Method for scale rapid preparation of perovskite semiconductor material

A perovskite and semiconductor technology, applied in the field of large-scale and rapid preparation of perovskite semiconductor materials, can solve the problems of difficult removal of structure-inducing reagents, difficult control of particle size, low purity and yield, etc., and achieve clean and pollution-free reaction routes , easy large-scale preparation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A large-scale and rapid preparation of perovskite semiconductor material Cs 4 PbBr 6 method, the specific steps are as follows:

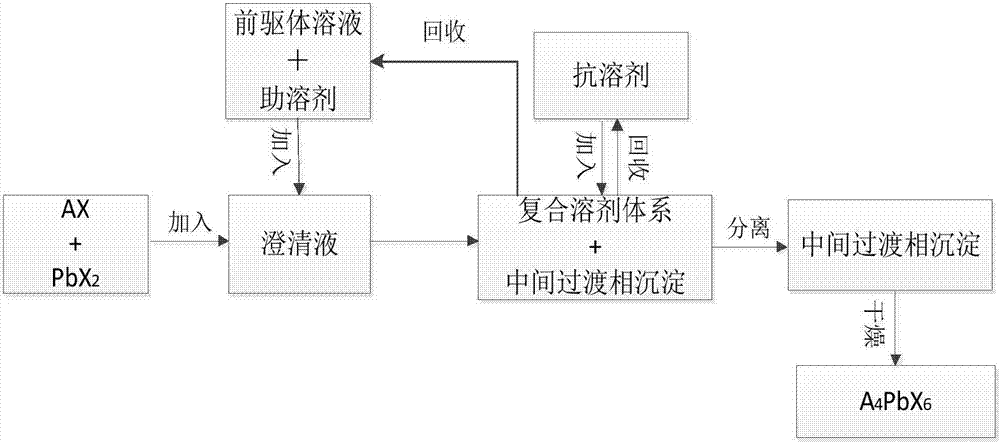

[0024] Such as figure 1 shown, using PbBr 2 , CsBr , NH 4 Br as PbX 2 , AX and co-solvent, dimethyl sulfoxide as precursor solution, chloroform as anti-solvent, 1 mol PbBr 2 , 4 mol CsBr dissolved in 20 L containing 2 mol NH 4 Br in the dimethyl sulfoxide solution, stirred until the solution was completely clear to obtain a clear liquid, then quickly added chloroform with the same volume as the clear liquid, and stirred at the same time, a white intermediate transition phase precipitate was generated in the system, and then centrifuged, the solvent Recycled into the next cycle of production, the obtained intermediate transition phase precipitate was dried at a constant temperature of 60 °C for 1 hour to obtain yellow-green Cs 4 PbBr 6 powder, the yield reaches 100%, and the quantum yield reaches 90%.

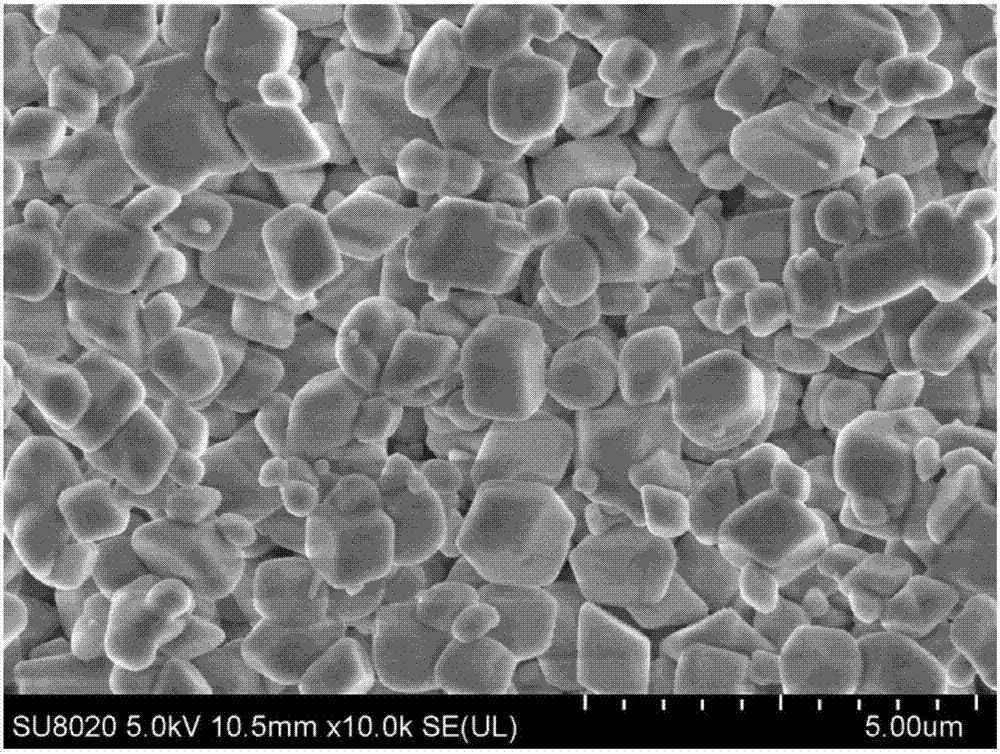

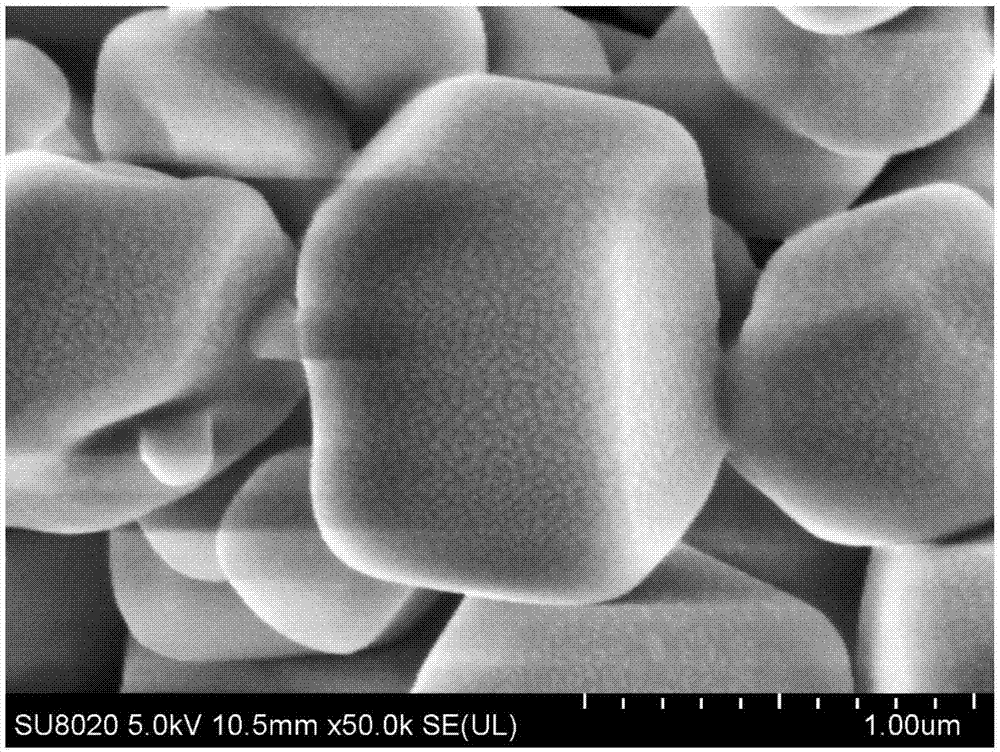

[0025] figure 2 It is the SE...

Embodiment 2

[0027] A large-scale and rapid preparation of perovskite semiconductor material Cs 4 PbBr 6 method, the specific steps are as follows:

[0028] Such as figure 1 shown, using PbBr 2 , CsBr, HBr as PbX 2 , AX and co-solvent, dimethyl sulfoxide as precursor solution, chloroform as anti-solvent, 1 mol PbBr 2 , 0.5 mol CsBr was dissolved in 5 L of dimethyl sulfoxide solution containing 2 mol HBr, stirred until the solution was completely clear to obtain a clear liquid, then quickly added chloroform with the same volume as the clear liquid, while stirring, the system formed The white precipitate was then centrifuged, and the solvent was recovered for use in the next cycle of production. The obtained white precipitate was kept at 60 °C for 1 hour to obtain yellow-green Cs 4 PbBr 6 powder and white PbBr 2 Powder mixture, PbBr removed with DMSO 2 powder to give yellow-green Cs 4 PbBr 6 , the yield was 40%, and the quantum yield reached 30%.

Embodiment 3

[0030] A large-scale and rapid preparation of perovskite Cs 4 PbBr 6 method, the specific steps are as follows:

[0031] Such as figure 1 shown, using PbBr 2 , CsBr as PbX 2 , AX, HBr as co-solvent, DMSO as precursor solution, chloroform as anti-solvent, 1 mol PbBr 2 10 mol CsBr was dissolved in 25 L of dimethyl sulfoxide solution containing 2 mol HBr, stirred until the solution was completely clear to obtain a clear liquid, then quickly added chloroform with the same volume as the clear liquid, while stirring, the system formed The white precipitate was then centrifuged, and the solvent was recovered for use in the next cycle of production. The obtained white precipitate was kept at 60 °C for 1 hour to obtain yellow-green Cs 4 PbBr 6 Mixed powder with white CsBr, Cs 4 PbBr 6 The yield rate was 20%, and the quantum yield reached 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com