Preparation method for lamellar porous biocarbon with good adsorption function

A technology of biochar and strong adsorption, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as easy migration, great harm, and difficult to degrade, so as to reduce the degree of non-point source pollution and greatly The effect of enhancing adsorption performance and pollutant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

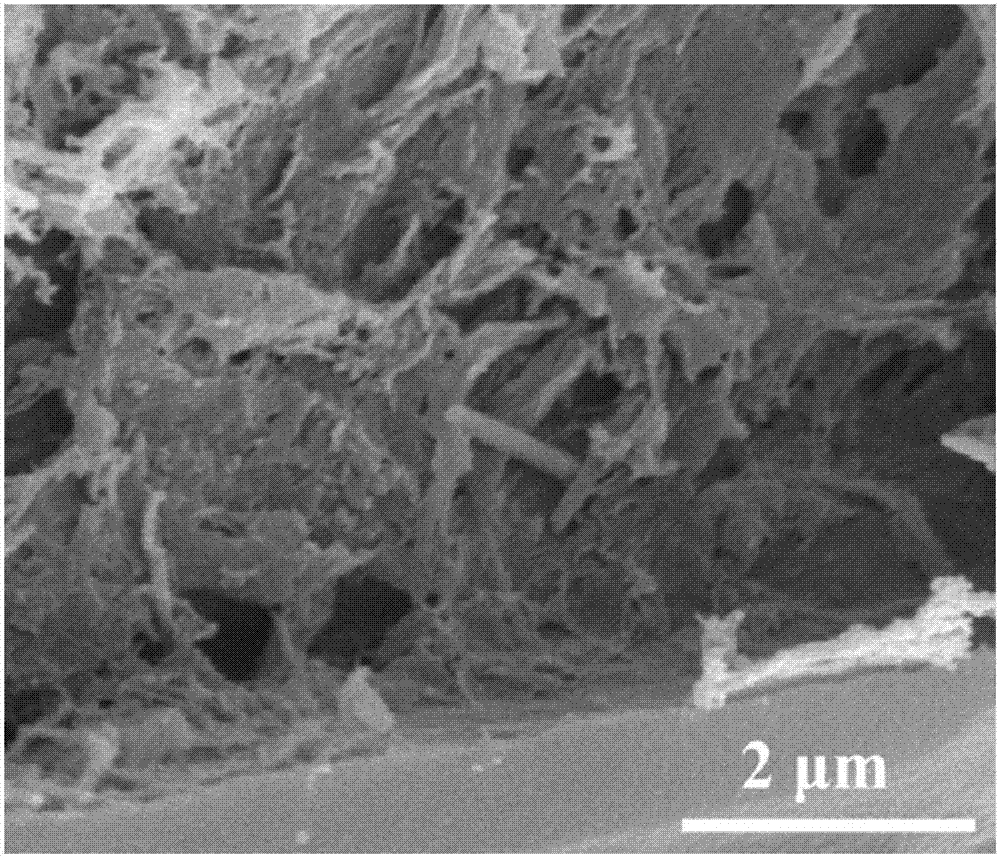

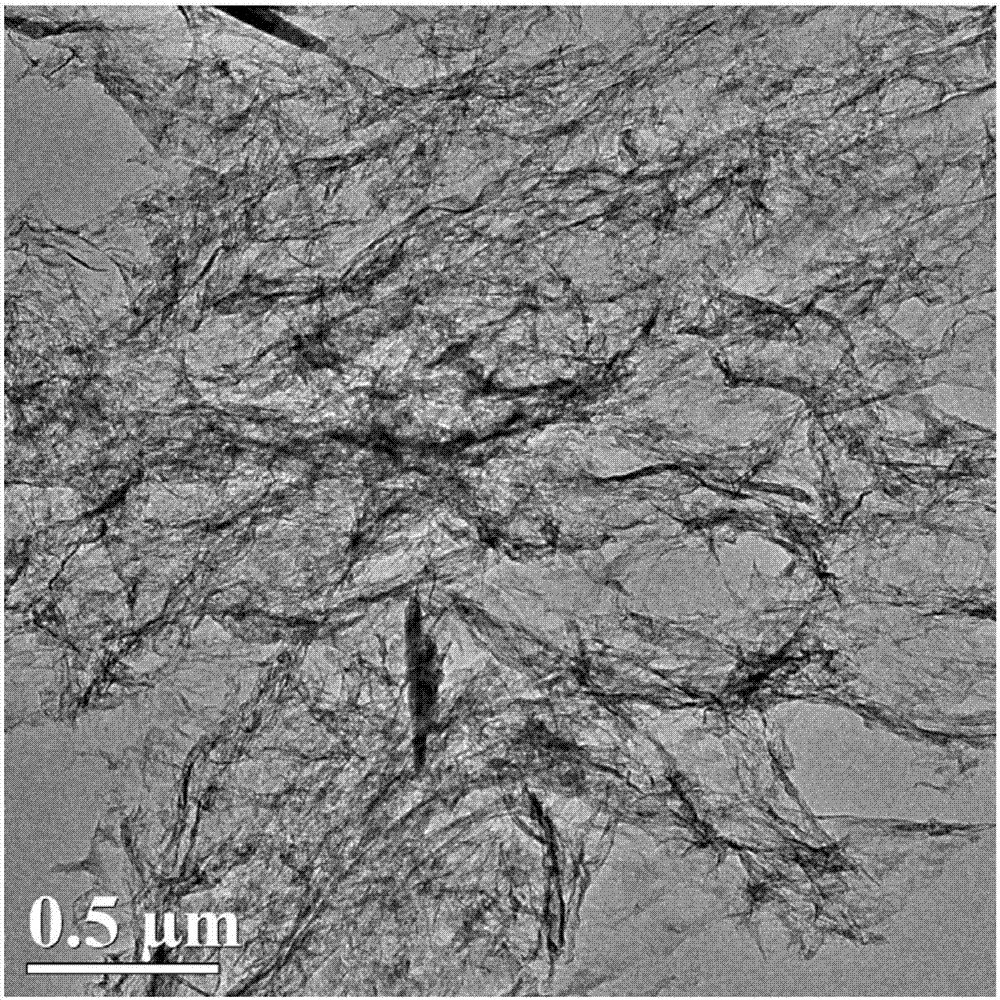

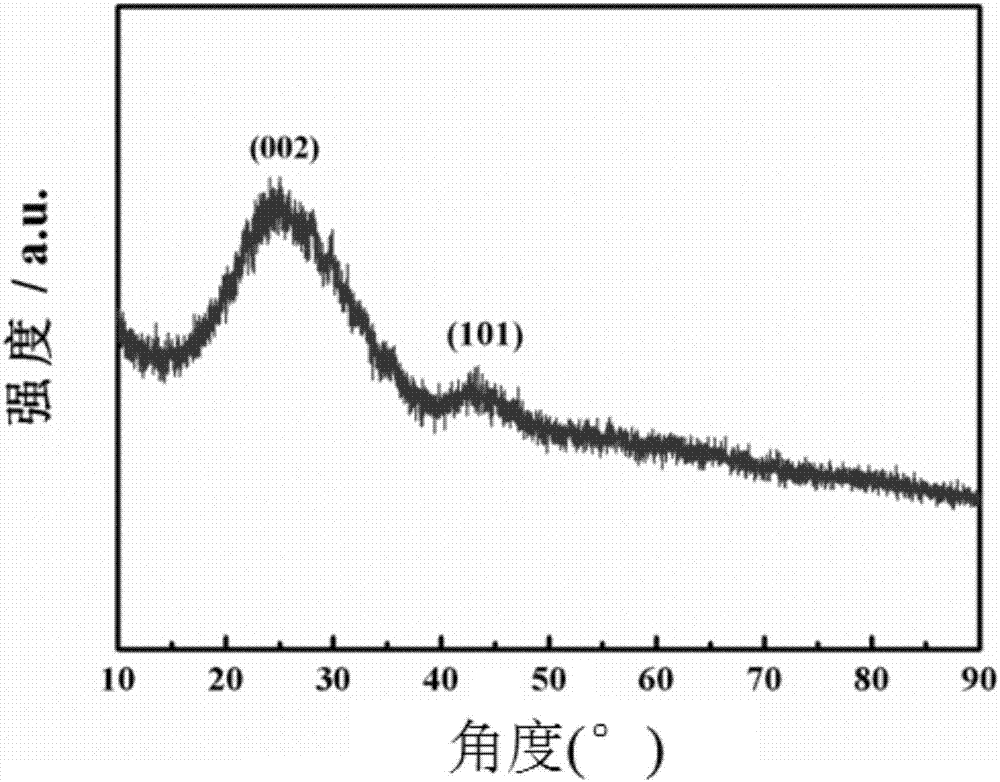

[0024] Embodiment 1: This embodiment is a preparation method of sheet-layer porous biochar with strong adsorption function, which is characterized in that the method is specifically completed according to the following steps:

[0025] 1. Cleaning:

[0026] Use distilled water to wash the waste biomass 3 to 5 times, then dry it in a constant temperature drying oven at a temperature of 60°C to 100°C for 2h to 8h, then crush the waste biomass and sieve to obtain biomass powder;

[0027] 2. Preparation of biochar:

[0028] Mix the biomass powder with the low-melting point molten salt containing chlorine atoms evenly to obtain the mixture; then put the mixture into the vacuum tube furnace under the protection of inert gas, and then set the vacuum tube furnace at a temperature of 5°C / min to 15°C / min The heating rate is raised to 650°C~1000°C, and then heated at 650°C~1000°C for 2h~6h, and finally the vacuum tube furnace is naturally cooled to room temperature to obtain the reaction...

specific Embodiment approach 2

[0036]Embodiment 2: This embodiment differs from Embodiment 1 in that the waste biomass described in step 1 is sawdust, crop straw, rice husk, municipal solid waste, sludge or livestock manure. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the biomass powder in step 1 is 100 mesh to 300 mesh. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com