Short polyamide 5X fiber and preparation method and application

A polyamide and staple fiber technology, applied in the direction of single-component polyamide rayon, single-component copolyamide rayon, melt spinning, etc., can solve the difficulties of subsequent spinning, low elongation, and inability to Meet other issues, to achieve the effect of reducing greenhouse effect, reducing emissions, improving durability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102]

[0103] A preparation method of polyamide 5X short fiber, it may further comprise the steps:

[0104] (1) Polymerizing 1,5-pentamethylenediamine and dicarboxylic acid to form a polyamide 5X melt; or, heating polyamide 5X (polyamide 5X resin) to a molten state to form a polyamide 5X melt;

[0105] (2), the polyamide 5X melt is spun to form spun silk;

[0106] (3) Polyamide 5X staple fibers are obtained after the as-spun silk is processed.

[0107] Wherein, in the step (1), the polyamide 5X is a polyamide 5X resin chip.

[0108] The relative viscosity of polyamide 5X resin chip can be 2.65-3.00.

[0109] Because polyamide 5X resin has stronger water absorption, therefore, can carry out drying before it is heated and melted, and drying temperature is 100-150 ℃, and drying time is 10-30 hours, and the polyamide 5X resin after drying The moisture content is 50-1500ppm, preferably 200-800ppm, more preferably 300-700ppm, further preferably 400-600ppm.

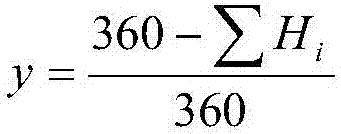

[0110] The spinn...

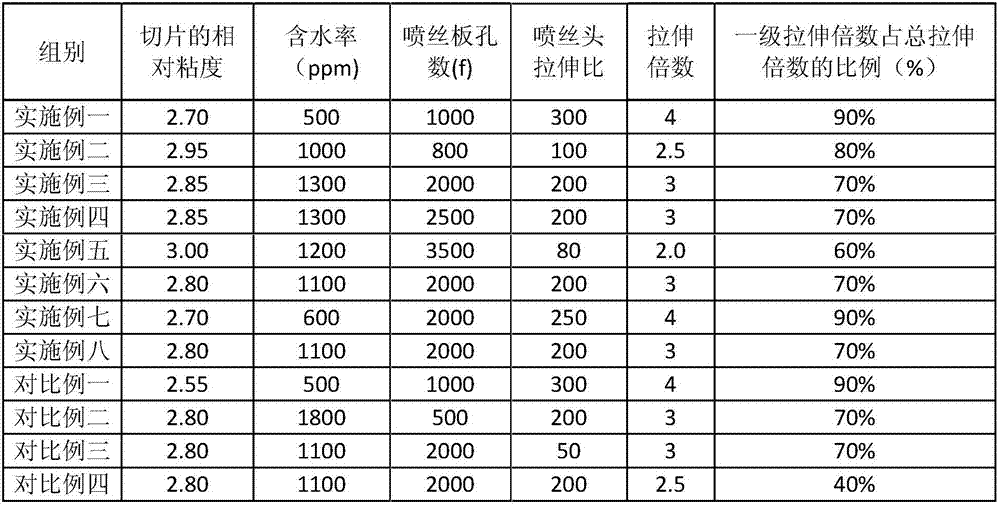

Embodiment 1

[0145] The present embodiment provides a kind of preparation method of polyamide 56 short fiber, it comprises the steps:

[0146] (1), select polyamide 56 slices with a relative viscosity of 2.70, dry under nitrogen protection, the drying temperature is 135°C, and the drying time is 16h. The moisture content of the dried polyamide 56 resin slices is 500ppm, and the dried polyamide The 56 slices enter the single-screw machine through the sealed nitrogen protection silo for heating and melting to obtain the polyamide 56 melt;

[0147] (2), polyamide 56 melt is sprayed out by the spinneret that number of holes is 1000f, and spinneret drawing ratio is 300, and after polyamide 56 melt sprays out spinneret hole, cools by ring blowing, and wind temperature is 25°C, with a wind speed of 0.8m / s, to obtain as-spun silk;

[0148] (3), as-spun silk is fed into the silk barrel by feeding rollers to obtain raw silk, and the raw silk is stretched in three stages by cluster frame, and the to...

Embodiment 2

[0151] The present embodiment provides a kind of preparation method of polyamide 56 short fiber, it comprises the steps:

[0152] (1), select polyamide 56 slices with a relative viscosity of 2.95, dry under nitrogen protection, the drying temperature is 135°C, and the drying time is 10h. The moisture content of the dried polyamide 56 resin slices is 1000ppm, and the dried polyamide The 56 slices enter the single-screw machine through the sealed nitrogen protection silo for heating and melting to obtain the polyamide 56 melt;

[0153] (2), polyamide 56 melt is sprayed out by the spinneret plate that number of holes is 800f, and spinneret drawing ratio is 100, and after polyamide 56 melt is sprayed out spinneret hole, cools by ring blowing, and wind temperature is 25°C, with a wind speed of 0.5m / s, to obtain as-spun silk;

[0154] (3), as-spun silk is fed into the silk barrel by feeding rollers to obtain raw silk, and the raw silk is stretched in three stages by cluster frame, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com