Calcium copper titanate (CCTO)/polydimethylsiloxane (PDMS) composite flexible foam as well as preparation method and application thereof

A technology of dimethyl siloxane and copper calcium titanate, which is applied in fluid pressure measurement, instruments, and measuring devices using capacitance changes, and can solve problems such as low sensitivity of pressure sensors, insufficient elasticity and flexibility, and complex production processes , to achieve the effects of excellent mechanical properties, improved sensitivity, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A copper calcium titanate / polydimethylsiloxane composite flexible foam, comprising the following components in parts by weight: 10 parts of PDMS precursor, 1.5 parts of dimethyl silicone oil, 0.1 part of CCTO powder, and silane coupling agent KH5500 .005 parts, 1 part dimethylmethylhydrogensiloxane, 17 parts sucrose powder, and 5 parts ethanol.

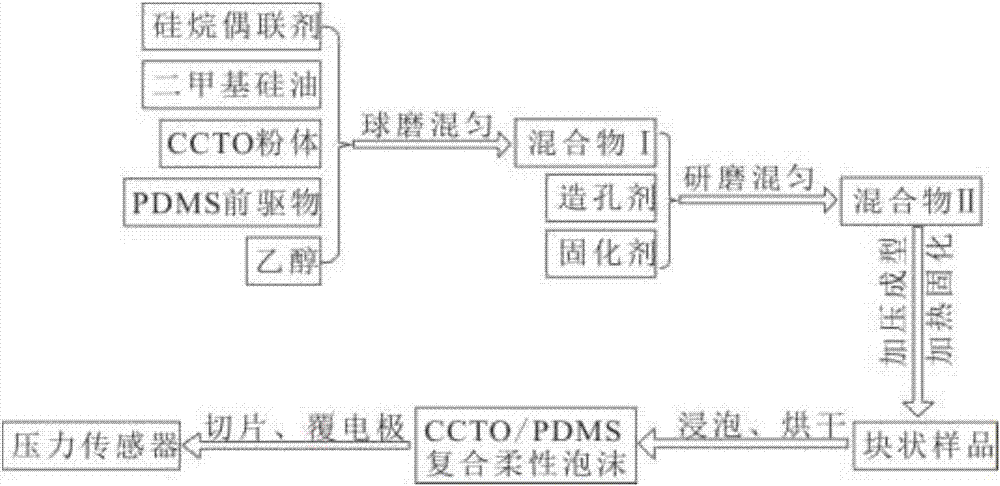

[0033] The preparation method of above-mentioned calcium copper titanate / polydimethylsiloxane composite flexible foam comprises the following steps:

[0034] (1) According to the formula, mix CCTO powder, PDMS precursor, dimethyl silicone oil, ethanol, and silane coupling agent KH550 evenly, put them in a ball mill jar and mill them for 20 minutes to obtain mixture I; among them, the particle size of CCTO powder is 220nm ;

[0035] (2) Add dimethylmethylhydrogensiloxane and sucrose powder with a particle size of 110 μm to mixture I, and continue grinding for 20 minutes to obtain mixture II;

[0036] (3) Put the mixture II in ...

Embodiment 2

[0040] A copper calcium titanate / polydimethylsiloxane composite flexible foam, comprising the following components in parts by weight: 10 parts of PDMS precursor, 1.5 parts of dimethyl silicone oil, 0.3 parts of CCTO powder, and silane coupling agent KH5500 .01 parts, 1 part dimethylmethylhydrogensiloxane, 17 parts sucrose powder, and 8 parts ethanol.

[0041] The preparation method of above-mentioned calcium copper titanate / polydimethylsiloxane composite flexible foam comprises the following steps:

[0042] (1) According to the formula, mix CCTO powder, PDMS precursor, dimethyl silicone oil, ethanol, and silane coupling agent KH550 evenly, and place them in a ball mill jar for ball milling for 30 minutes to obtain mixture I; among them, the particle size of CCTO powder is 400nm ;

[0043] (2) Add dimethylmethylhydrogensiloxane and sucrose powder with a particle size of 110 μm to mixture I, and continue grinding for 35 minutes to obtain mixture II;

[0044] (3) Put the mixtu...

Embodiment 3

[0048] A copper calcium titanate / polydimethylsiloxane composite flexible foam, comprising the following components in parts by weight: 10 parts of PDMS precursor, 1.5 parts of dimethyl silicone oil, 0.5 parts of CCTO powder, and silane coupling agent KH5500 .025 parts, 1 part dimethyl methylhydrogen siloxane, 17 parts sucrose powder, and 10 parts ethanol.

[0049] The preparation method of above-mentioned calcium copper titanate / polydimethylsiloxane composite flexible foam comprises the following steps:

[0050] (1) According to the formula, mix CCTO powder, PDMS precursor, dimethyl silicone oil, ethanol, and silane coupling agent KH550 evenly, and put them in a ball mill jar for ball milling for 28 minutes to obtain mixture I; among them, the particle size of CCTO powder is 340nm ;

[0051] (2) Add dimethylmethylhydrogensiloxane and sucrose powder with a particle size of 90 μm to mixture I, and continue grinding for 35 minutes to obtain mixture II;

[0052] (3) Put the mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com