Tarpaulin taking filament spunbond nonwoven fabric as base cloth and production method thereof

A production method and technology for non-woven fabrics, applied in textiles and papermaking, heating/cooling fabrics, building elements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

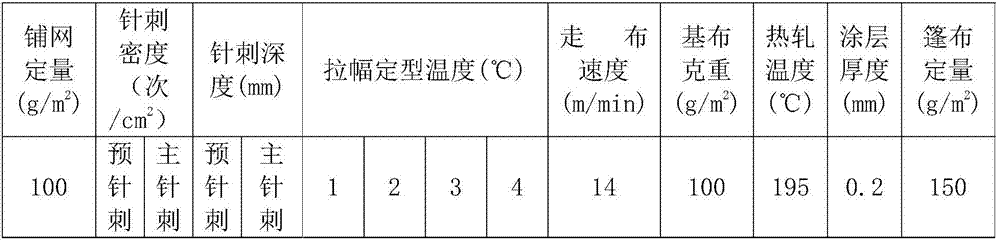

[0057] In this embodiment, the selected viscosity is 0.700 fiber-grade PET slices to produce the base fabric, the spinning metering pump is 15 turns, the production line production speed is 14m / min, and the net laying weight is 100g / m 2 .

[0058] The specific production method is as follows:

[0059] Base fabric processing, PET slices are made into base fabric through the processes of crystallization drying, melt extrusion, spinning cooling, filament laying, acupuncture reinforcement and tentering;

[0060] Functional coating treatment, the base fabric is made into the tarpaulin through the processes of hot rolling and shaping, functional finishing, knife coating and calender cooling;

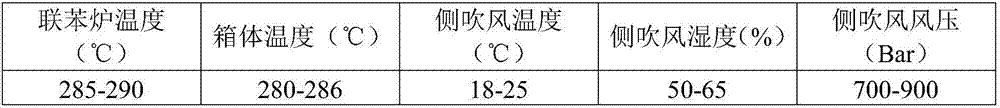

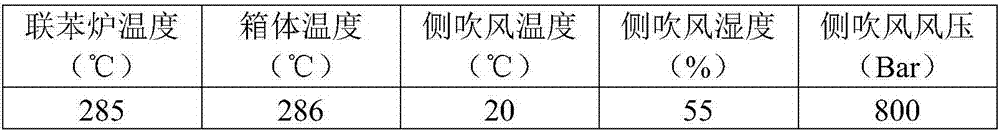

[0061] Among them, the crystallization temperature of crystallization drying is 162°C, the crystallization time is 30min, the drying temperature is 172°C, and the drying time is 8h; the process temperature of each zone of the extruder for melt extrusion is shown in Table 3; the spinning proce...

Embodiment 2

[0072] In this embodiment, the fiber-grade PET slices with a selected viscosity of 0.700 are used to produce the base fabric, the spinning metering pump is 18 turns, the production line production speed is 12m / min, and the net laying weight is 150g / m 2 .

[0073] The specific production method is as follows:

[0074] Base fabric processing, PET slices are made into base fabric through the processes of crystallization drying, melt extrusion, spinning cooling, filament laying, acupuncture reinforcement and tentering;

[0075] Functional coating treatment, the base fabric is made into the tarpaulin through the processes of hot rolling and shaping, functional finishing, knife coating and calender cooling;

[0076] Among them, the crystallization temperature of crystallization drying is 162°C, the crystallization time is 30min, the drying temperature is 172°C, and the drying time is 8h; the process temperature of each zone of the extruder for melt extrusion is shown in Table 3; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com