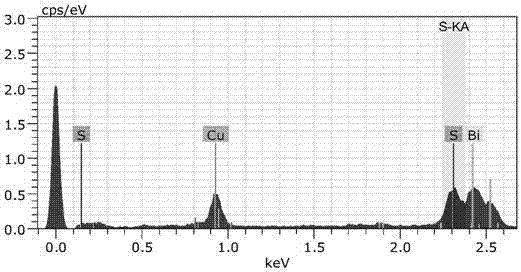

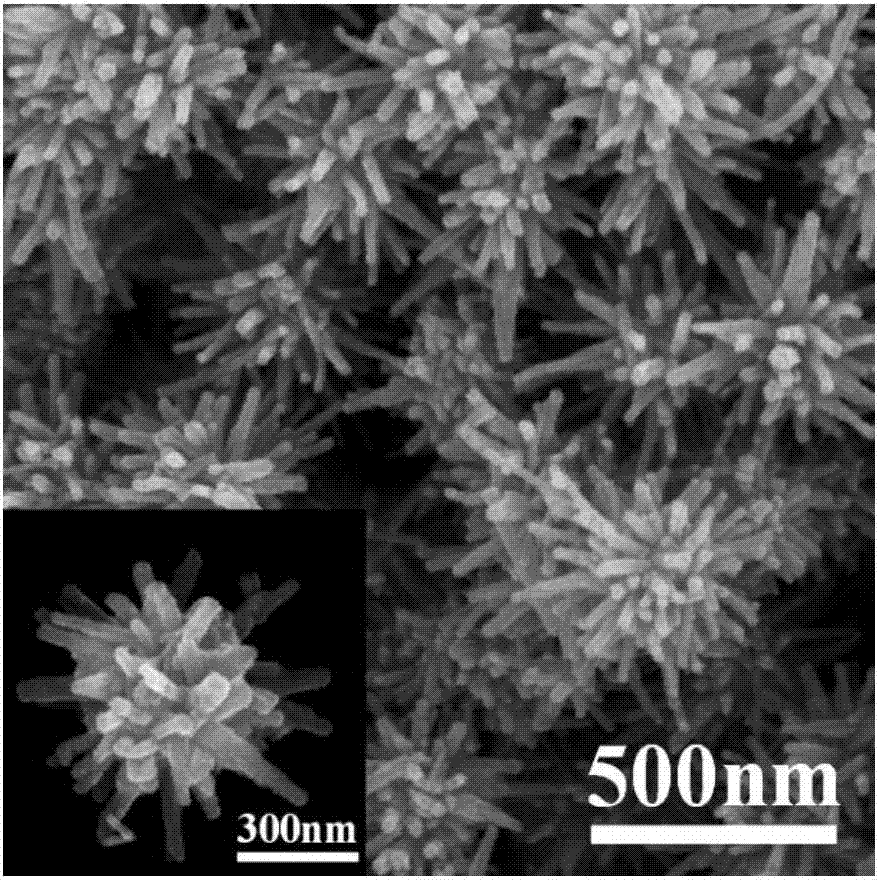

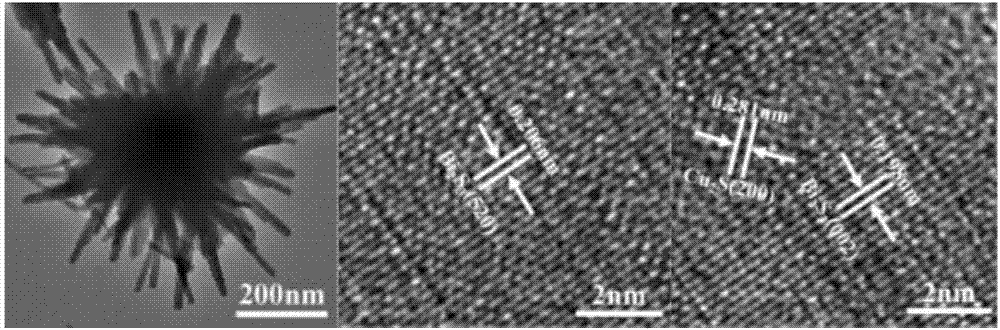

Bismuth sulfide-cuprous sulfide heterojunction composite material with sea urchin-shaped structure, preparation method and application thereof

A composite material, cuprous sulfide technology, used in medical preparations containing active ingredients, wave energy or particle radiation treatment materials, drug combinations, etc. The effect of excellent photothermal performance and huge potential application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a bismuth sulfide-cuprous sulfide heterojunction composite material with a sea urchin structure, comprising the following steps:

[0051] S1: Add 0.1moL copper nitrate, 0.1moL bismuth nitrate and 0.2moL and 0.3moL sodium dimethyldithiocarbamate into pure water respectively, stir well, let stand for 24h, filter and dry to obtain dimethyldithiocarbamate copper carbamate and bismuth dimethyldithiocarbamate;

[0052] S2: In an appropriate amount of organic solvent ethylene glycol, add bismuth dimethyl dithiocarbamate (Bi(DMDC) with a mass ratio of 5:5 3 ) and copper dimethyldithiocarbamate (Cu(DMDC) 2 ), ultrasonically stirred for 10-20min, and mixed evenly to obtain a precursor reaction solution;

[0053] S3: The precursor reaction solution is subjected to a two-stage microwave heating constant temperature reaction, thereby obtaining a bismuth sulfide-cuprous sulfide heterojunction composite material, specifically:

[0054] S3-1: Under the ultraso...

Embodiment 2-3

[0057] Embodiment 2-3: the investigation of raw material consumption ratio

[0058] In addition to using bismuth dimethyl dithiocarbamate (Bi(DMDC) in different molar ratios shown in the following table 1 in step S1 3 ) and copper dimethyldithiocarbamate (Cu(DMDC) 2 ), other operations are all identical to embodiment 1, thereby carried out embodiment 2-3, used raw material consumption ratio and composite material nomenclature see table 1 below.

[0059] Table 1. Composite materials prepared under different raw material dosage ratios

[0060]

Embodiment 4-6

[0061] Embodiment 4-6: the investigation of ultrasonic stirring power

[0062] Embodiment 4-6: Except using the ultrasonic stirring power shown in table 2 below in step S3-2 and S3-3, other operations are all the same as embodiment 1, thereby carried out embodiment 4-6, the ultrasonic stirring power used The stirring power and composite material nomenclature are shown in Table 2 below.

[0063] Table 2. Composite materials prepared under different ultrasonic stirring power

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com