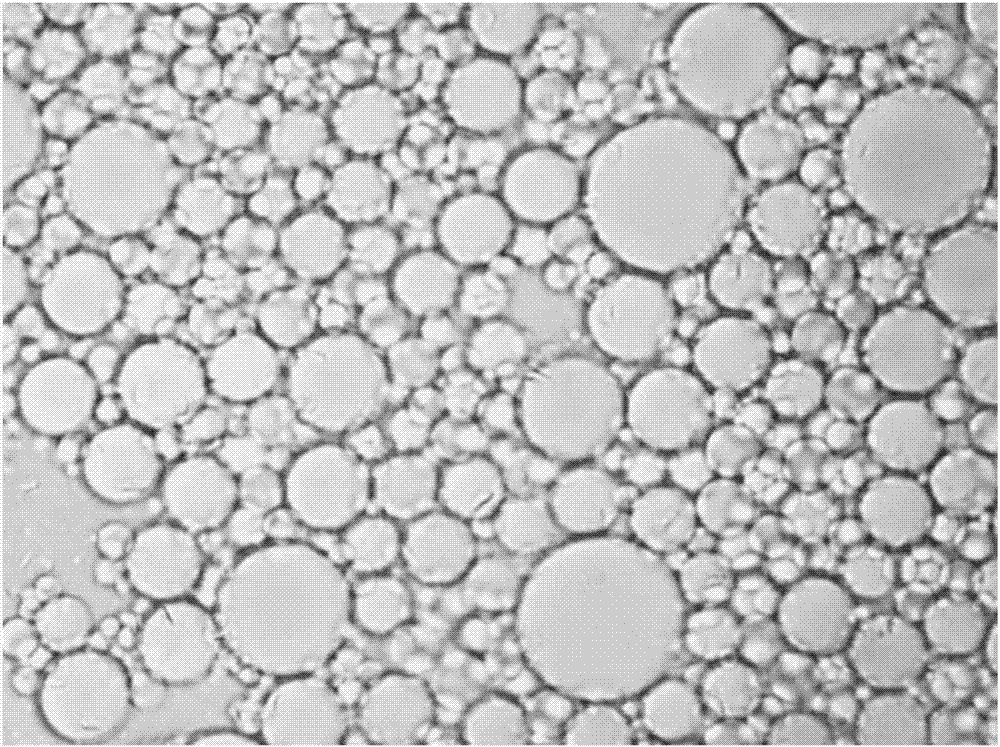

[0036] A method for preparing an infrared laser-driven hydrogel motor, comprising the following steps:

[0037] (1) Graphene oxide (GO) was prepared by using natural graphite powder through the improved Hummers method; graphene oxide nanosheets were added to deionized water, and ultrasonically treated for 2 hours under ice-water bath conditions to obtain a uniform GO dispersion, Take 6mL of 4mg / mL GO dispersion;

[0038] (2) Take 40 μL of Tween 80 emulsifier, dissolve it in 6 mL of GO dispersion, and process it ultrasonically for 10 minutes to obtain a uniform emulsifier dispersion;

[0039] (3) Add 1.2g of acrylamide monomer, 0.6mg of N,N-methylenebisacrylamide and 0.06g of potassium persulfate initiator to the dispersion obtained in step (2), and oscillate for 1min with ultrasonic waves Afterwards, logical nitrogen deoxygenation is obtained as the water phase of oil-in-water emulsion;

[0040] (4) Add 12 mL of cyclopentane as the oil phase to the water phase obtained in st...

Embodiment 2

[0045] A method for preparing an infrared laser-driven hydrogel motor, comprising the following steps:

[0046] (1) Graphene oxide (GO) was prepared by using natural graphite powder through the Brodie method; graphene oxide nanosheets were added to deionized water, and ultrasonically treated for 4 hours under ice-water bath conditions to obtain a uniform GO dispersion. Take 6mL 12mg / mL GO dispersion;

[0047] (2) Take 30 μL of Tween 80 emulsifier, dissolve it in 6 mL of GO dispersion, and process it ultrasonically for 10 minutes to obtain a uniform emulsifier dispersion;

[0048] (3) Add 1.2g of acrylamide monomer, 0.6mg of N,N-methylenebisacrylamide and 0.06g of potassium persulfate initiator to the dispersion obtained in step (2), and oscillate for 2 minutes with ultrasonic waves Afterwards, logical nitrogen deoxygenation is obtained as the water phase of oil-in-water emulsion;

[0049] (4) Add 6 mL of cyclohexane as the oil phase to the water phase obtained in step (3), a...

Embodiment 3

[0054] A method for preparing an infrared laser-driven hydrogel motor, comprising the following steps:

[0055] (1) Graphene oxide (GO) was prepared by using natural graphite powder by the Staudenmaier method; graphene oxide nanosheets were added to deionized water, and ultrasonically treated for 2 hours under ice-water bath conditions to obtain a uniform GO dispersion. Take 6mL 2mg / mL GO dispersion;

[0056] (2) Take 40 μL of Tween 60 emulsifier, dissolve it in 6 mL of GO dispersion, and process it ultrasonically for 10 minutes to obtain a uniform emulsifier dispersion;

[0057] (3) Take 0.6g of acrylamide monomer, 0.6g of isopropylacrylamide, 1.2mg of N,N-methylene bisacrylamide and 0.12g of potassium persulfate initiator to add the obtained in step (2) In the dispersion liquid, after oscillating with ultrasonic wave for 1 min, deoxygenate with nitrogen gas to obtain the water phase as an oil-in-water emulsion;

[0058] (4) The n-hexane of 12mL is used as the oil phase, jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com