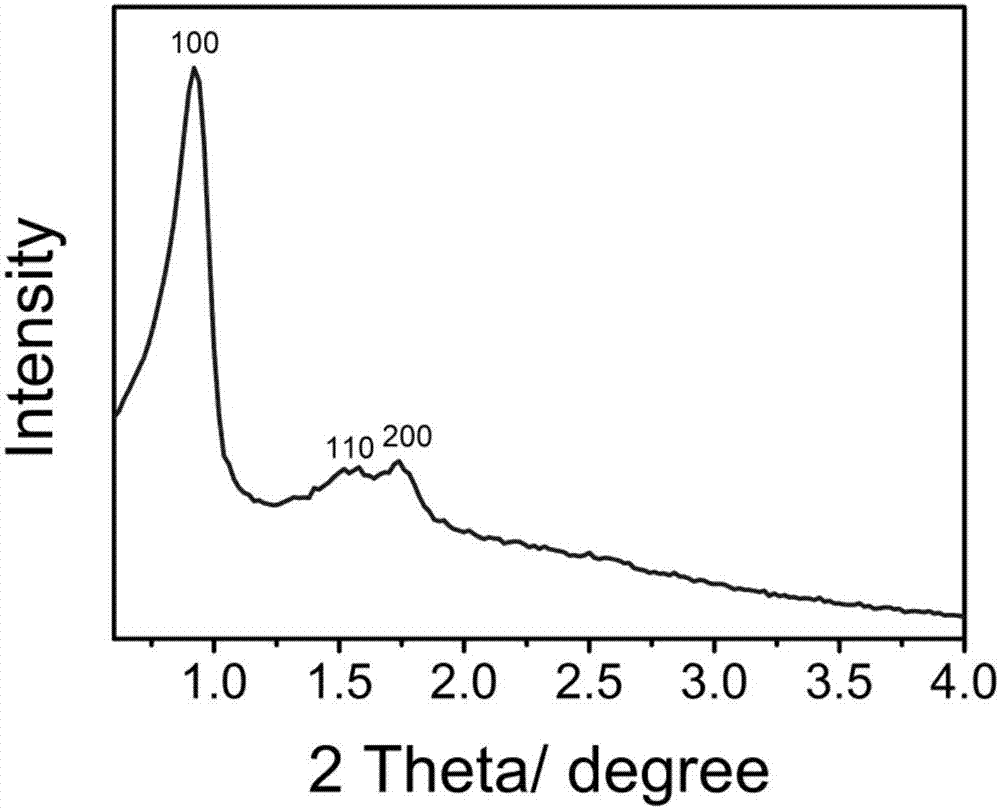

Method used for preparing iron-doped SBA-15 mesoporous molecular sieve under neutral conditions via one-step method

A technology of mesoporous molecular sieves and neutral conditions, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

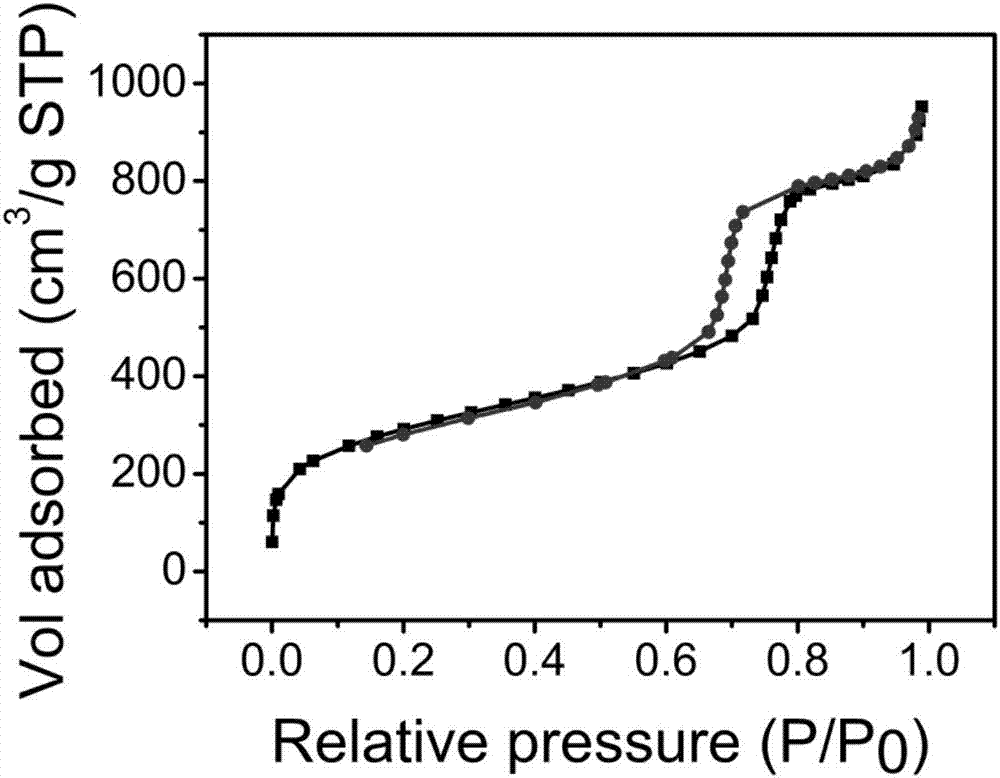

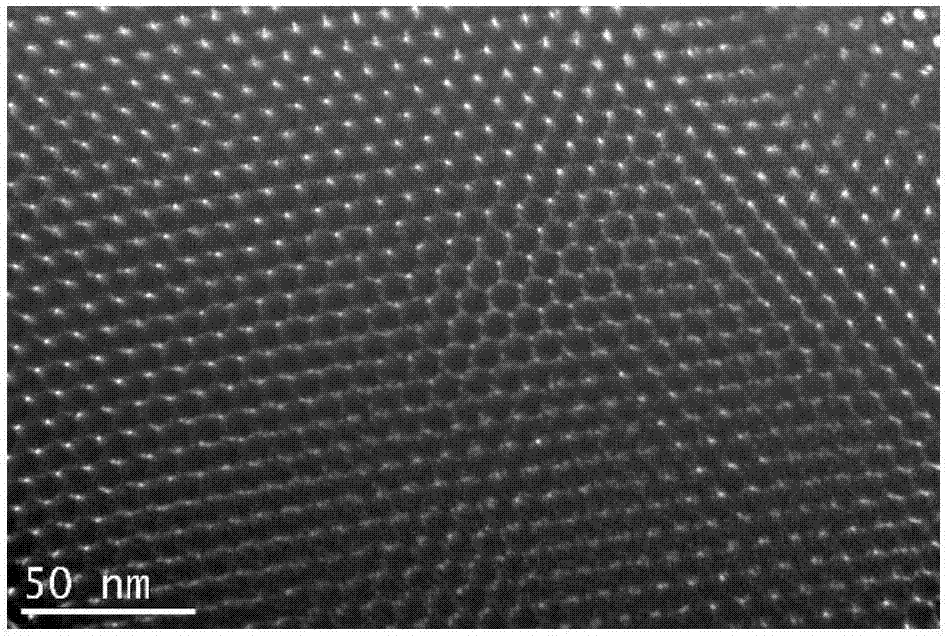

[0023] This embodiment provides the preparation method of introducing Fenton's reagent to synthesize Fe-SBA-15 mesoporous molecular sieve in one step:

[0024] Get 4g tetraethyl orthosilicate and 15g deionized water and mix together and add in the quartz vessel, stir with a stirrer at 300 rpm, add Fenton's reagent (300uL of 1M FeSO 4 ·7H 2 O aqueous solution and 600 uL mass fraction of 35% H 2 o 2 Mixing of aqueous solutions, FeSO 4 ·7H 2 O and H 2 o 2 The quality of each is 0.08g and 0.02g), stirring continuously for 1 hour, it becomes orange-yellow homogeneous solution A, 2g P 123 Mix it with 85g deionized water and add it to the beaker, stir it with a stirrer at 300 rpm for 6 hours to make it a clear solution B, add solution B dropwise to solution A at 20mL / min to obtain Fe-SBA-15 mediated Porous molecular sieve initial sol, and then continue stirring at 40°C and 300 rpm for 24 hours, then transfer it to the reactor. The total mass ratio of each reactant in the react...

Embodiment 2

[0032] This embodiment provides the preparation method of introducing Fenton's reagent (reducing Fe content) one-step synthetic Fe-SBA-15 mesoporous molecular sieve:

[0033] Take 4g of tetraethyl orthosilicate and 15g of deionized water and mix them into a quartz vessel, stir with a mixer at 300 rpm, and add Fenton's reagent (200uL, 1M FeSO 4 ·7H 2 O and 600uL, mass fraction 35%H 2 o 2 Mixing of aqueous solutions, FeSO 4 ·7H 2 O and H 2 o 2 The quality of each is 0.06g and 0.02g), stirring continuously for 1 hour, it becomes orange-yellow homogeneous solution A, 2g P 123 Mix it with 45g deionized water and add it to the beaker, stir it with a stirrer at 300 rpm for 6 hours to make it a clear solution B, add solution B dropwise to solution A at 20mL / min to obtain Fe-SBA-15 medium Porous molecular sieve initial sol, then continue to stir at 40°C and 300 rpm for 24 hours, transfer it to the reactor, so that the total mass ratio of the reactants in the reactor is TEOS:P 1...

Embodiment 3

[0036] This embodiment introduces the preparation method of Fenton's reagent (increase Fe content) one-step synthesis Fe-SBA-15 mesoporous molecular sieve:

[0037] Take 4g of tetraethyl orthosilicate and 15g of deionized water and mix them into a quartz vessel, stir with a mixer at 300 rpm, and add Fenton's reagent (500uL, 1M FeSO 4 ·7H 2 O and 1800uL, mass fraction 35%H 2 o 2 Mixing of aqueous solutions, FeSO 4 ·7H 2 O and H 2 o 2 The quality of each is 0.14g and 0.06g), stirring continuously for 1 hour, it becomes orange-yellow homogeneous solution A, 2g P 123 Mix it with 85g deionized water and add it to the beaker, stir it with a stirrer at 300 rpm for 6 hours to make it a clear solution B, add solution B dropwise to solution A at 20mL / min to obtain Fe-SBA-15 medium Porous molecular sieve initial sol, then continue to stir at 40°C and 300 rpm for 24 hours, transfer it to the reactor, so that the total mass ratio of the reactants in the reactor is TEOS:P 123 : FeSO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com