Ultrafine ptrh nanowire and its catalyst preparation method and application

A nanowire and catalyst technology, applied in the field of precious metal nanocatalysts, can solve the problems such as the rapid preparation of Pt ultrafine nanowires that has not been reported yet, and achieve the effects of high catalytic activity and catalytic stability, stability improvement, and quality activity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

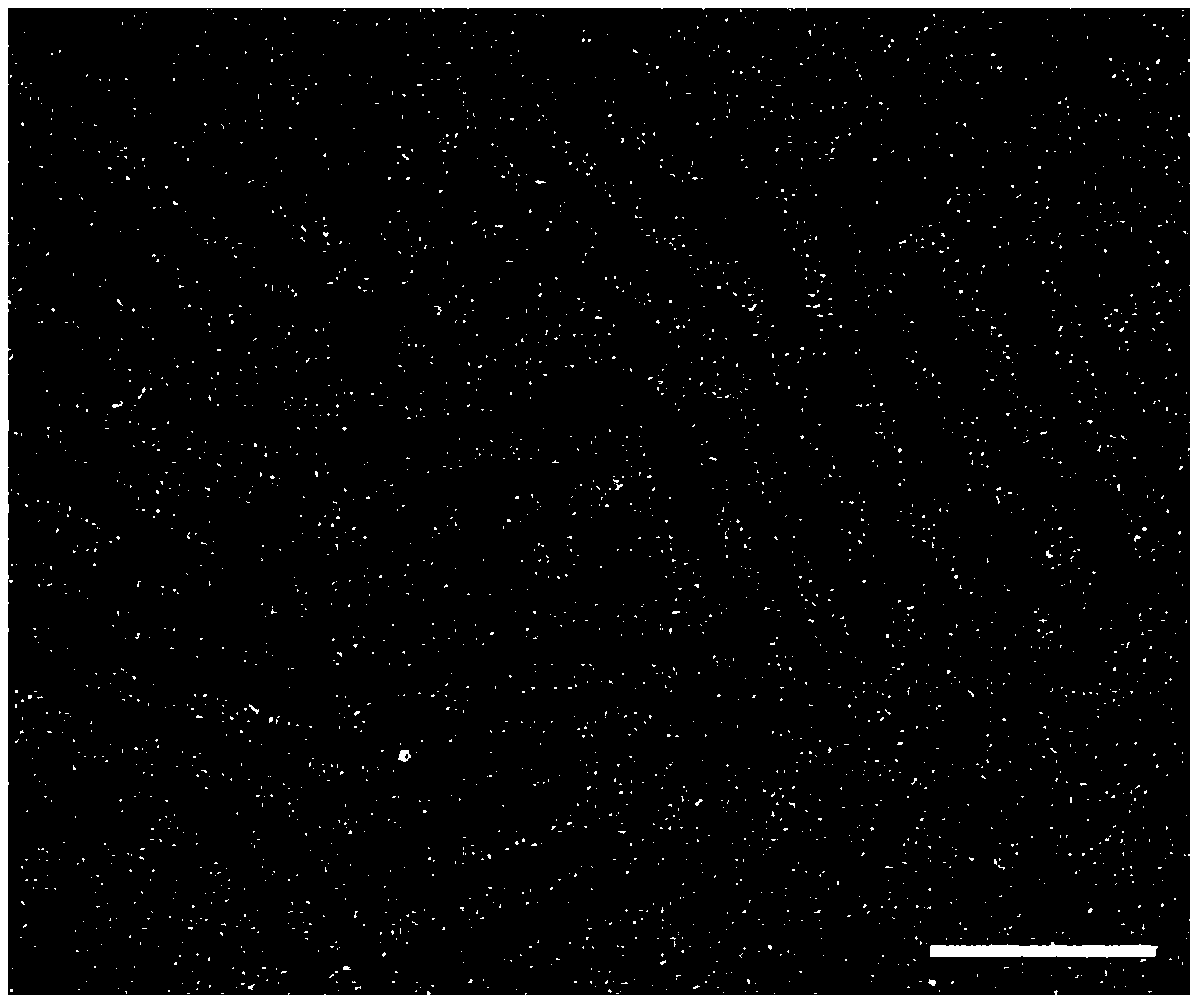

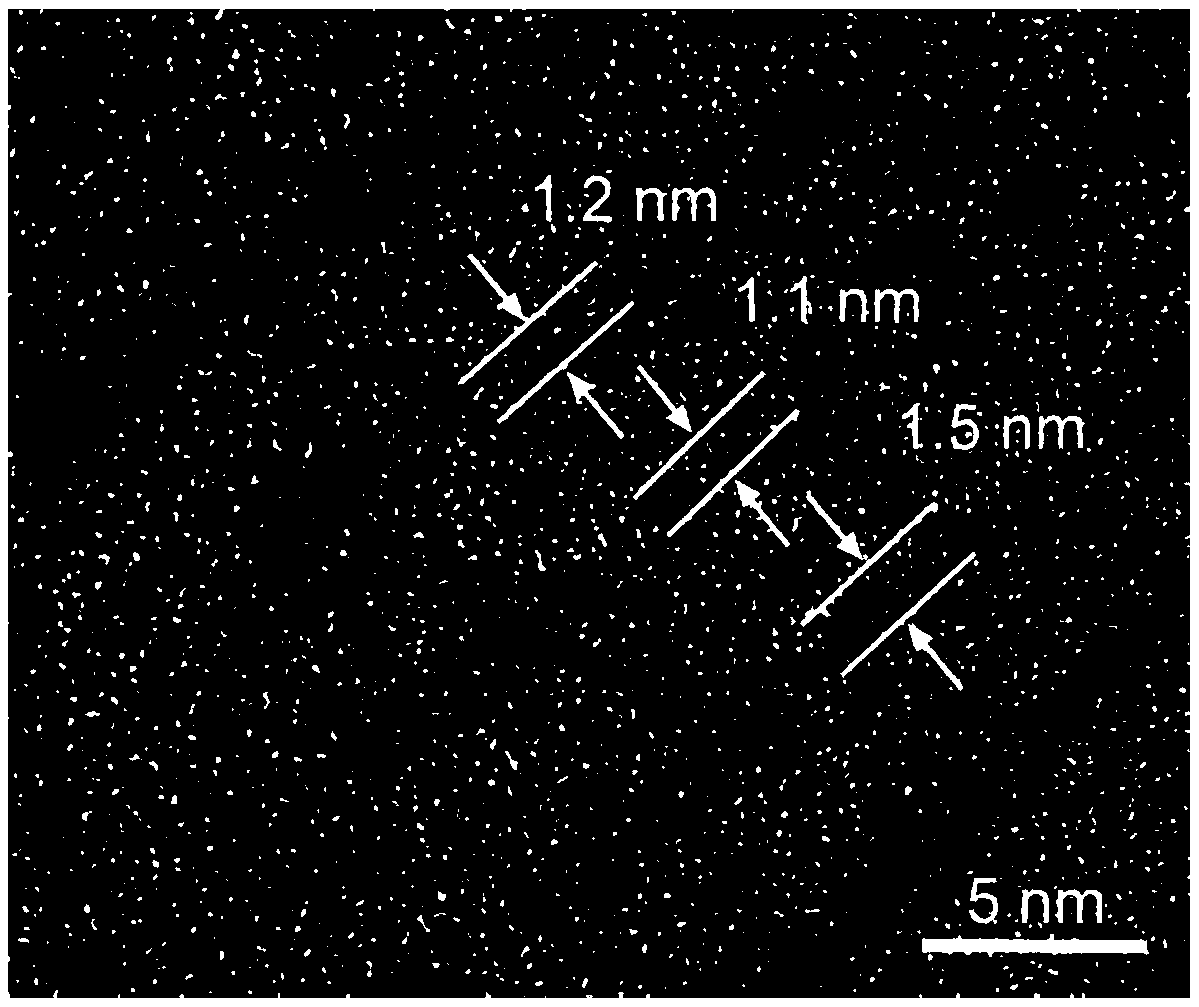

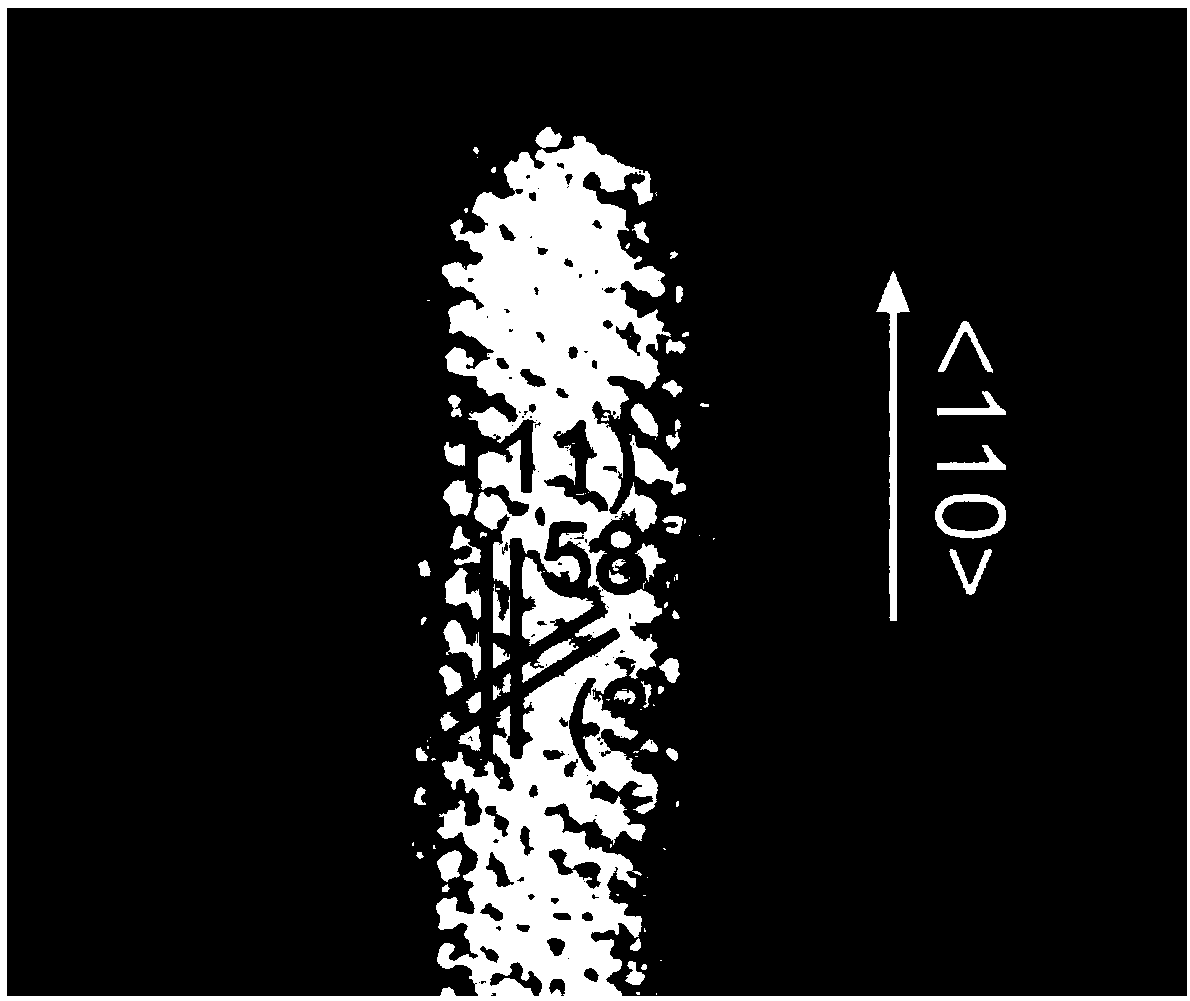

[0043] A kind of preparation method of the superfine PtRh nanowire that the present invention proposes, successively add platinum acetylacetonate, rhodium acetylacetonate and didodecyl dimethyl ammonium bromide in oleylamine and carry out ultrasonic treatment to obtain mixed solution; Add tungsten carbonyl to the mixture, raise the temperature to carry out high-temperature reaction, cool to room temperature, wash, and dry to obtain ultrafine PtRh nanowires.

[0044] A kind of preparation method of PtRh / C metal nano-catalyst that the present invention proposes, the hexane solution containing above-mentioned superfine PtRh nanowire is slowly injected in the hexane solution of carbon black to obtain solution A, ultrasonic treatment, cleaning, drying obtains PtRh / C C metal nanocatalysts.

Embodiment 2

[0046]The preparation method of a kind of superfine PtRh nano wire that the present invention proposes, successively add platinum acetylacetonate, rhodium acetylacetonate and didodecyl dimethyl ammonium bromide in oleylamine and ultrasonically treat for 0.4h to obtain a mixed solution, acetylacetonate The mass volume ratio (mg / mL) of platinum and oleylamine is 30:4.8, the mass volume ratio (mg / mL) of rhodium acetylacetonate and oleylamine is 3.5:4.8, didodecyldimethylammonium bromide and The mass-volume ratio (mg / mL) of oleylamine is 95:4.8; add tungsten carbonyl to the mixture, the mass-volume ratio (mg / mL) of tungsten carbonyl and oleylamine is 11:4.8, heat up for high-temperature reaction, high-temperature reaction The temperature is 185°C, the high-temperature reaction time is 1.5hh, cooled to room temperature, and the material after cooling to room temperature is centrifuged, the speed of centrifugation is 16000 rpm, and the time of centrifugation is 5min. The non-polar s...

Embodiment 3

[0049] The preparation method of a kind of ultrafine PtRh nanowire that the present invention proposes, successively add platinum acetylacetonate, rhodium acetylacetonate and didodecyl dimethyl ammonium bromide into oleylamine and ultrasonically treat for 0.6h to obtain a mixed solution, acetylacetonate The mass volume ratio (mg / mL) of platinum and oleylamine is 28:5.2, the mass volume ratio (mg / mL) of rhodium acetylacetonate and oleylamine is 2.7:5.2, didodecyldimethylammonium bromide and The mass-volume ratio (mg / mL) of oleylamine is 85:5.2; add tungsten carbonyl to the mixture, the mass-volume ratio (mg / mL) of tungsten carbonyl and oleylamine is 9:5.2, and heat up for high-temperature reaction. The temperature is 175°C, the high temperature reaction time is 2.5h, cooled to room temperature, and the material after cooling to room temperature is subjected to centrifugation, the speed of centrifugation is 15000 rpm, and the time of centrifugation is 7min, and the centrifuged pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com