Water treatment biological membrane reactor

A technology of biofilm reactor and water treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem that aerobic and anaerobic bacteria cannot coexist and need to be separated Treatment, high energy consumption, easy blockage of water treatment structures and other problems, to achieve good environmental protection value, low energy consumption, and good industrialization promotion advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

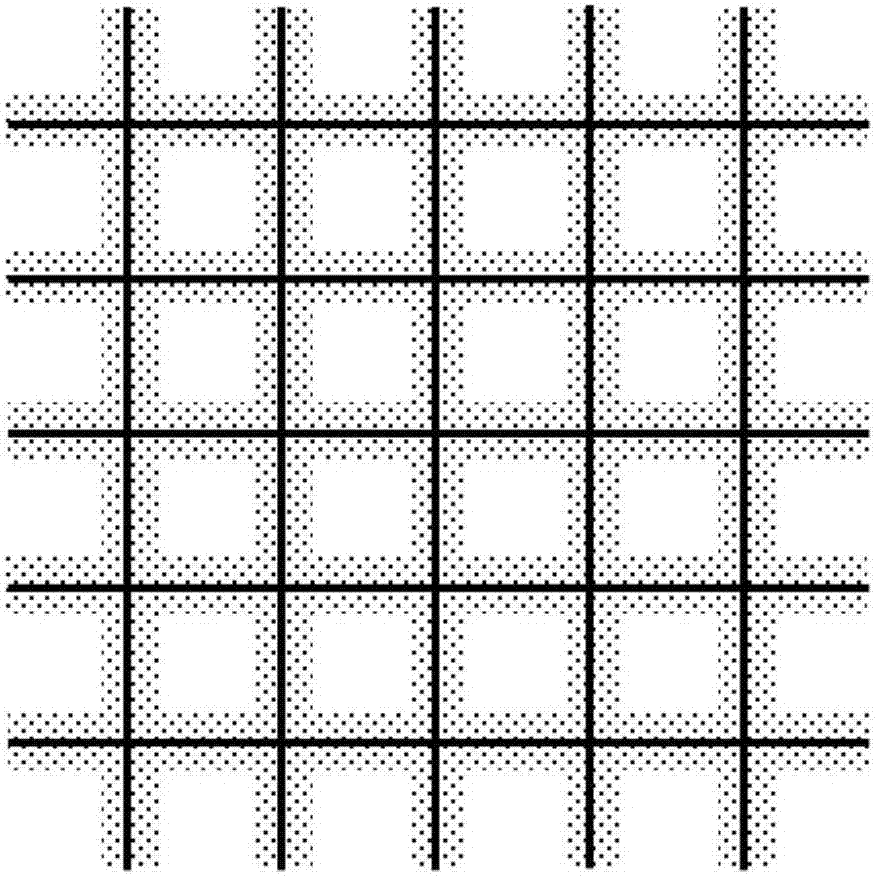

[0034] A water treatment biofilm reactor, such as figure 1 As shown, it is mainly composed of a substrate and an attachment directly attached to the surface of the substrate. The substrate is a flat mesh structure, the material of the substrate is PET, the thickness of the substrate is 0.1mm, the aperture of the substrate mesh is 10 mesh, and the unit of the substrate The weight is 10g / m 2 , The tear strength of the matrix in any direction is 20N, and the matrix has excellent hydrolysis resistance. Under the natural conditions of contact with water, the tear strength in any direction has a one-year retention rate of 60% and a two-year retention rate The attachment is sodium polyacrylate with a volume expansion rate of 8000% after water absorption. The molecular weight of sodium polyacrylate is 100,000. The attachments are evenly distributed on the surface of the substrate. The content of attachments per unit surface of the substrate is 0.15g / m 2 .

Embodiment 2

[0036] A water treatment biofilm reactor, such as figure 1 As shown, it is mainly composed of a substrate and an attachment adhered to the surface of the substrate through an adhesive. The substrate is a flat mesh structure. The material of the substrate is a PET / PP composite (mass ratio 1:1), and the thickness of the substrate is 5mm. The aperture of the matrix mesh is 1000 meshes, and the unit weight of the matrix is 1000g / m 2 , The tear strength of the matrix in any direction is 80N, and the matrix has excellent hydrolysis resistance. Under the natural conditions of contact with water, the tear strength in any direction has a one-year retention rate of 85% and a two-year retention rate 60%, the attachment is a polymer substance containing porous powder, the content of the porous powder is 10% of the weight of the attachment, the polymer substance is polyacrylamide with a volume expansion rate of 7000% after saturated water absorption, The molecular weight is 1 million, the...

Embodiment 3

[0038] A water treatment biofilm reactor, such as figure 1 As shown, it is mainly composed of a substrate and an attachment directly attached to the surface of the substrate. The substrate is a flat mesh structure. The material of the substrate is glass fiber. The thickness of the substrate is 0.5mm. The pore size of the substrate is 50 mesh. Unit weight is 50g / m 2 , The tear strength of the matrix in any direction is 50N, and the matrix has excellent hydrolysis resistance. Under the natural conditions of contact with water, the tear strength in any direction has a one-year retention rate of 75% and a two-year retention rate 36%, the attachment is a polymer substance containing porous powder, the content of the porous powder is 5% of the weight of the attachment, the polymer substance is agar with a volume expansion rate of 1100% after saturated water absorption, and the molecular weight of the agar is 10,000 The porous powder is diatomaceous earth with a particle size of 10μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com