Preparation method of high-strength and ultra-high temperature resistant zirconia fiberboard or special-shaped parts

A technology of zirconia fiber and special-shaped parts, which is applied in the field of ultra-high temperature heat insulation and energy-saving materials, which can solve the problems of easy deformation, cracking or even pulverization of fiberboard, high risk, wide distribution of fiber diameters, etc., and achieve excellent high temperature mechanics and heat insulation performance, high compressive strength, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

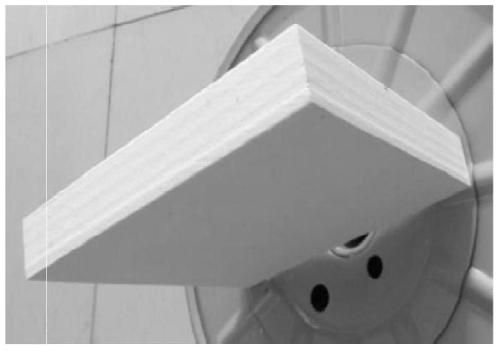

[0037] Example 1: Preparation of high-strength ultra-high temperature resistant zirconia fiberboard

[0038] (1), pulping. Weigh basic zirconium carbonate and glacial acetic acid according to the molar ratio of basic zirconium carbonate: glacial acetic acid as 1:2.2, slowly add glacial acetic acid to basic zirconium carbonate powder, and wait until the reaction is completely stirred to form a transparent solution. than Y 2 o 3 :( 2 o 3 +ZrO 2 ) = 8mol% mixed with yttrium nitrate hexahydrate, stirred and dissolved to form polyzirconyl acetate sol; polyzirconyl acetate sol was mixed with water evenly according to the volume ratio of 1:2, and the resulting mixed solution was used to make zirconia fiberboard Binder for special-shaped parts; chopped zirconia fibers sintered to 1200°C with a diameter of 4μm-5μm to 1-3mm, and then added to the above mixed solution binder, the weight of zirconia fibers is bonded with the mixed solution The weight ratio of the agent is 1:50, mix ...

Embodiment 2

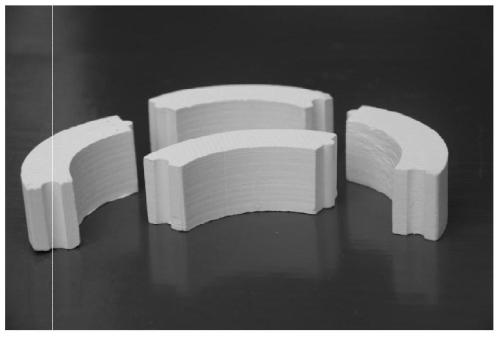

[0042] Example 2: Preparation of high-strength ultra-high temperature resistant zirconia fiber profiled parts

[0043] As described in Example 1, the difference is that in step (2), the suspension is poured into the special-shaped part mold, and the special-shaped part mold is a curved plate mold with butt joint bumps at both ends, which are suitable for the shape of the product. Vacuum filter to remove excess water, then pressurize and filter, and recycle the excess solution to obtain zirconia fiber shaped parts, such as figure 2 shown. The obtained product is tested, and the purity is 99.8%, and the product density is 350Kg / m 3 , Under the condition of 2200℃X12h, the linear shrinkage rate is 1%, and the dimensional change rate is less than 1%. The zirconia fiber profiled part is butted into a ring shape and can be used as a thermal insulation part of a crystal growth furnace.

Embodiment 3

[0045] As described in Example 1, the difference is that in step (1), the polyzirconyl acetate sol is uniformly mixed with water at a volume ratio of 1:5, and the resulting mixed solution is used as a binder for making zirconia fiberboards and special-shaped parts . The resulting zirconia fiberboard has been tested and found to have a purity of 99.8% and a bulk density of 300Kg / m 3 , the compressive strength at room temperature is 2.8MPa, and the shrinkage rate is 1.2% at 2200°C X12h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com