Low-GI high-fiber noodle and preparation method thereof

A noodle and high-fiber technology, which is applied in the direction of food ingredients as taste improvers, functions of food ingredients, food science, etc., can solve the problems of inability to scientifically regulate the ratio of soluble and insoluble dietary fiber, thermodynamic incompatibility of main ingredients of noodles, and influence Taste and cooking properties, etc., to reduce thermodynamic incompatibility, improve taste and cooking properties, reduce taste and cooking loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

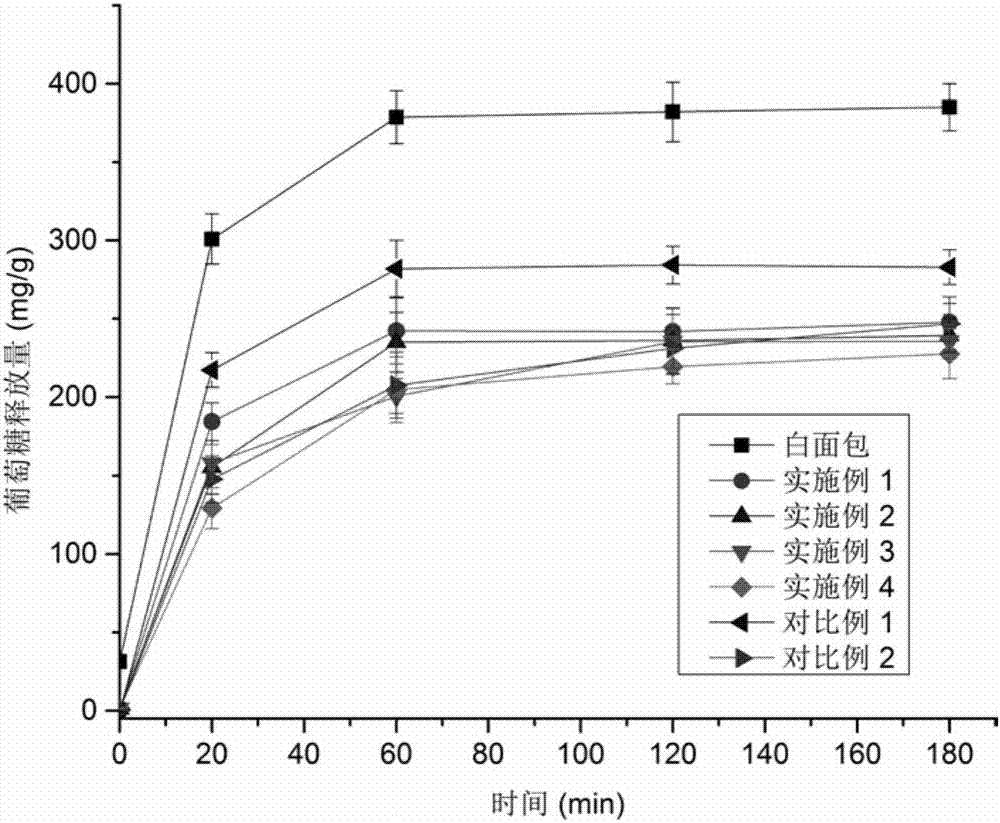

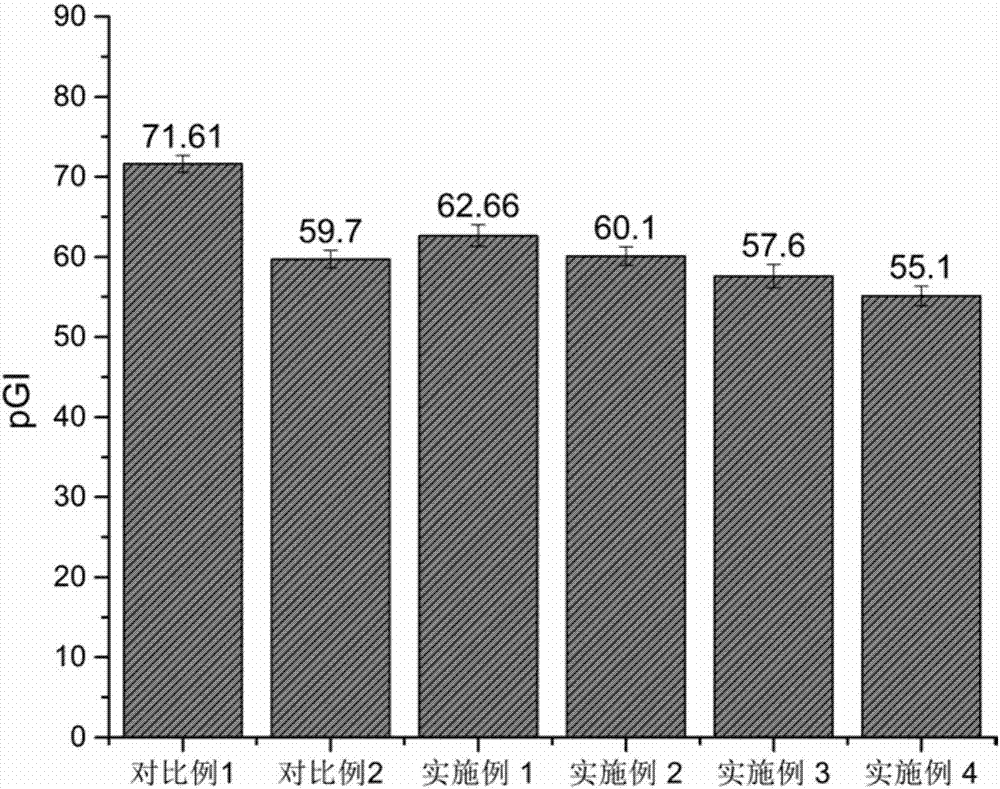

Examples

Embodiment 1

[0033] 1. Raw materials:

[0034] Powder 100kg: high-gluten wheat flour 88.5%; oat bran dietary fiber 5%; konjac glucomannan 2.5%; gluten powder 3%; edible salt 1%;

[0035] 39kg of water.

[0036] 2. Preparation method

[0037] (1) edible salt is dissolved in water to make brine;

[0038] (2) Mix high-gluten wheat flour, oat bran dietary fiber, konjac glucomannan and gluten powder, add salt water, knead the dough for 15 minutes, and mature at 25°C for 20 minutes;

[0039] (3) The cooked dough is made into noodles through composite calendering, and dried for 30 hours at 25° C. and with a humidity of 65-75% to obtain dry noodles. The noodles prepared in this experiment are uniform in color, slightly brown, with a slight oatmeal flavor, without sour, musty and other peculiar smells. The taste is smooth, not sticky to the teeth, and chewy.

Embodiment 2

[0041] 1. Raw materials:

[0042]Powder 100kg: high-gluten wheat flour 83.5%; oat bran dietary fiber 10%; konjac glucomannan 2.5%; gluten 3%; edible salt 1%;

[0043] 40kg of water.

[0044] 2. Preparation method

[0045] (1) edible salt is dissolved in water to make brine;

[0046] (2) Mix high-gluten wheat flour, oat bran dietary fiber, konjac glucomannan and gluten powder, add salt water, knead the dough for 20 minutes, and mature at 20°C for 30 minutes;

[0047] (3) Stretching the matured dough to make noodles, drying at 30°C and 65-75% humidity for 24 hours to make dry noodles. The noodles prepared in this example are uniform in color, yellowish brown, slightly oat-like, and free from sour, musty and other peculiar smells. The taste is smooth, not sticky to the teeth, and has good palatability.

Embodiment 3

[0049] 1. Raw materials:

[0050] Powder 100kg: high-gluten wheat flour 78.5%; oat bran dietary fiber 15%; konjac glucomannan 2.5%; gluten powder 3%; edible salt 1%;

[0051] 42kg of water.

[0052] 2. Preparation method

[0053] (1) edible salt is dissolved in water to make brine;

[0054] (2) Mix high-gluten wheat flour, oat bran dietary fiber, konjac glucomannan and gluten powder, add salt water, knead the dough for 18 minutes, and mature at 22°C for 25 minutes;

[0055] (3) Stretching the matured dough to make noodles, drying at 28°C and 65-75% humidity for 27 hours to make dry noodles. The noodles prepared in this example are uniform in color, yellowish brown, slightly oat-like, and free from sour, musty and other peculiar smells. The taste is smooth, non-sticky, and resistant to cooking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com