Preparing method of magnetic carbon composite adsorption material

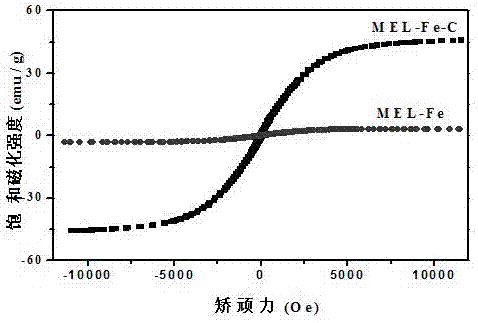

A technology of composite adsorbent material and magnetic material, applied in the field of composite material technology and water treatment, can solve the problem that adsorbent is not easy to recover, and achieve the effects of good recycling performance, many recycling times, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

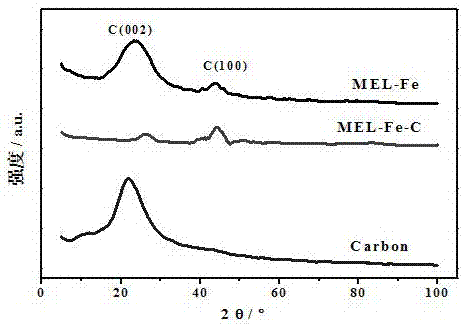

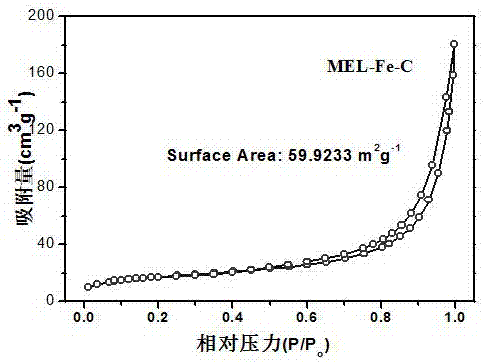

Image

Examples

Embodiment 1

[0035] Add 10g of ammonium polyphosphate to 300mL of tetrahydrofuran and mix evenly; then ultrasonically disperse 10g of graphite powder into it to obtain a mixed suspension; dissolve 0.6g of ferric sulfate in 200mL of tetrahydrofuran and add it to the above-mentioned The mixed suspension was obtained, heated to 80°C and stirred for 8 hours, then suction filtered, and the obtained mixture was first dried in an oven for 12 hours to obtain a mixture powder; then the mixture powder was placed in a tube furnace, and treated at 600°C under the protection of argon 6 hours (heating rate: 5°C / min), then fully ground and sieved with 200 mesh to obtain 20.6g magnetic carbon composite adsorption material. The removal rate of methylene blue by this adsorbent material can reach about 92% for the first time, and the removal rate remains above 50% after repeated use for 15 times.

Embodiment 2

[0037] Add 2g of urea into 100mL of methanol and mix evenly, then ultrasonically disperse 8g of activated carbon into it to obtain a mixed suspension; dissolve 10g of cobalt chloride into 100mL of methanol and add it to the above mixing In the suspension, heat to 30°C and stir for 8 hours, filter with suction, and dry the mixture in an oven for 8 hours, then place it in a tube furnace, and treat it at 1000°C for 6 hours under the protection of nitrogen (the heating rate is 20°C / min), After that, it was fully ground and sieved with 100 mesh to obtain 20 g of magnetic carbon composite adsorption material. The adsorption material can remove about 95% of the acid blue for the first time, and the removal rate remains above 45% after repeated use for 15 times.

Embodiment 3

[0039] Add 5g of bipyridinium ammonium into 100mL of hot water and mix evenly; then ultrasonically disperse 8g of carbon nanotubes into it to obtain a mixed suspension; put 10g of magnetic CeCo 3 Disperse in 100mL of water and add it to the above mixed suspension under ultrasonic conditions; heat to 70°C and stir for 5 hours, filter with suction, and dry the obtained mixture in an oven for 5 hours, then place it in a tube furnace under nitrogen protection Treat at 500°C for 4 hours (heating rate: 1°C / min), then fully grind, and sieve through 150 mesh to obtain 16g of magnetic carbon composite adsorption material. The adsorption material can remove about 90% of the acid blue for the first time, and the removal rate remains above 50% after repeated use for 12 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com