Organic silicone modified polyurethane/epoxy/acrylate composite emulsion and preparation method thereof

A technology of acrylate and composite emulsion, applied in the direction of coating, etc., can solve the problems of poor modification effect of epoxy addition, incomplete ring opening of epoxy groups, and reduced emulsion stability, and achieve excellent centrifugal stability , Excellent weather resistance, and the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

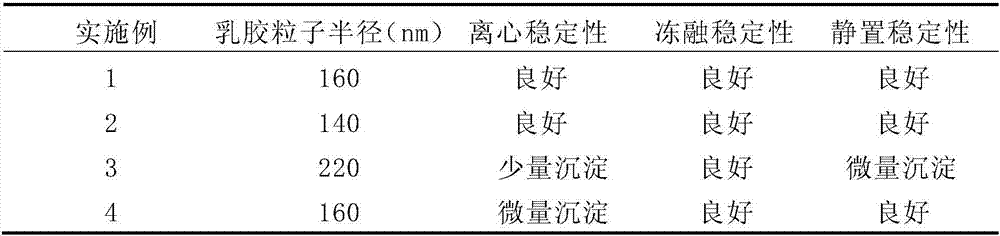

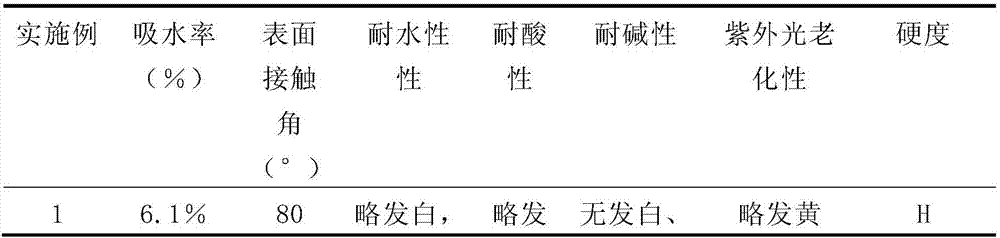

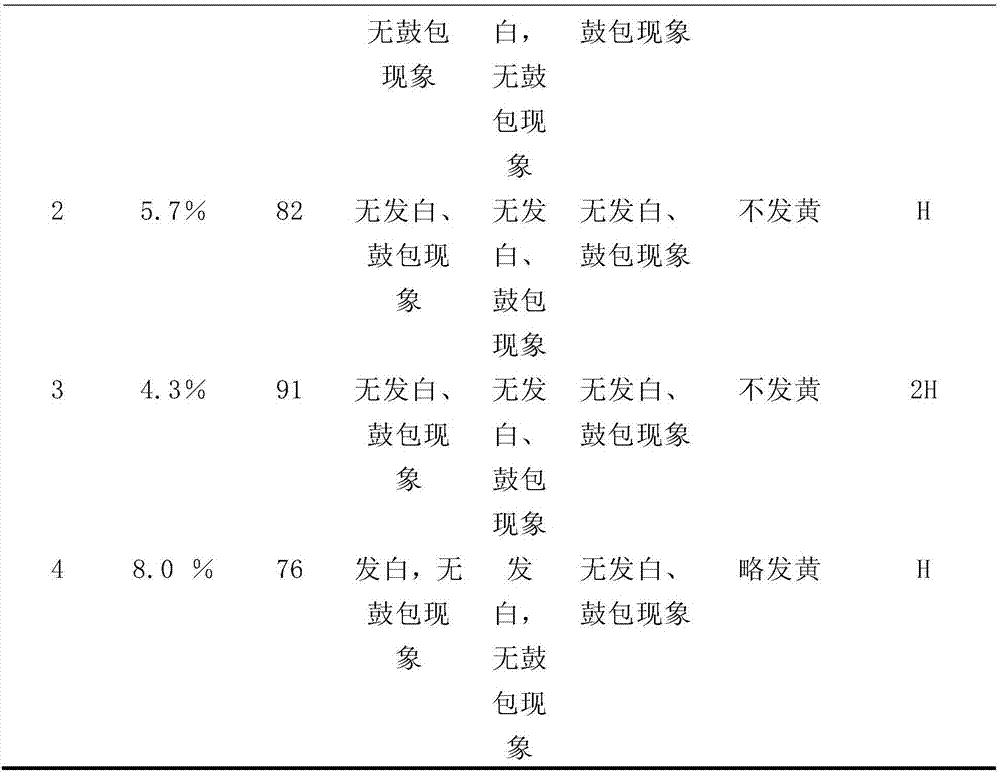

Examples

Embodiment 1

[0033] Prepare organosilicon-modified polyurethane / epoxy / acrylate composite emulsion, the method is as follows:

[0034] In the first step, add 50mL of epoxy resin diluted with butanol (E51) into a 250mL three-necked flask with stirring and heating functions, where the volume ratio of epoxy resin:butanol=1:3, and the epoxy Add 2.52g of ethylenediamine (EDA) at a time and stir at a medium speed for 1.5h at a molar ratio of the epoxy group in the resin to the amino group in ethylenediamine at a ratio of 1:3. ) after heating up to 70° C., removing excess ethylenediamine and solvent under vacuum conditions of 2-5 KPa to prepare an amino-terminated epoxy oligomer for future use.

[0035] In the second step, 6.23g of toluene diisocyanate (TDI) was added in a three-necked flask with stirring and heating functions under the protection of nitrogen, and the temperature was raised to 75°C, and 20.00g of polypropylene glycol 2000 (PPG) was added dropwise. After reacting for 0.5h, Gradual...

Embodiment 2

[0038] Adopt the method similar to embodiment 1 to prepare organosilicon modified polyurethane / epoxy / acrylate composite emulsion, difference is:

[0039] The first step: replace epoxy E51 in Example 1 with epoxy F51, and other conditions are the same as Example 1

[0040] Second step: replace toluene diisocyanate (TDI) in embodiment 1 with isophorone diisocyanate (IPDI), replace polypropylene glycol 2000 (PPG) in embodiment 1 with polytetrahydrofuran (PTHF), add organic silicon When γ-aminopropyltriethoxysilane (KH550) and the above-mentioned amino-terminated epoxy prepolymer, add 1.52g 1.4 butanediol (BDO), add 0.2g sodium dodecylsulfonate when emulsifying polyurethane , other conditions are with embodiment 1.

Embodiment 3

[0042] Prepare organosilicon-modified polyurethane / epoxy / acrylate composite emulsion, the method is as follows:

[0043] The first step: replace epoxy E51 in example 1 with epoxy E44, drop 0.4g triethylamine while adding ethylenediamine, other conditions are the same as example 1.

[0044] The second step: use KH560 to replace the organic silicon KH550 in the example, increase the amount of DMPA to 1.55g, add 5mL of acetone to reduce the viscosity when adding acrylic acid monomer, use ice water instead of deionized water at room temperature, and other conditions are the same as in Example 2 .

[0045] The third step: place the silicone-modified polyurethane / epoxy / acrylate composite emulsion obtained in the third step in a vacuum drying oven at 80° C., and dry for 5-8 hours to remove the acetone added before. Other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com