Alkylation method and device for isobutane and C3-C5 olefins

An isobutane and alkylation technology, which is applied in the treatment of hydrocarbon oil, liquid hydrocarbon mixture production, petroleum industry, etc., can solve the problems of untimely withdrawal of reaction heat, unfavorable alkylation reaction, etc. The effect of catalyst consumption and prevention of system temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

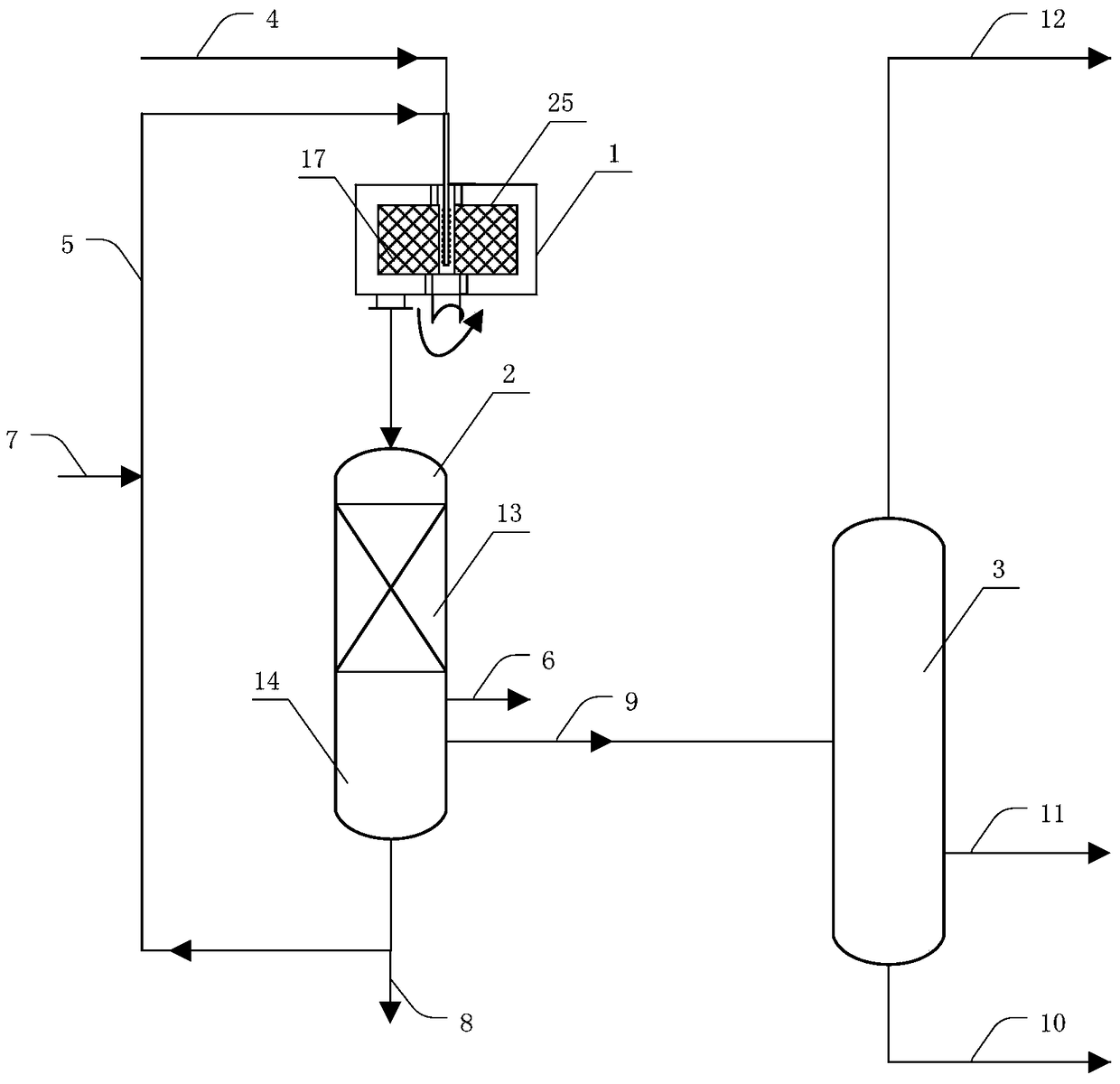

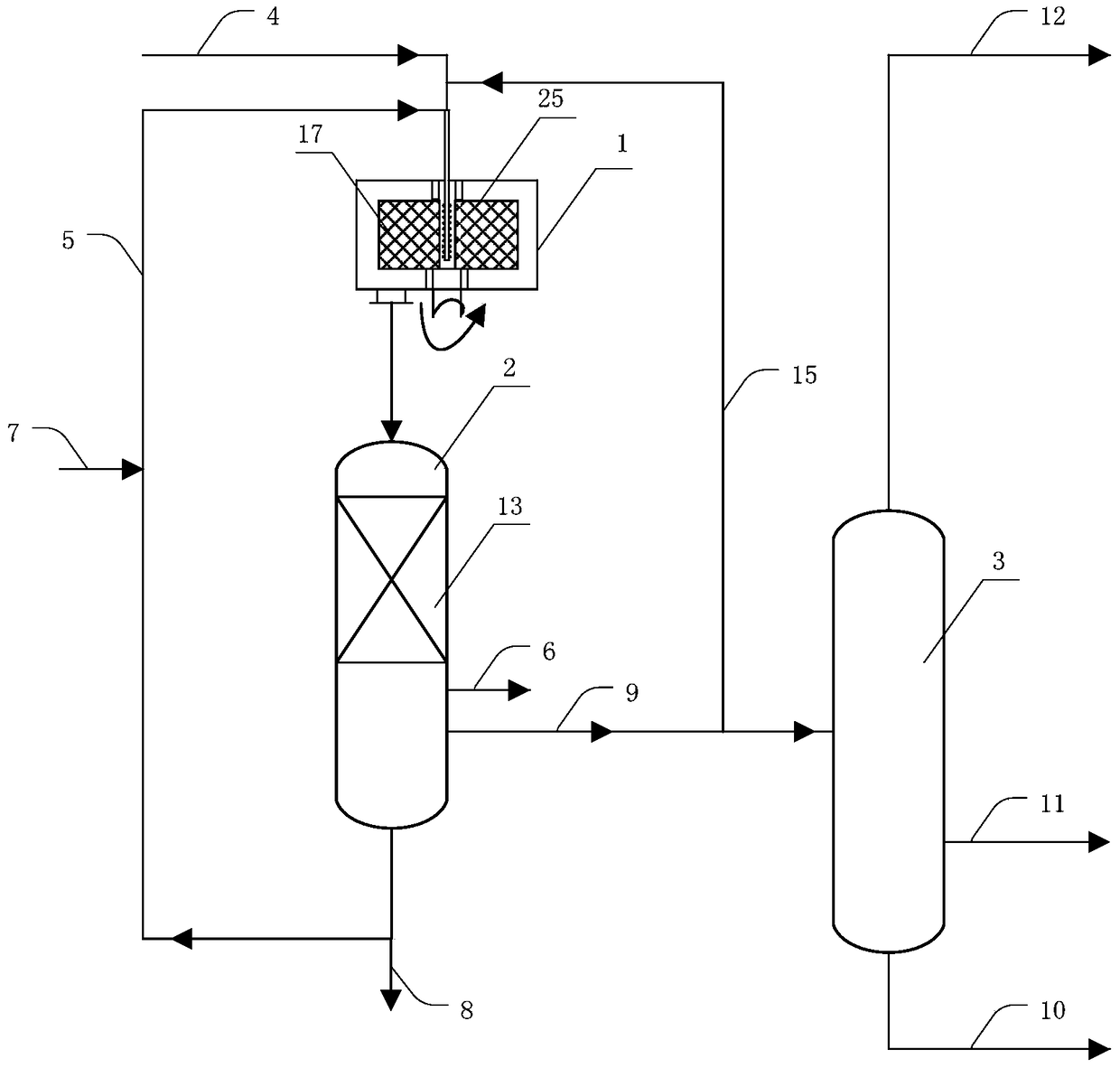

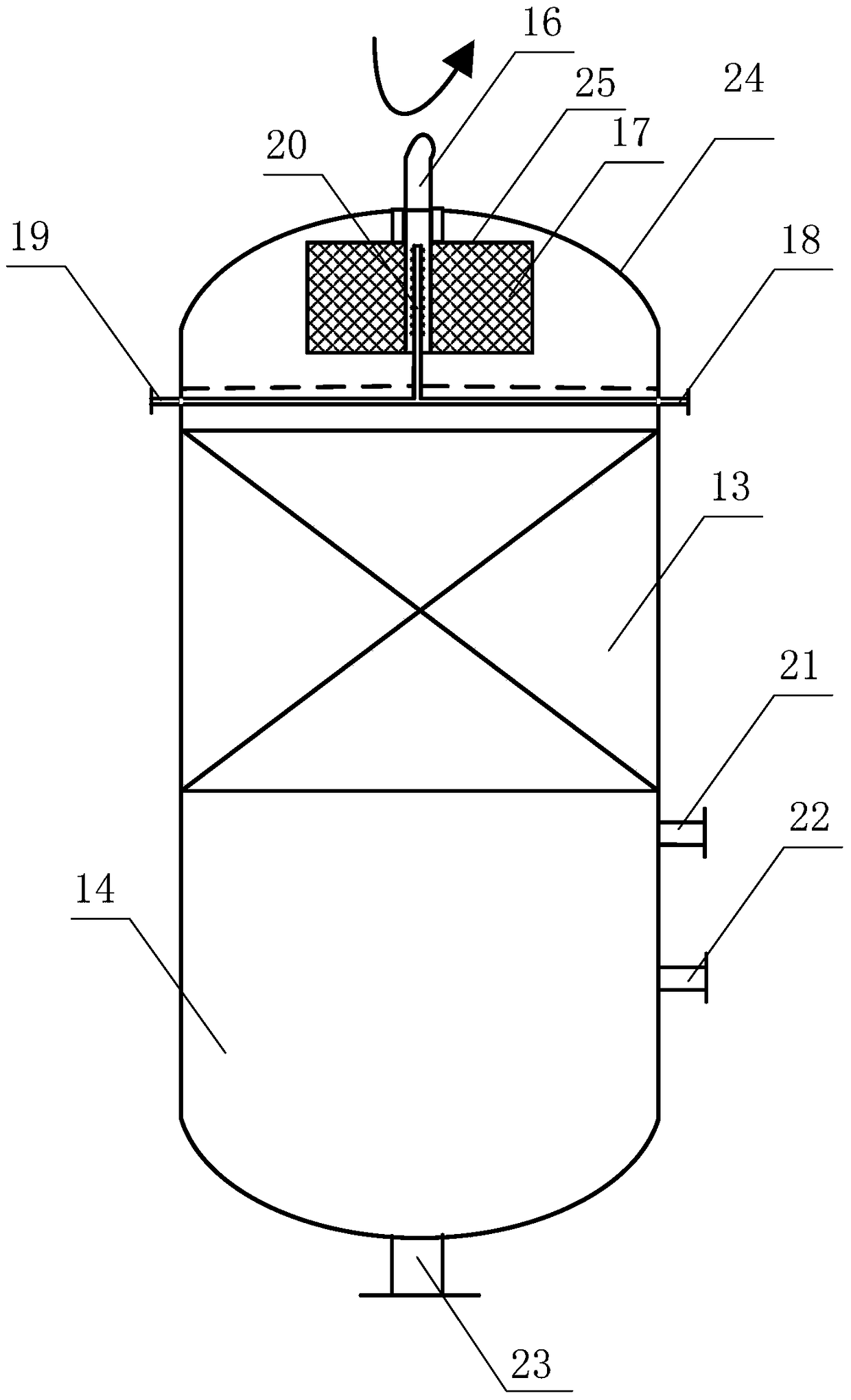

[0027] see figure 1 As shown, the reaction device of the present invention includes: a rotating packed bed reactor 1 , a packed bed reactor 2 and a distillation column 3 . The packed bed reactor 2 is divided into a packing reaction section 13 and a settling section 14 up and down.

[0028] The raw material and the liquid alkylation catalyst enter the rotary packed bed reactor 1 through the feeding pipe 4 and the catalyst circulation pipe 5 respectively, and the alkylation reaction starts in the packing layer of the rotary packed bed reactor 1 . The raw material and liquid alkylation catalyst are thrown out of the rotating packed bed reactor 1 under the action of centrifugal force when the packing layer of the rotating packed bed reactor 1 rotates, and unreacted raw materials, products and liquid alkanes are formed at the outlet of the rotating packed bed reactor 1. The reaction material mixed with the base catalyst, the reaction material flows into the packed bed reactor 2, c...

Embodiment 2

[0031] The operation mode and operation process are the same as in Example 1, the catalyst is sulfuric acid with a mass concentration of 99.8%, the molar ratio of isobutane to olefin in the raw material is 10:1, and the average residence time of the reaction materials in the packing reaction section 13 is 60min. The filler used in the packed bed reactor 2 is a Pall ring. The reaction material is continuous in the gas phase in the packing reaction section 13, the reaction temperature is controlled at -5°C, the rotor speed of the rotary packed bed reactor 1 is controlled at 2500rpm, and the volume ratio of liquid hydrocarbons to sulfuric acid in the reaction system is 1:1. The octane number of the obtained alkylate was 98.1 (research octane number), and the catalyst consumption was 31 kg / (t alkylate).

Embodiment 3

[0033] The operation mode and operation process are the same as in Example 1, the catalyst is sulfuric acid with a mass concentration of 89%, the molar ratio of isobutane to olefin in the raw material is 300:1, and the average residence time of the reaction materials in the packing reaction section 13 is 1min. The packing used in the packed bed reactor 2 is corrugated net packing. The reaction temperature was controlled at 20° C., the rotational speed of the rotor of the rotary packed bed reactor 1 was controlled at 100 rpm, and the volume ratio of liquid hydrocarbons to sulfuric acid in the reaction system was 3:1. The octane number of the obtained alkylate was 98.9 (research octane number), and the catalyst consumption was 21 kg / (t alkylate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com