Dressing-metallurgy combination recycling method for solid inclusion copper oxide ore

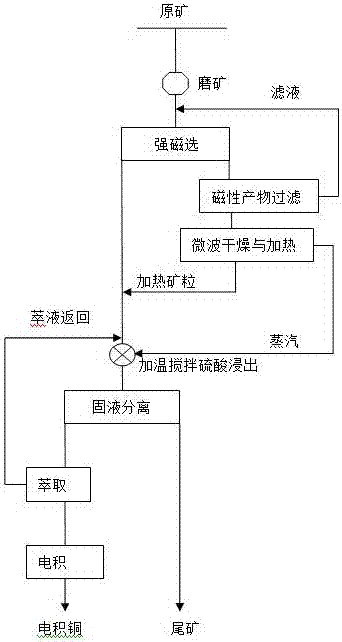

A combined technology of copper oxide ore and beneficiation and metallurgy, applied in the field of beneficiation and metallurgy, can solve the problems of unsatisfactory effect, single dispersion and inhibition of ore slime, single heating, etc., and achieves obvious leaching effect, reduction of ore amount, and temperature rise. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw materials: copper grade 1.5%, oxidation rate greater than 95%, copper distribution rate in free copper oxide ore is less than 40%, copper distribution rate of limonite, hematite, biotite wrapped 60% solid inclusion oxidation copper ore.

[0026] (1) Ore crushing and grinding, the grinding fineness is -0.074mm, the mass percentage accounts for 70%, the mass percentage concentration of the pulp after grinding is 35%, and the strong magnetic field magnetic separation with a magnetic induction intensity of 1.6T is adopted The iron and biotite minerals wrapped in copper are recovered by mechanical magnetic separation to obtain magnetic separation concentrate, and the magnetic separation concentrate is filtered, and the filtrate is returned to the magnetic separation operation, and the magnetic separation tailings containing free copper oxide are obtained at the same time;

[0027] (2) The magnetic separation concentrate is dried and heated by a continuous chemical indust...

Embodiment 2

[0032] Raw materials: copper grade 1.0%, oxidation rate greater than 95%, copper distribution rate in free copper oxide ore is less than 40%, copper distribution rate of limonite, hematite, biotite wrapped 53% solid inclusion oxidation copper ore.

[0033] (1) First crush and grind the ore, the grinding fineness is -0.074mm, the mass percentage accounts for 75%, the mass percentage concentration of the pulp after grinding is 40%, and the strong magnetic field magnetic separation with a magnetic induction intensity of 1.3T is adopted The iron and biotite minerals wrapped in copper are recovered by mechanical magnetic separation to obtain magnetic separation concentrate, and the magnetic separation concentrate is filtered, and the filtrate is returned to the magnetic separation operation, and the magnetic separation tailings containing free copper oxide are obtained at the same time;

[0034] (2) The magnetic separation concentrate is dried and heated by a continuous chemical in...

Embodiment 3

[0039] Raw materials: copper grade 0.8%, oxidation rate greater than 95%, copper distribution rate in free copper oxide ore is less than 40%, copper distribution rate of limonite, hematite, biotite wrapped 50% solid inclusion oxidation copper ore.

[0040] (1) Ore crushing and grinding, the grinding fineness is -0.074mm, the mass percentage accounts for 80%, the mass percentage concentration of the pulp after grinding is 38%, and the magnetic field magnetic separator with a magnetic induction intensity of 1.0T is used. Collect iron and biotite minerals wrapped in copper to obtain magnetic separation concentrate, and filter the magnetic separation concentrate, the filtrate is returned to the magnetic separation operation, and at the same time obtain the magnetic separation tailings containing free copper oxide, which is produced by drying the magnetic separation concentrate The steam is used to supplement the heating magnetic separation tailings slurry;

[0041] (2) The magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com