Microencapsulated peony seed oil, compound composition and preparation method of microencapsulated peony seed oil

A technology of compound composition and peony seed oil, which is applied in food science, edible oil/fat, and the function of food ingredients, etc., can solve the problem of not considering other components of peony seed oil, wall material without antioxidant activity, capsule particles Inhomogeneity and other problems, to achieve high microencapsulation yield, strong antioxidant activity, and reduce high blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

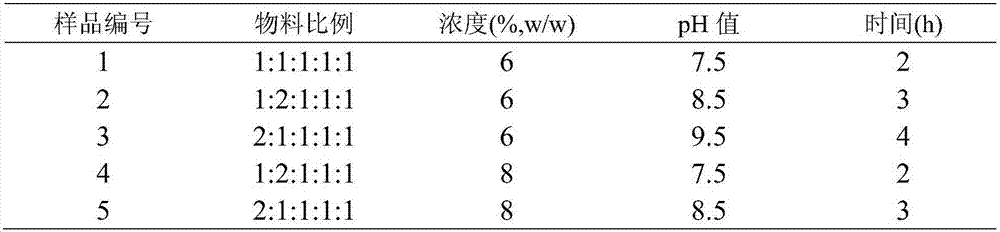

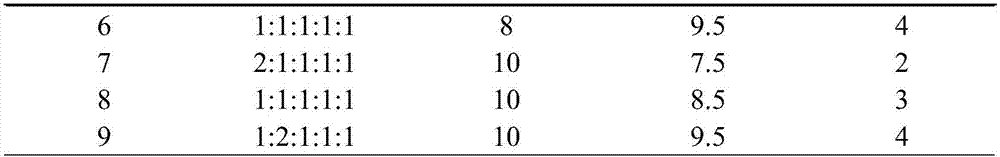

[0033] Example 1 Preparation of Microencapsulated Peony Seed Oil

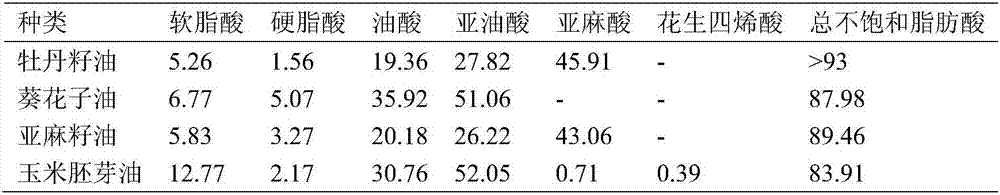

[0034] (1) Preparation of peony seed oil

[0035] Take an appropriate amount of peony seeds produced in Heze, dry them at 40°C, ultrafinely pulverize them through an 80-mesh sieve, accurately weigh an appropriate amount of peony seed powder, seal the filling, and use supercritical CO 2 Extraction technology, the extraction pressure is 35MPa, the extraction temperature is 45°C, CO 2 Flow 30L·h -1 Under the condition of extraction for 2.5h, the primary extract of peony seed oil was obtained by separation under reduced pressure. Adopt hydration method degumming subsequently (under the condition of 50 ℃, add water temperature and oil temperature are basically the same, add water is 4%), molecular distillation method deacidification, activated clay secondary adsorption decolorization (add soil amount is 6%, decolorization temperature is 40°C, the decolorization time is 10min), and the refined peony seed oil is ob...

Embodiment 2

[0042] Example 2 Preparation of Microencapsulated Peony Seed Oil Compound Solid Granules

[0043] (1) Raw material sieving: pass the microencapsulated peony seed oil, folic acid and xylo-oligosaccharide raw materials through an 80-mesh sieve, so that the particle size of each raw material is similar;

[0044] (2) Mixing: All the sieved raw materials are fully mixed according to the weight ratio of 850 parts of microencapsulated peony seed oil, 0.02 parts of folic acid, and 150 parts of xylooligosaccharides to obtain the mixed material;

[0045] (3) Packaging: every 10 g of the mixed raw materials is a packaging unit, and the microencapsulated peony seed oil complex solid granule is obtained.

[0046] The folic acid is purchased from Shaanxi Kangyue Biotechnology Co., Ltd., with a purity of 99%, which meets the requirements of health food raw materials.

[0047] The xylo-oligosaccharide is purchased from Shandong Longli Biotechnology Co., Ltd., with a purity of 99%, which meet...

Embodiment 3

[0048] Example 3 Preparation of Microencapsulated Peony Seed Oil Compound Granules

[0049] (1) Raw material sieving: pass the microencapsulated peony seed oil, folic acid and xylo-oligosaccharide raw materials through an 80-mesh sieve, so that the particle size of each raw material is similar;

[0050] (2) Mixing: All the sieved raw materials are fully mixed according to the weight ratio of 800 parts of microencapsulated peony seed oil, 0.01 part of folic acid, and 200 parts of xylooligosaccharides to obtain the mixed material;

[0051] (3) Granulation: Add the mixed material into the granulator and heat it to granulate. Mix for 10 minutes first. When the air outlet temperature reaches 40°C, spray 95wt% ethanol solution and dry at 50°C to control the water content of the material at 3.0 wt% or less, then pass through a 14-mesh nylon sieve for sizing;

[0052] (4) Packaging: every 10 g is a packaging unit, and the microencapsulated peony seed oil compound granules are obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com