High-nickel-material-based cobalt-magnesium co-doped modified ternary precursor and positive electrode material, and preparation methods therefor

A positive electrode material and co-doping technology, applied in the direction of electrical components, battery electrodes, circuits, etc., to achieve the effects of maintaining stability, reducing mixing, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step (1): Prepare transition metal ion solution with a concentration of 0.5mol L -1 , wherein the nickel-cobalt-magnesium salt is a mixture of nickel sulfate, cobalt sulfate, and magnesium sulfate, and the molar ratio of nickel ions, cobalt ions, and magnesium ions is 0.89:0.05:0.06. The concentration of ammonia water is 2mol L -1 , the concentration of sodium hydroxide is 2mol L -1 The concentration of the mixed solution and sodium hydroxide is 1mol L -1 The solution. Place the above three solutions on a stirrer and stir fully to dissolve the solute completely.

[0034] Step (2): Add 300ml of deionized water to the sealed reaction kettle, and set the stirring speed of the stirring paddle to 650rpm·min -1 , control the temperature of the system at 40°C, drop an appropriate amount of concentrated ammonia water to initially adjust the pH, and then adjust the pH to 10.5 with sodium hydroxide solution. After the system was stabilized, the transition metal ion solution,...

Embodiment 2

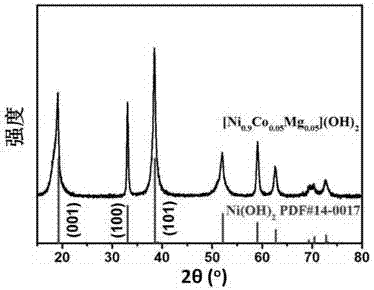

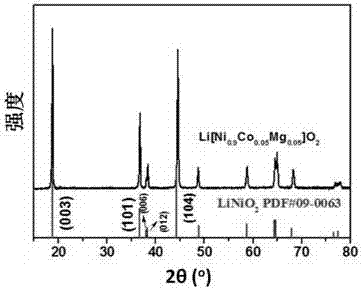

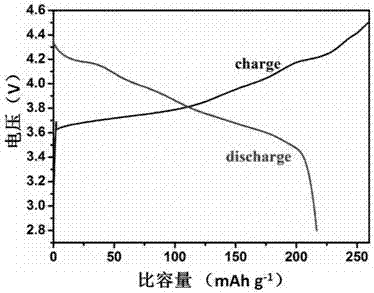

[0038] Step (1): Prepare transition metal ion solution with a concentration of 3mol L -1 , wherein the nickel-cobalt-magnesium salt is a mixture of nickel chloride, cobalt chloride, and magnesium chloride, and the molar ratio of nickel ions, cobalt ions, and magnesium ions is 0.9:0.05:0.05. The concentration of ammonia water is 0.5mol L -1 , the concentration of sodium hydroxide is 0.5mol L -1 The concentration of the mixed solution and sodium hydroxide is 4mol L -1 The solution. Place the above three solutions on a stirrer and stir fully to dissolve the solute completely.

[0039] Step (2): Add 300ml of deionized water to the sealed reaction kettle, and set the stirring speed of the stirring paddle to 800rpm·min -1 , control the temperature of the system at 50°C, drop an appropriate amount of concentrated ammonia water to initially adjust the pH, and then adjust the pH to 10.8 with sodium hydroxide solution. After the system was stabilized, the transition metal ion solut...

Embodiment 3

[0043] Step (1): Prepare transition metal ion solution with a concentration of 1mol L -1 , wherein the nickel-cobalt-magnesium salt is a mixture of nickel sulfate, cobalt sulfate, and magnesium sulfate, and the molar ratio of nickel ions, cobalt ions, and magnesium ions is 0.85:0.1:0.05. The concentration of ammonia water is 3mol L -1 , the concentration of sodium hydroxide is 3mol L -1 The concentration of the mixed solution and sodium hydroxide is 2mol L -1 The solution. Place the above three solutions on a stirrer and stir fully to dissolve the solute completely.

[0044] Step (2): Add 300ml of deionized water to the sealed reaction kettle, and set the stirring speed of the stirring paddle to 750rpm·min -1 , control the temperature of the system at 50°C, drop an appropriate amount of concentrated ammonia water to initially adjust the pH, and then adjust the pH to 10.6 with sodium hydroxide solution. After the system was stabilized, the transition metal ion solution, am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com