High-temperature-resistant paper pouring pipe for producing metal casting and preparing method of high-temperature-resistant paper pouring pipe

A technology of metal casting and high temperature resistance, which is applied in the production of high temperature resistant paper pouring pipes for metal casting and its preparation, which can solve the problems of high processing costs of non-renewable resources, and achieve the effects of light weight, improved quality, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

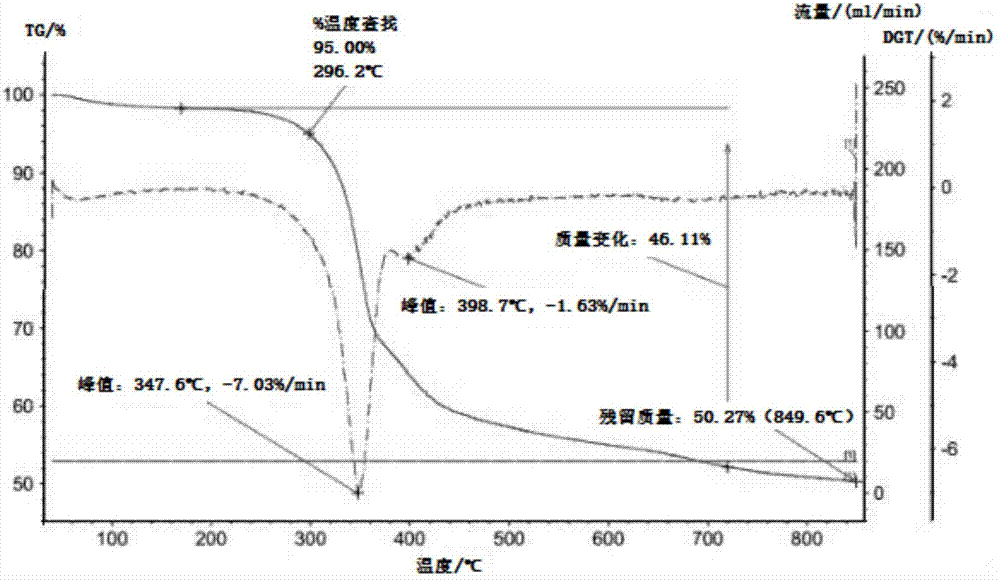

Image

Examples

Embodiment 1

[0049] Embodiment 1, a kind of preparation method that is used for producing high temperature resistant paper pouring pipe for metal casting, carries out following steps successively:

[0050] a. Preparation of waste paper pulp:

[0051] Add the collected waste printed matter or / and waste cardboard and other waste paper materials into the pulper at room temperature and water at a weight ratio of 1:15 to prepare pulp, and then directly put the pulp into the dehydration container or dehydration equipment Dehydrated to make the water content ≤ 55%, for later use;

[0052] b. Preparation of filling materials and paper fiber modified materials:

[0053] Filling materials are: 200 mesh corundum fine powder, 200 mesh mullite fine powder, 200 mesh montmorillonite fine powder, 200 mesh andalusite fine powder;

[0054] The paper fiber modified material is obtained by mixing boron modified phenolic resin (FB resin): epoxy resin (E-44) = 1:1 mass ratio.

[0055] c. Weigh the above prep...

Embodiment 2

[0066] Embodiment 2, a kind of preparation method that is used for producing high temperature resistant paper pouring tube for metal casting,

[0067] Its formulation is composed of the following components by weight, calculated on dry matter:

[0068]

[0069] Paper fiber modified material (boron modified phenolic resin (FB resin): epoxy resin (E-44) = 1:1) 1.5%;

[0070] Step f) is a modification reaction at 140°C for 3 hours;

[0071] The rest are equal to Example 1.

Embodiment 3

[0072] Embodiment 3, a kind of preparation method that is used for producing high temperature resistant paper pouring tube for metal casting,

[0073] In step a), the weight ratio of waste paper material to water is 1:10;

[0074] Its formulation is composed of the following components by weight, calculated on dry matter:

[0075]

[0076] Paper fiber modified material (boron modified phenolic resin (FB resin): epoxy resin (E-44) = 1:1) 2%;

[0077] Step f) is a modification reaction at 130°C for 4 hours;

[0078] The rest are equal to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com