A low-cost method for preparing mo2feb2-based cermets

A cermet, mo2feb2 technology, applied in the field of preparation of low-cost Mo2FeB2-based cermets, to achieve the effect of improving mechanical properties, reducing preparation costs, and increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

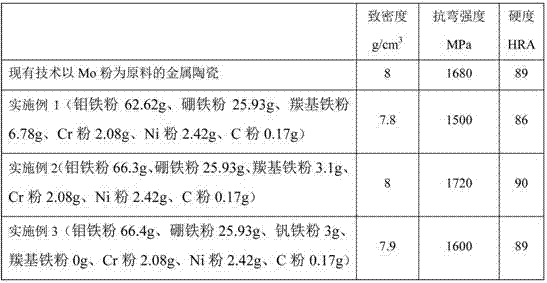

Embodiment 1

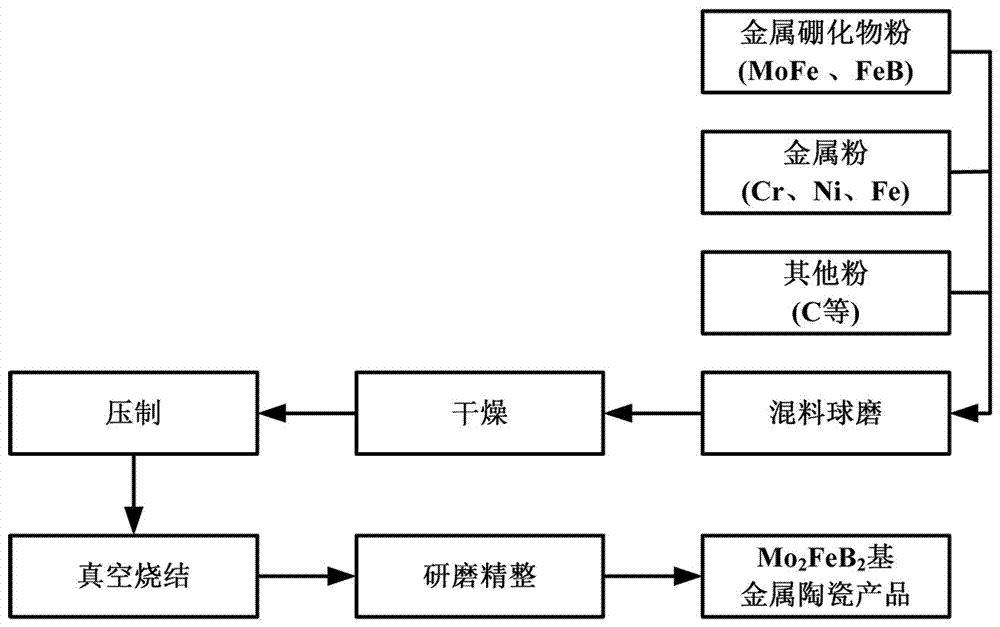

[0031] like figure 1 As shown, a low-cost Mo 2 FeB 2 The preparation method of base cermet, it comprises the steps:

[0032] (1) Ingredients: Weigh 62.62g of ferromolybdenum powder, 25.93g of ferroboron powder, 6.78g of carbonyl iron powder, 2.08g of Cr powder, 2.42g of Ni powder, and 0.17g of C powder as reaction raw materials, totaling 100g.

[0033] (2) Mixed ball mill: Put the prepared powder and cemented carbide balls into the ball mill and wet them for 48 hours. The ratio of balls to materials is 5:1. The ball milling medium is absolute ethanol. 1:1, ball mill speed is 250rad / min;

[0034] (3) Drying: put the ball-milled mixture into a drying oven to dry, and keep it warm at 80°C for 2 hours;

[0035] (4) Compression: The dried powder is molded at room temperature to obtain a rectangular compact of 7mm×7mm×30mm, with a pressure of 350MPa;

[0036] (5) Vacuum sintering: The cermet is prepared by vacuum sintering, the sintering temperature is 1200°C, and the holding t...

Embodiment 2

[0040] like figure 1 As shown, a low-cost Mo 2 FeB 2 The preparation method of base cermet, it comprises the steps:

[0041] (1) Ingredients: Weigh 66.3g of ferromolybdenum powder, 25.93g of ferroboron powder, 3.1g of carbonyl iron powder, 2.08g of Cr powder, 2.42g of Ni powder, and 0.17g of C powder as reaction raw materials, totaling 100g.

[0042] (2) Mixed ball mill: Put the prepared powder and cemented carbide balls into the ball mill and wet them for 48 hours. The ratio of balls to materials is 5:1. The ball milling medium is absolute ethanol. 1:1, ball mill speed is 250rad / min;

[0043] (3) Drying: put the ball-milled mixture into a drying oven to dry, and keep it warm at 80°C for 2 hours;

[0044] (4) Compression: The dried powder is molded at room temperature to obtain a rectangular compact of 7mm×7mm×30mm, with a pressure of 350MPa;

[0045] (5) Vacuum sintering: The cermet is prepared by vacuum sintering, the sintering temperature is 1200°C, and the holding tim...

Embodiment 3

[0049] like figure 1 As shown, a low-cost Mo 2 FeB 2 The preparation method of base cermet, it comprises the steps:

[0050] (1) Ingredients: Weigh 66.4g of ferromolybdenum powder, 25.93g of ferroboron powder, 3g of ferrovanadium powder, 0g of carbonyl iron powder, 2.08g of Cr powder, 2.42g of Ni powder, and 0.17g of C powder as reaction raw materials, totaling 100g.

[0051] (2) Mixed ball mill: Put the prepared powder and cemented carbide balls into the ball mill and wet them for 48 hours. The ratio of balls to materials is 5:1. The ball milling medium is absolute ethanol. 1:1, ball mill speed is 250rad / min;

[0052] (3) Drying: put the ball-milled mixture into a drying oven to dry, and keep it warm at 80°C for 2 hours;

[0053] (4) Compression: The dried powder is molded at room temperature to obtain a rectangular compact of 7mm×7mm×30mm, with a pressure of 350MPa;

[0054] (5) Vacuum sintering: The cermet is prepared by vacuum sintering, the sintering temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com